Desulphurizing tower bottom replacing method employing Jig frame bearing

A replacement method and desulfurization tower technology, applied in building maintenance, construction, building construction, etc., can solve problems such as high construction difficulty, high tower, self-heavy, etc., and achieve safe and reliable project quality, good use effect, and convenient production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for replacing the bottom of a desulfurization tower with tire frame load-bearing is characterized in that it comprises the following steps:

[0038] a. Isolate the desulfurization tower and clean up the combustibles in the tower

[0039] The desulfurization tower is 40 meters high, 8.7 meters in diameter, and weighs 140 tons. The bottom 2 meters below is severely corroded and leaks, and needs to be replaced. Before the bottom is replaced, the whole device is an independent system, so it is necessary to remove all the pipes, instruments, and support platforms connected to the desulfurization tower, and all pipes must be isolated with valves and blind plates after purging and replacement. Open the manhole of the desulfurization tower, in order to reduce the weight of the tower body, it is also necessary to clean up the packing and sulfur in the tower;

[0040] b. Fabrication and welding of tire frame

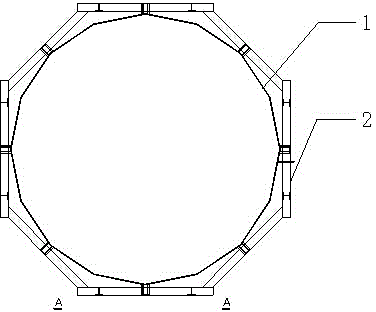

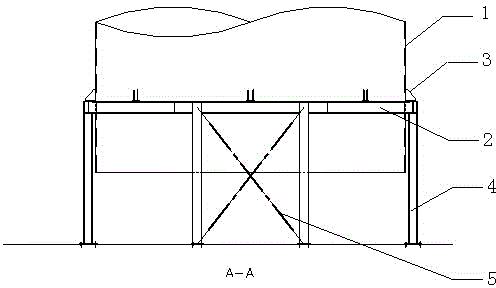

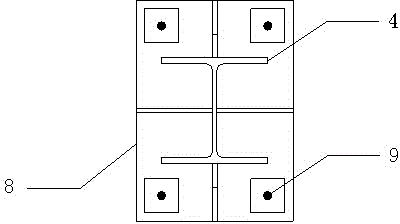

[0041] see now figure 1 and figure 2 , figure 1 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com