Method for mounting continuous production line of non-oriented silicon steel

An installation method and a technology of oriented silicon steel, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of increasing construction costs, increasing construction costs, and long construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0116] The non-oriented silicon steel continuous production line installation method of the present invention is characterized in that comprising the following steps:

[0117] a. Fabrication and installation of "door" frame steel structure, including:

[0118] (1) Fabrication of "door" frame

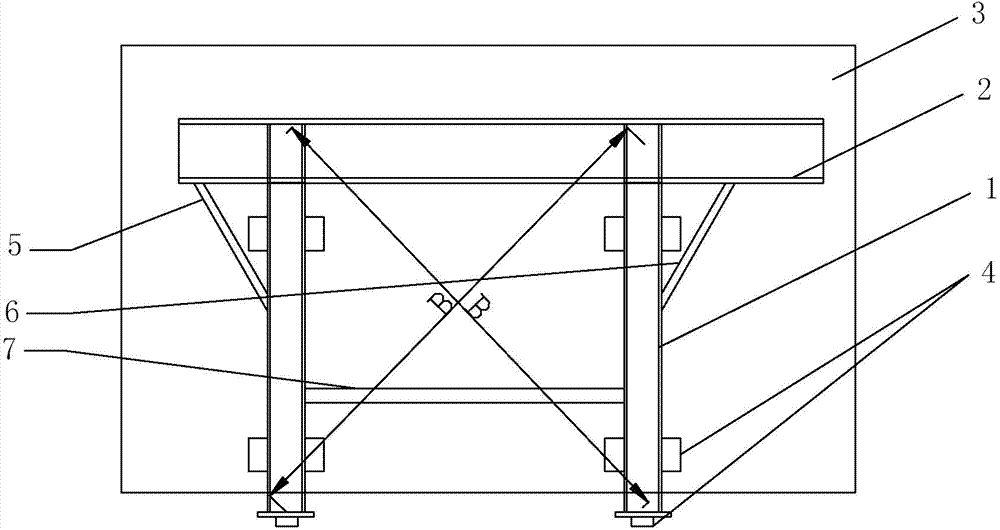

[0119] see now figure 1 , figure 1 It is a schematic diagram of the door frame structure of the embodiment of the present invention. As shown in the figure, the "door" frame consists of two steel columns 1 and a beam 2 welded to each other on a temporary assembly platform 3 to form a door-shaped steel member. Erection of the steel plate, adjust the elevation of the platform, and use a level to check that the level of the platform is controlled within 3mm; before welding, channel steel can be used as temporary supports 5, 6, 7, after welding, temporary supports 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com