Large-span steel structure roof sliding method for electronic factory building

A technology for electronic workshops and steel structures, applied to truss structures, girders, roofs, etc., can solve the problems of unsatisfactory cranes and damage to concrete structures, etc., and achieve the effect of practical sliding technology, convenient manufacture, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for sliding the large-span steel structure roof of the electronic factory building according to the present invention has a span of 120m and a sliding length of the steel structure roof of 170m. The crane or use the original structure to slide, including the following steps:

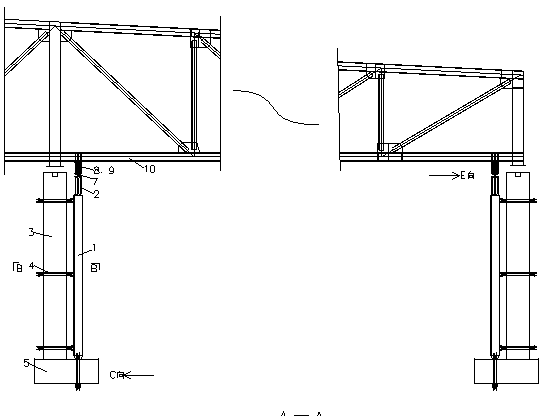

[0039] 1. Set up a φ351*10mm steel pipe column 1 next to the inner side of the second-floor concrete column at the base of each roof steel structure truss on both sides of the span of the factory building. The steel pipe column is used for sliding track beam installation.

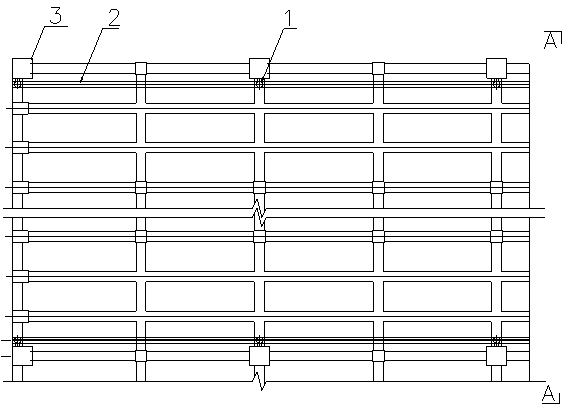

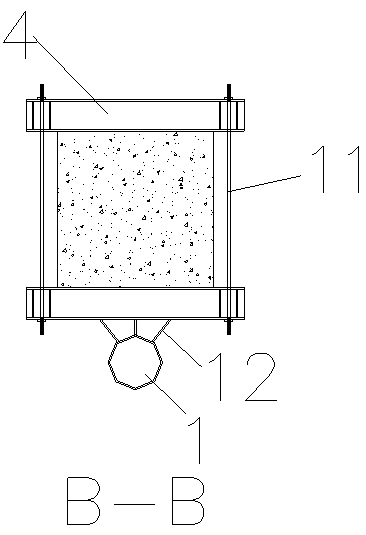

[0040] see now Figure 1-4 , figure 1 It is a schematic diagram of the sliding plane of the embodiment of the present invention, figure 2 for figure 1 The sectional view of A-A in, image 3 for figure 2 The sectional view of B-B in, Figure 4 for figure 2 Middle C direction view. As shown in the figure, the height of the two-story concrete column 2 is 8m, and the height of the steel pipe column 1 is 7.05m....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com