Cast-in-place pile construction method by adopting two retaining cylinders to transverse deep and thick gravel layer

A construction method and cast-in-place pile technology, which are applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of less construction equipment and high equipment purchase price, reduce engineering construction costs, ensure safe and reliable engineering quality, and facilitate the organization of construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

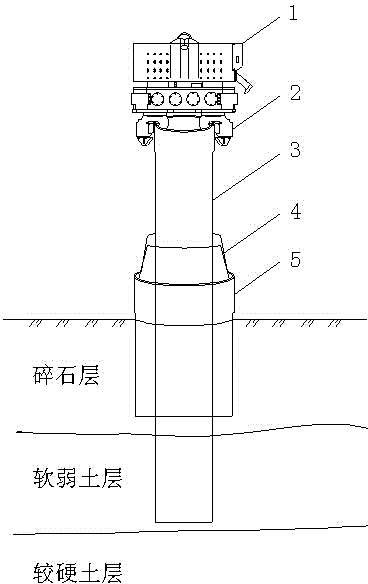

[0031] see now figure 1 , figure 1 It is a schematic diagram of the sinking of double casings in the construction of cast-in-situ piles according to the embodiment of the present invention.

[0032] The construction method of cast-in-situ piles using double casings of the present invention to penetrate deep gravel layers is characterized in that it includes the following steps:

[0033] a. Clamp the groove part of the outer steel casing 5 with the clamp 2 of the electric vibratory hammer 1, and vibrate and sink until it is flush with the ground; if the resistance is large, use the rotary excavator to take out the inner soil core and continue to descend Sink in place; the outer steel casing 5 is 10m long, 1.2m in inner diameter, and 15mm in wall thickness; the outer steel casing (5) is made of 16Mn steel, and reinforcing hoops are arranged at the upper and lower ends of the outer steel casing.

[0034] b. Use a rotary excavator to dig out the soil and rock cores in the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com