Construction method for shear wall setting steel framework bracing unidirectional fastening screw on deformation joint

A technology for tightening screws and construction methods, applied in the processing of building materials, construction, building structure, etc., can solve the problem that the flatness, verticality, concrete compactness, and shear wall formwork at deformation joints of shear walls cannot be guaranteed. The problems of inconvenient support method and unsatisfactory quality of shear wall at deformation joints have achieved the effect of safe and reliable engineering quality, simple structure and reduced engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

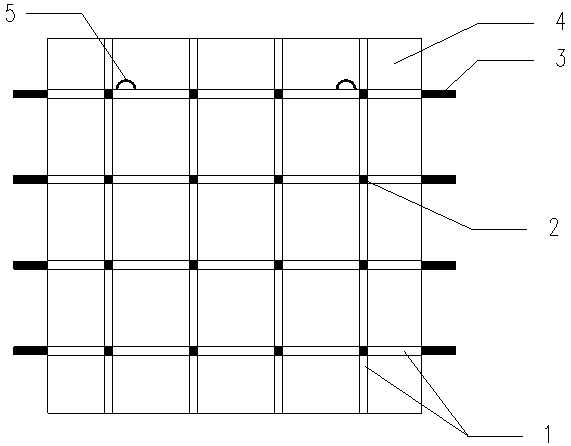

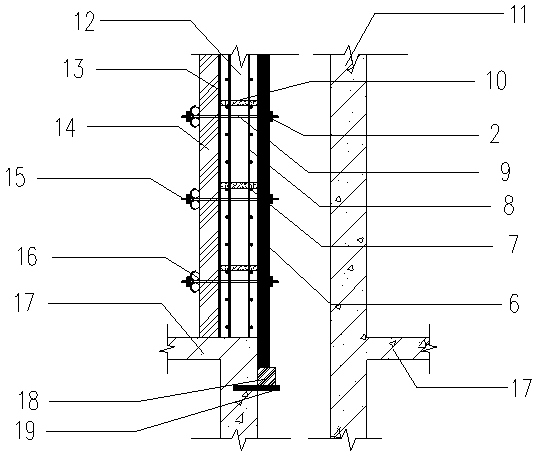

[0033] The technical process of the construction method of the shear wall shaped steel formwork supporting the one-way fastening screw at the deformation joint of the present invention: template making (shear wall shaping steel mold making, wooden mold making) → vertical steel bar binding → steel bar acceptance → formwork assembly Positioning (the wooden formwork is in place first, and then the steel formwork is in place) → formwork reinforcement (penetrate the tension screw to reinforce the wooden formwork and steel formwork) → formwork acceptance → concrete pouring.

[0034] According to the construction method of the present invention for supporting the shaped steel formwork of the shear wall at the deformation joint, the shear walls on both sides of the deformation joint are based on the poured floor slabs of the same height, and the shear wall 11 on one side has been poured. The other side of the shear wall 12 to be poured is provided with a one-way fastening screw, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com