Construction method of settlement joint water seepage prevention system between frame bridge and retaining wall

A construction method and frame bridge technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of frame bridge walls and retaining walls, the inability to effectively prevent water leakage, and affect the appearance, etc. To achieve the effect of reducing the possibility of repairs affecting traffic operations, ensuring the effect of anti-seepage and ensuring the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The construction method of the anti-seepage system of the settlement joint between the frame bridge and the retaining wall provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples

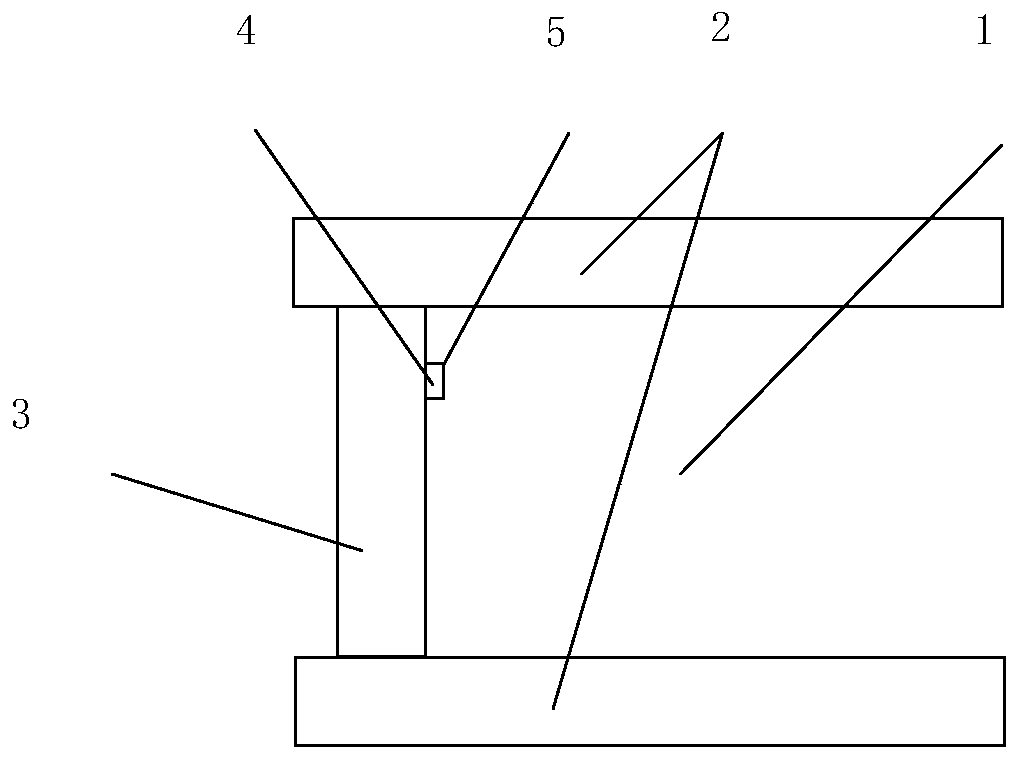

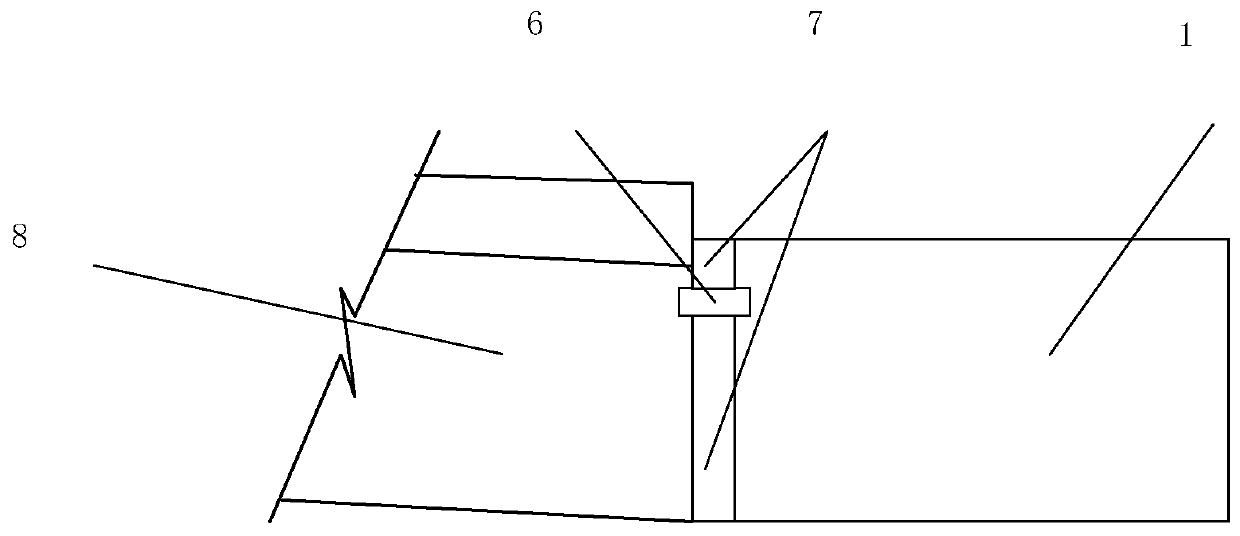

[0021] Such as figure 1 , figure 2 As shown, the construction method of the settlement joint anti-seepage water system between the frame bridge and the retaining wall provided by the invention comprises the following steps carried out in order:

[0022] 1) When it is necessary to carry out the construction of the wall body of the frame bridge and the wall body 1 of the edge patch wall, the construction personnel shall first bind the steel skeleton at the setting position of the frame bridge wall body and the edge patch wall body 1 according to the design requirements, and then A steel formwork 2 is arranged on the inner and outer sides of the reinforcement skeleton, and a wooden formwork 3 is arranged at the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com