Pile extracting sleeve and using method thereof

A pile sleeve and prefabricated technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of long pile pulling period, high price and high cost, and achieve fast pile pulling speed, convenient production, and pile pulling technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

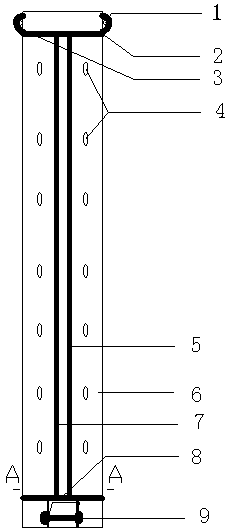

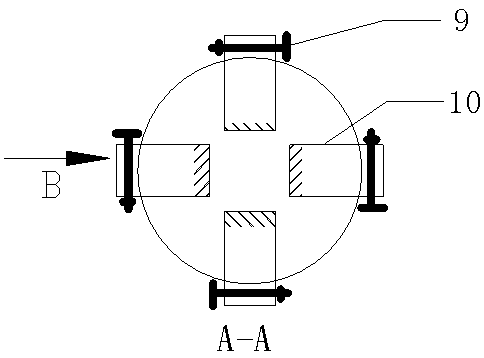

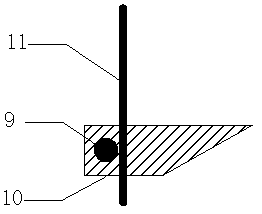

[0042] The pile sleeve of the present invention is used for pile extraction operations of concrete prefabricated square piles, and comprises steel pipes, four tongues, water pipes and air pipes.

[0043] see now Figure 1-3 , figure 1 It is a structural schematic diagram of the pile pulling sleeve of the embodiment of the present invention, figure 2 for figure 1 The sectional view of A-A in, image 3 for figure 1 Middle B direction view. As shown in the figure, the steel pipe body is a welded steel pipe with a lifting lug fixedly welded at one end. The specification of the welded steel pipe is 800*26mm, and the length of the welded steel pipe is 25m. root steel pipe, four steel pipes for 180 o Symmetrically arranged, the corresponding two are the water pipe and the air pipe, the length of the water pipe and the air pipe is the same as the length of the steel pipe body, one end of the water pipe and the air pipe is respectively installed with a high-pressure nozzle, and ...

Embodiment 2

[0046] The use method of the pile pulling sleeve is used for the pile pulling operation of the concrete prefabricated square pile, including the following steps:

[0047] a. Preparatory work before pulling piles

[0048] (1) Organize relevant foremen, technicians and construction teams to be familiar with the construction drawings, and organize the self-examination, joint examination and technical disclosure of drawings before the start of construction.

[0049] (2) Do a good job of material planning, machinery and equipment planning, labor planning, construction progress planning, and prefabricated pile pulling sleeves before the start of construction.

[0050] (3) Site leveling: Use crawler cranes to walk the road for pulling out piles for compaction, and lay steel plates or roadbed boxes to ensure the safety of crawler cranes.

[0051] b. Determine the position of the pile head: According to the design position of the pile position, excavate the trench and expose the pile he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com