A Construction Method of Prefabricated Beam Steel Bearing Plate Resistance Mesh Composite Floor

A technology of resistance net and steel bearing plate, which is applied in the direction of floors, buildings, building components, etc., can solve the problems of delaying the construction period of the steel bearing plate and insufficient stability of the steel bearing plate, and achieves high installation efficiency, convenient operation, and reduced usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

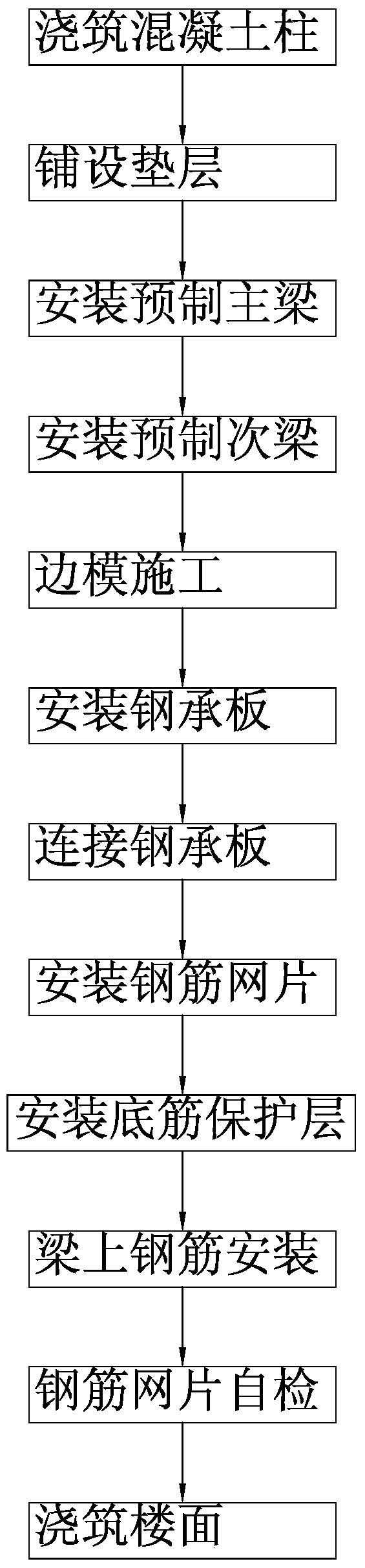

[0030] refer to figure 1 , a construction method for a prefabricated beam steel bearing plate resistance mesh combined floor, is characterized in that it comprises the following steps:

[0031] step a

[0032] 1. Pouring concrete column: cast-in-place concrete column 1 on the construction site;

[0033] 2. Lay the cushion: lay the concrete cushion between the poured adjacent concrete columns 1;

[0034] step b

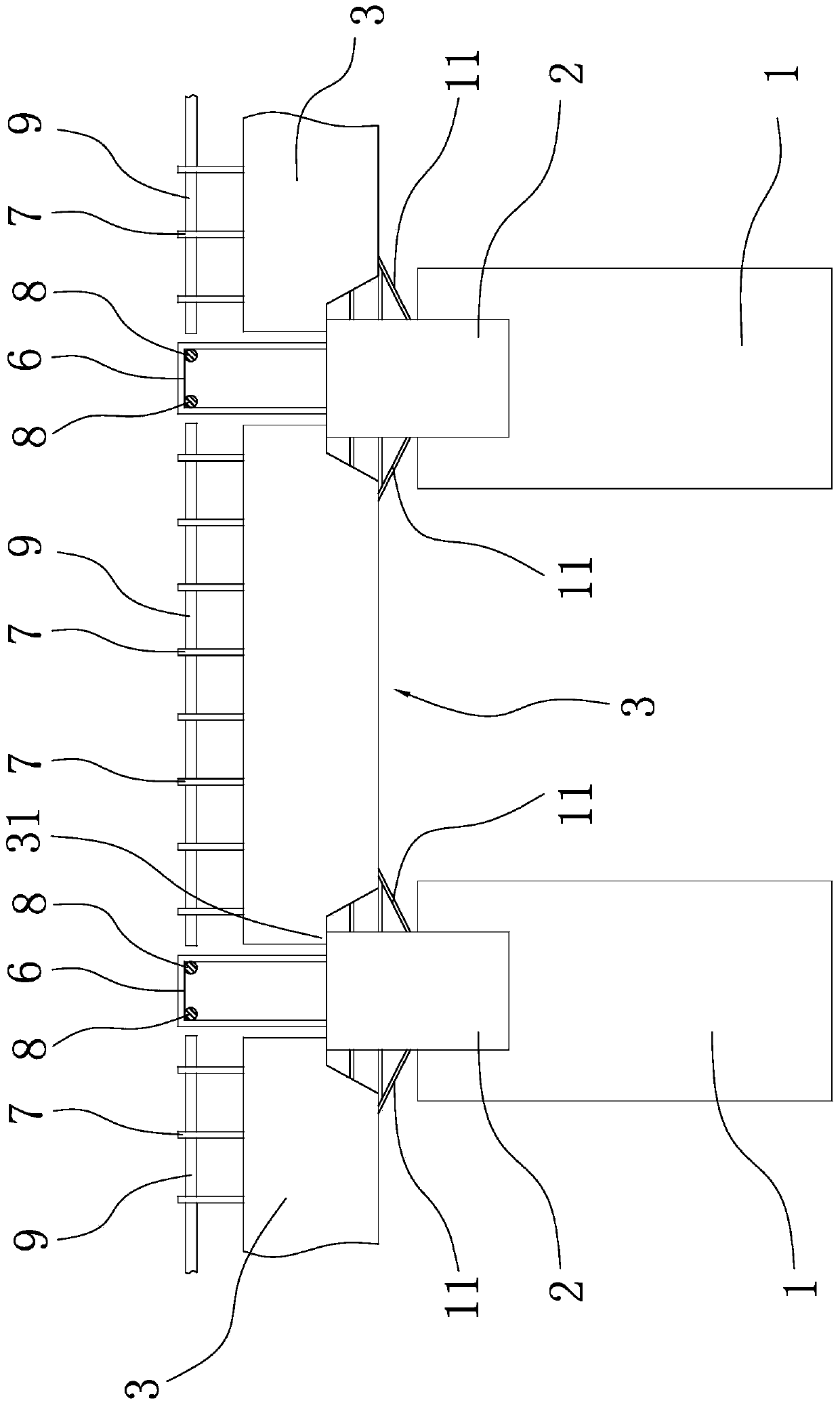

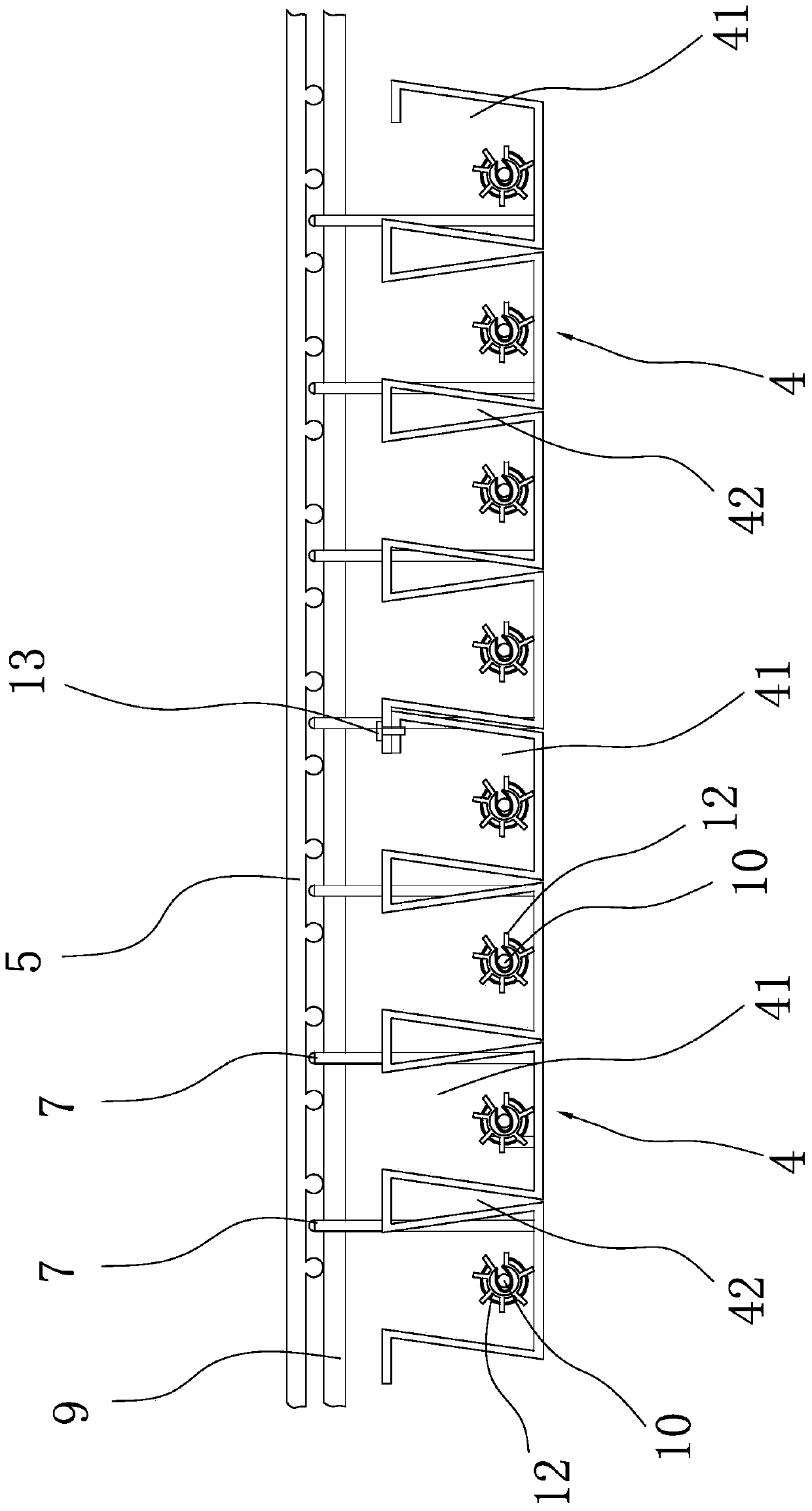

[0035] Install the prefabricated main beam: erect the two ends of the prefabricated main beam 2 on a concrete column 1 respectively. The prefabricated main beam 2 is a composite beam. Main beam stirrups 6 arranged in sequence in the length direction;

[0036] step c

[0037] 1. Install the prefabricated secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com