Method for overhauling fire-resistant material for annular air duct and chute in coke dry quenching furnace

A technology of refractory materials and CDQ, which is applied in coking ovens, lining repair, petroleum industry, etc., can solve problems such as short life of CDQ furnace lining, waste of refractory materials and construction costs, and collapse, so as to achieve safe and reliable project quality, Reduce engineering construction cost and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

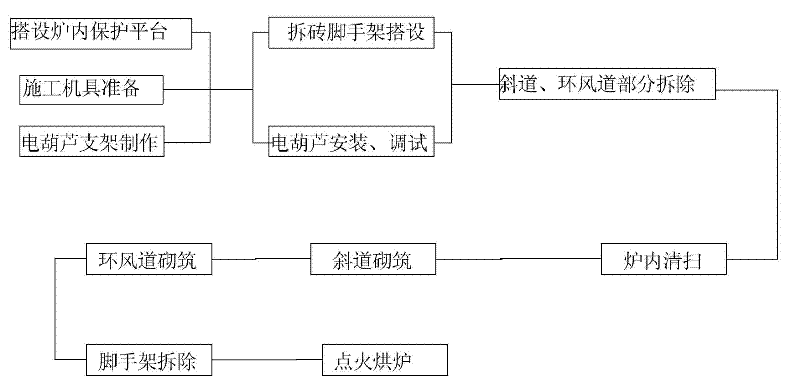

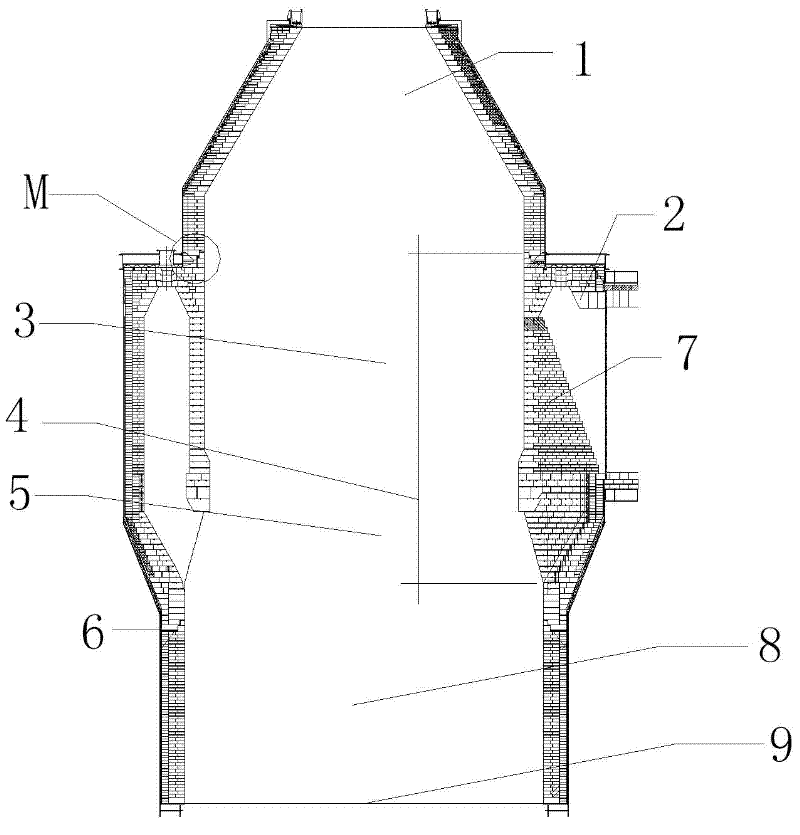

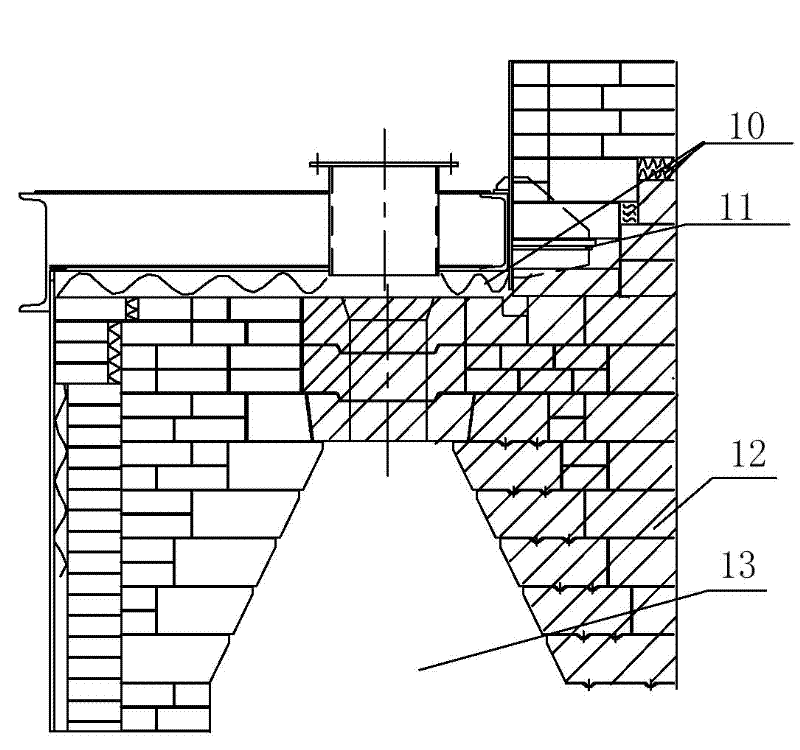

[0044] exist Figure 1 ~ Figure 3 middle, figure 1 It is a block diagram of the maintenance and construction process of CDQ furnace ring air duct and ramp refractory materials in the embodiment of the present invention, figure 2 It is a schematic diagram of the CDQ furnace structure of the embodiment of the present invention, image 3 for figure 2 Partial enlarged view of M in middle. As shown in the figure, the upper shell 1 is located in the top area of the CDQ furnace, the air circulation duct 3 is below the upper shell 1, the chute 5 is below the air circulation duct 3, and the demolition and construction area 4 indicates this Invention is the main area of the CDQ furnace ring air duct and ramp refractory maintenance and construction work, and the opening partition wall 7 is located in this area.

[0045] The CDQ furnace ring air duct and ramp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com