Construction method of exterior hidden frame supported glass curtain wall

A technology of hidden frame glass curtain wall and construction method, which is applied to walls, building components, buildings, etc., can solve the problems of complicated production process, high environment and equipment requirements, failure of glass curtain wall fixing devices, etc., and achieves safe and reliable engineering quality. Reasonable design specifications and valuable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

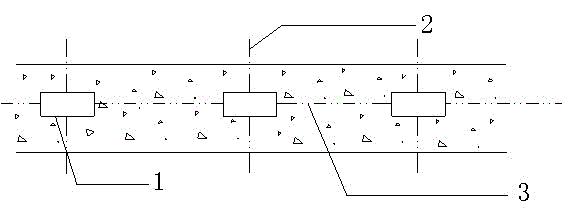

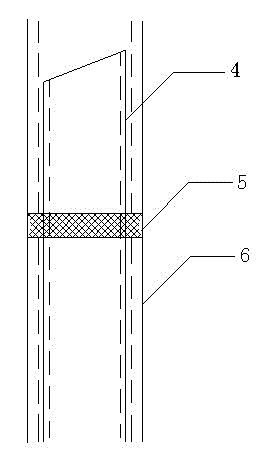

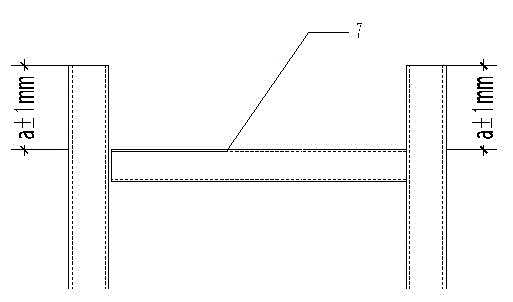

[0065] In 2014, the command building of the Kuwait Fire Department is a reinforced concrete frame structure, with G+6 floors above ground and a construction area of 22,000 square meters. The exterior wall is a fully hidden frame glass curtain wall with an area of 4,200 square meters. The construction sequence of the glass curtain wall with a fully hidden frame for the outer wall of the present invention: inspection of structure and embedded parts → setting out wires, popping up column grid lines, horizontal lines → installation of supports and columns → installation of beams → installation of lightning protection → heat preservation → interlayer fire protection →Concealed acceptance→Installation of glass briquettes→Glass installation→Gluing and cleaning.

[0066] According to the construction method of the glass curtain wall with full hidden frame for the outer wall, the structure of the glass curtain wall with the full hidden frame for the outer wall is that the glass is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com