Rapid overhauling method for blast furnace hot air main pipe refractory lining

A hot blast main pipe and refractory lining technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of inability to operate blast furnaces, inconvenient methods for hot blast stove shutdown and maintenance, removal of refractory linings for shutdown maintenance, and re-laying, etc. problems, to achieve safe and reliable engineering quality, reduce maintenance engineering costs, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

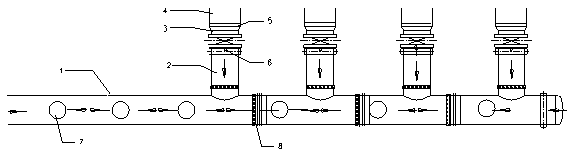

[0033] The construction process of the method for quickly overhauling the refractory lining of the blast furnace hot blast main pipe of the present invention: refractory bricks are hoisted to the hot blast main pipe platform → the blast furnace is shut down → the hot blast branch pipe connection short pipe is removed, the fire blocking blind plate and the fire blocking wall are installed → the old corrugated pipe of the hot blast main pipe Dismantling→cooling down→opening the upper part of the hot blast main pipe→removing the refractory lining of the hot blast main pipe and branch pipes→installing the new corrugated pipe of the hot blast main pipe→constructing the refractory lining of the hot blast main pipe→cleaning the construction area→removing the fire blind plate and the fire retaining wall→installing the hot air The branch pipe is connected to the short pipe → the oven heats up.

[0034] The method for quickly overhauling the refractory lining of the blast furnace hot bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com