Ladder rib for controlling spacing of vertical reinforcement of shear wall and using method thereof

A technology of vertical steel bars and ladder bars, applied in the directions of structural elements, building components, building reinforcements, etc., can solve the problem that it is difficult to ensure that the shear wall vertical bars do not deviate, the qualification rate of the steel bar spacing is difficult to control, and the construction progress is affected. problems, to achieve the effect of safe and reliable engineering quality, simple structure and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

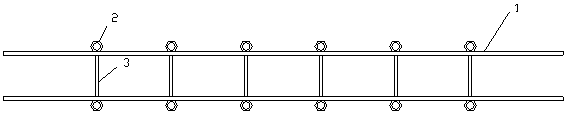

[0034] The ladder bar for controlling the vertical reinforcing bar spacing of the shear wall of the present invention comprises two horizontal ladder bars, some step bars, and some nuts.

[0035] see now figure 1 , figure 1 It is a structural schematic diagram of a ladder bar for controlling the vertical reinforcement spacing of a shear wall according to an embodiment of the present invention. As shown in the figure, the two horizontal ladder bars 1 are arranged parallel to each other, and the length of the horizontal ladder bars is the length of the shear wall section plus 100mm; the horizontal ladder bars use a steel bar one specification larger than the wall bars. The distance between two horizontal ladder bars = thickness of the shear wall - thickness of the protective layer * 2 - diameter of the horizontal steel bar of the shear wall * 2 - diameter of the vertical steel bar * 2 - diameter of the horizontal ladder bar - the difference between the size of the opposite side...

Embodiment 2

[0039] The using method of the ladder bar of the control shear wall vertical reinforcing bar spacing of the present invention, comprises the following steps:

[0040] a. Install the horizontal ladder bars 30cm above the top plate of the concrete formwork, which can be recovered and recycled after concrete pouring.

[0041] b. The spacing of the stepping bars is set according to the vertical reinforcement spacing of the shear wall. The stepping bars are welded to the inner side of the horizontal bars. The length of the stepping bars = the spacing of the horizontal ladder bars - the diameter of the horizontal ladder bars.

[0042] c. The hex nuts are welded on the outside of the horizontal bars, and the spacing is set according to the vertical steel bar spacing of the shear wall; the horizontal ladder bars and step bars are steel bars with a diameter larger than the steel bar of the shear wall.

[0043] d. When installing the steel bars of the shear wall, insert the vertical ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com