Deformation joint formwork erection construction method

A construction method and technology of deformation joints, which are applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of inconvenient laying of deformation joint formwork, difficulty in ensuring project quality, and increase in project cost, etc. Achieve safe and reliable engineering quality, solve installation and dismantling difficulties, and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The deformation joint formwork construction method of the present invention is applicable to wall structure expansion joints, comprising the following steps:

[0030] a. Calculate the wall area at the construction joints according to the construction drawings, and at the same time determine the use of wood formwork according to the formwork material supplied on site; the material of the wood formwork is plywood 6 with a thickness of 12mm.

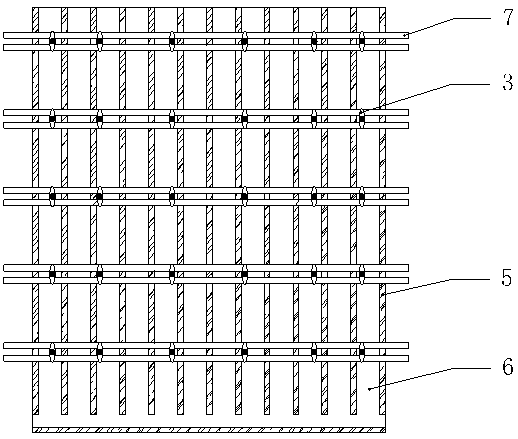

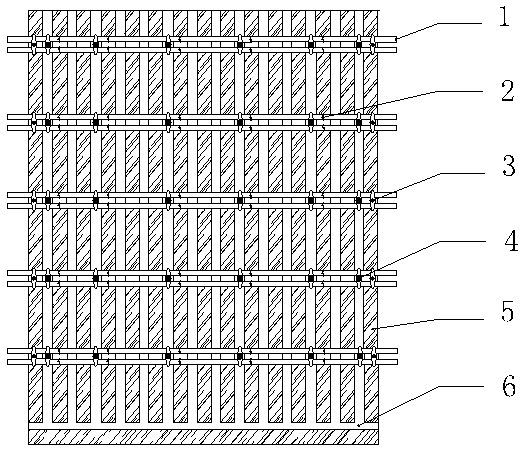

[0031] b. Formwork production inside the wall: please refer to figure 1 , figure 1 It is a structural schematic diagram of the formwork inside the wall according to the embodiment of the present invention. According to the height and width of the wall, lay the wooden formwork of the corresponding area on the ground, use 13 pieces of 40×90mm wooden squares 5 whose length is equal to the height of the wall, and lay the wooden squares vertically and parallel to each other on the wooden formwork. 200mm, 5 Ф48mm double steel pipes are a...

Embodiment 2

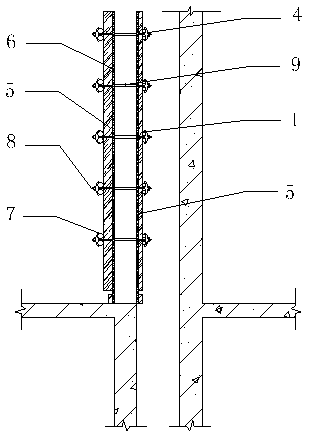

[0037] image 3 It is a schematic diagram of the installation of the deformation joint formwork according to the embodiment of the present invention, and it is also a schematic diagram of batch pouring on both sides when the distance between the deformation joints is too small.

[0038] When the distance between the deformation joints is too small, the installation of the deformation joint formwork adopts batch casting of units on both sides, that is, after the strength of the first poured side meets the requirements, the formwork is removed and the other side is poured.

[0039] The present invention has substantive features and significant technical progress. The deformation joint formwork construction method of the present invention is easy to manufacture and can be produced using on-site materials without the need to purchase other materials. The integral laying is not only convenient for installation, It can also be dismantled as a whole, and the operating efficiency is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com