Construction method of mutilevel overpass scaffold

A multi-layer overpass bridge and construction method technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of bridge reinforced concrete pouring methods, high labor costs, and high construction costs, and achieve safe and reliable monitoring throughout the process. The effect of flexible methods and scientific monitoring methods

Inactive Publication Date: 2011-01-05

CHINA METALLURGICAL CONSTR ENG GRP

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the scaffolding construction of this overpass bridge is suitable for separate construction one by one, one by one, and one by one. Most designers and construction personnel believe that this kind of scaffold construction belongs to the existing mature construction technology, which is relatively safe in construction and has low construction difficulty. But also there are following deficiencies in the overpass scaffolding construction method of prior art: one, the bridge reinforced concrete pouring method is single, can only pour upwards gradually from the bottom layer, can't realize the simultaneous pouring of the upper and lower floors, so the construction period is long; two, one deck bridge pouring After forming, the scaffolding needs to be dismantled and rebuilt to the height of the bridge on the upper floor. In this way, the lower scaffolding needs to be repeatedly installed and disassembled, and the scaffolding takes a long time to build and the labor cost is high. It will cause traffic jams, and it is necessary to set up additional vehicle and pedestrian passages during erection; 4. Scaffolding monitoring uses a level gauge, which is carried out in time intervals, and cannot be monitored all-weather and on a full schedule at any time, and it is impossible to ensure that the entire construction process is under control; 5. Due to the large number of scaffolding construction on the main traffic road, there are many vehicles and people passing through, and there are great traffic hazards

Therefore, the construction of scaffolding in the above-mentioned manner not only needs to consider the passing roads of pedestrians and vehicles, but also has a long construction period, high construction cost, single construction method and inflexibility, and the monitoring of scaffolding is carried out according to experience.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

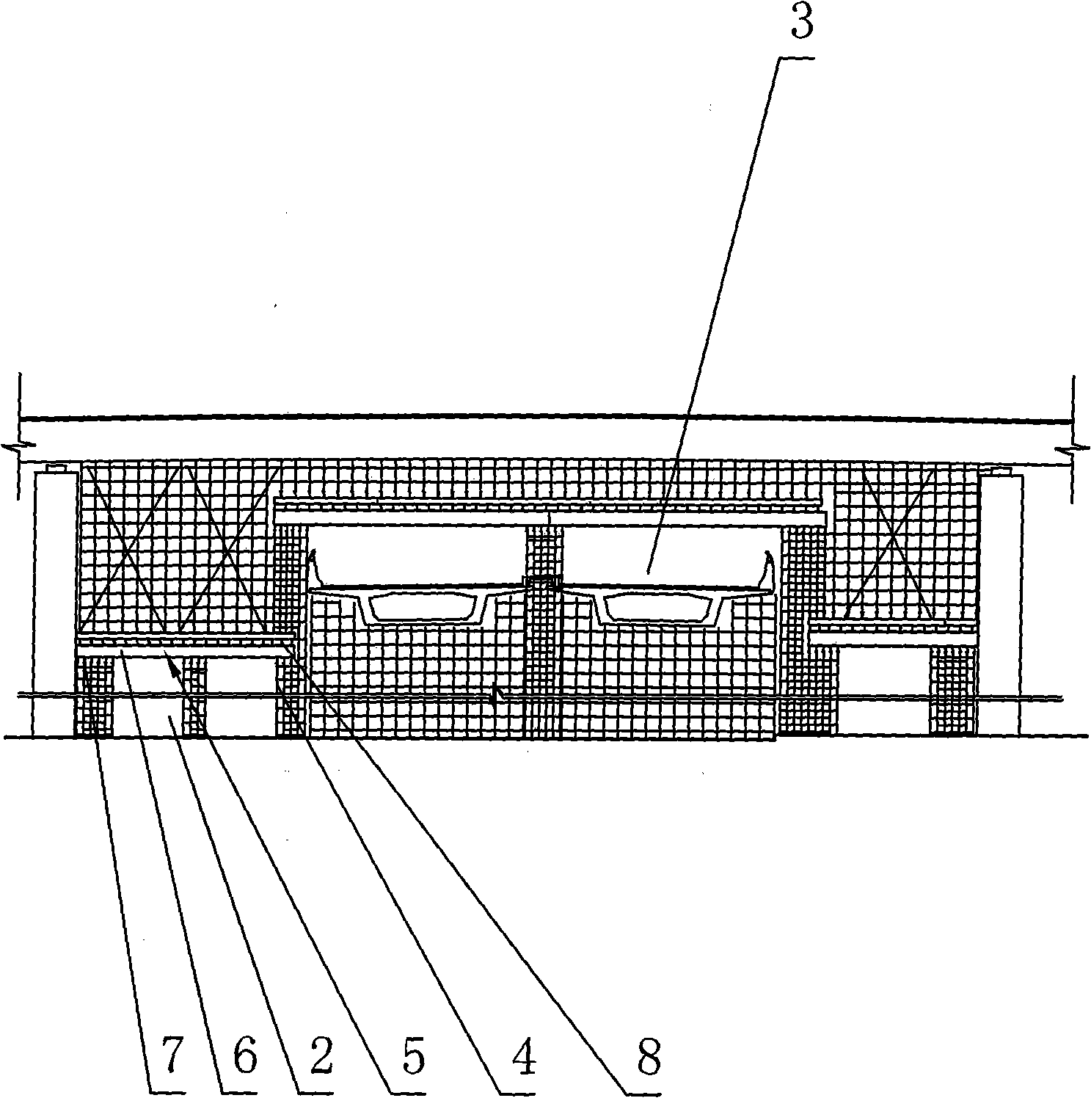

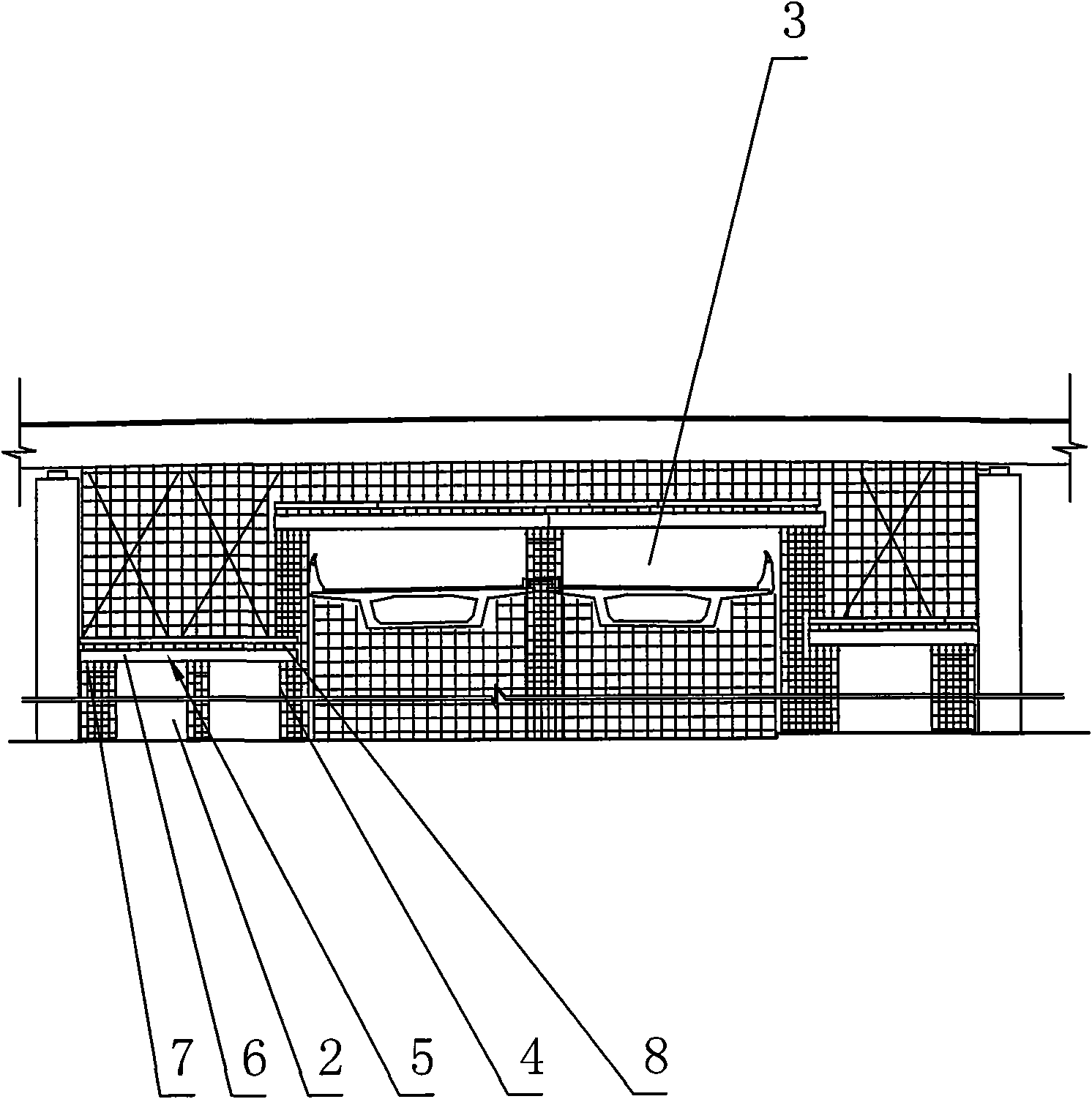

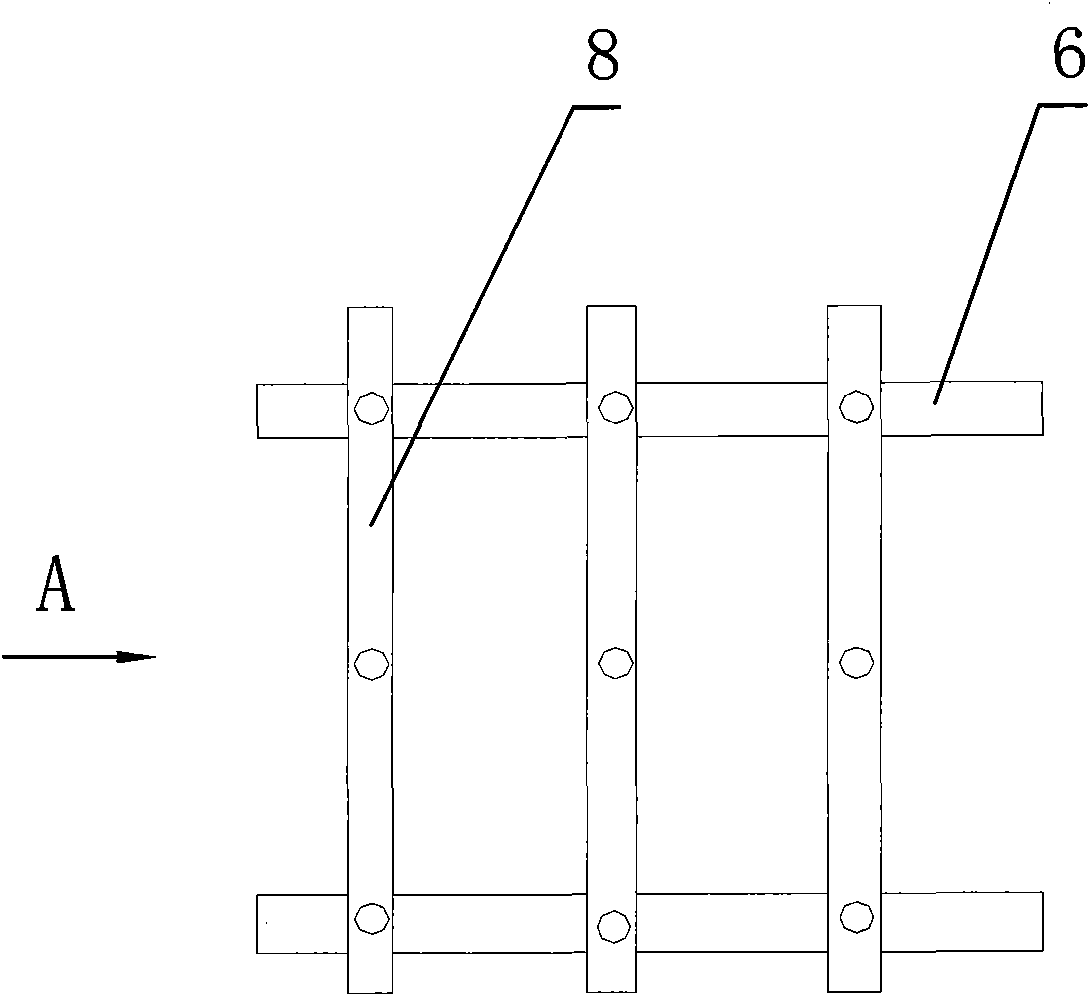

The invention discloses a construction method of mutilevel overpass scaffold, comprising the following steps: building a bottom layer scaffold provided with steel frame doorways for vehicles and pedestrians to pass, checking and installing a deformation monitoring system, and carrying out a load pressure test on the bottom layer scaffold; building at least two layers of bridge scaffolds on the bottom layer scaffold, building box girder doorways for bridge construction on the bridge scaffold, installing the deformation monitoring system on the box girder doorway and carrying out comprehensive load test. The bottom layer scaffold is provided with the steel frame doorway so as to meet the passing demand of big traffic flow; each layer of the middle part can be provided with the mutually crossed box girder doorways in the same plane and can be provided with the mutually crossed box girder doorways in the vertical direction, therefore optionally carrying out construction according to requirements; the whole scaffold only needs to be built and removed once, not only shortening the building and removing time of the scaffold but also reducing the risk of building and removing the scaffold; and each level of bridge can be constructed at the same time, and therefore, the construction period is short and the construction cost is low.

Description

Construction method of scaffolding for multi-storey overpass bridge technical field The invention relates to a method for constructing an overpass scaffold, in particular to a method for constructing a multi-layer overpass scaffold suitable for simultaneous construction. Background technique In the prior art, when building a multi-storey overpass, mostly adopt firstly to build the bottom scaffold, build the first floor bridge scaffold on the basis of the bottom scaffold, lay the formwork, cloth steel bars, pour concrete, after the first layer of bridge is poured and formed, dismantle the second For the bridge scaffolding on the first floor, re-build the scaffolding from the ground to the height of the bridge on the second floor. After the second-story scaffolding is built, formwork is laid, steel bars are laid, and concrete is poured, and so on. The height of a bridge. Therefore, the scaffolding construction of this overpass bridge is suitable for separate construction on...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04G1/00E01D21/00

Inventor 潘国英邓雄军潘津

Owner CHINA METALLURGICAL CONSTR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com