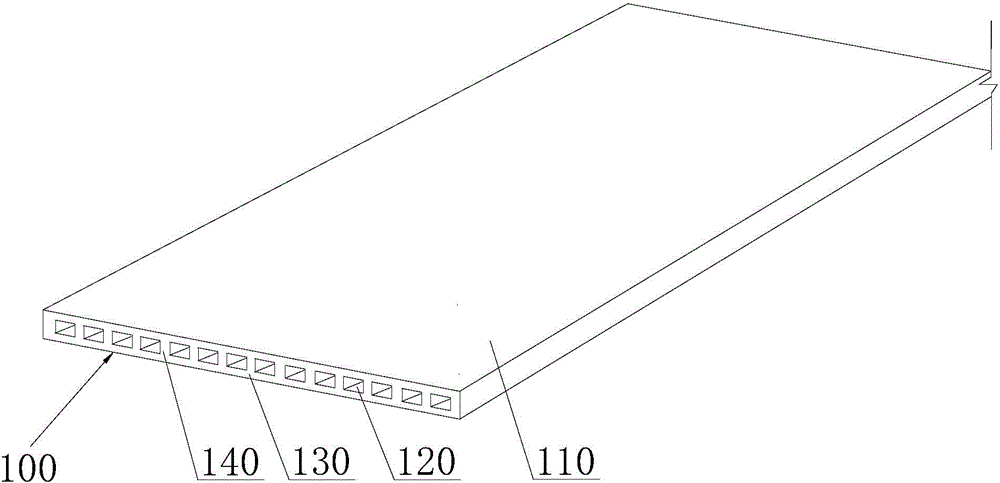

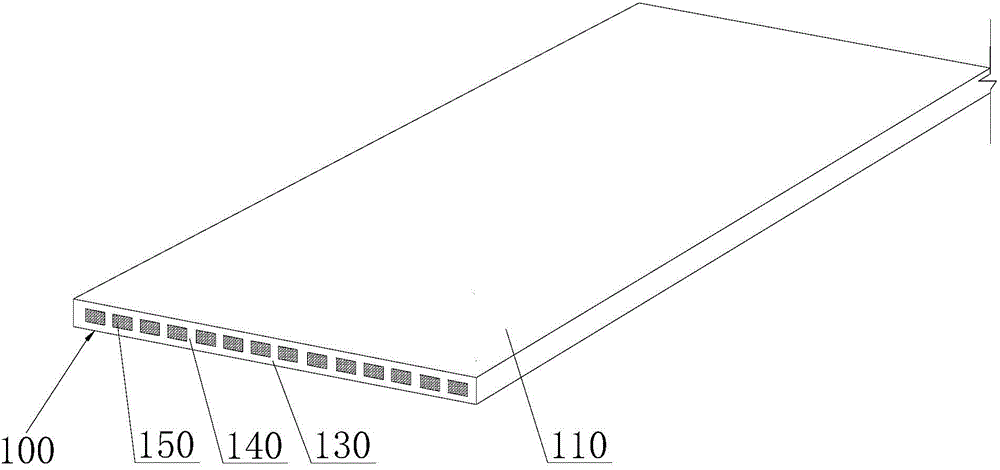

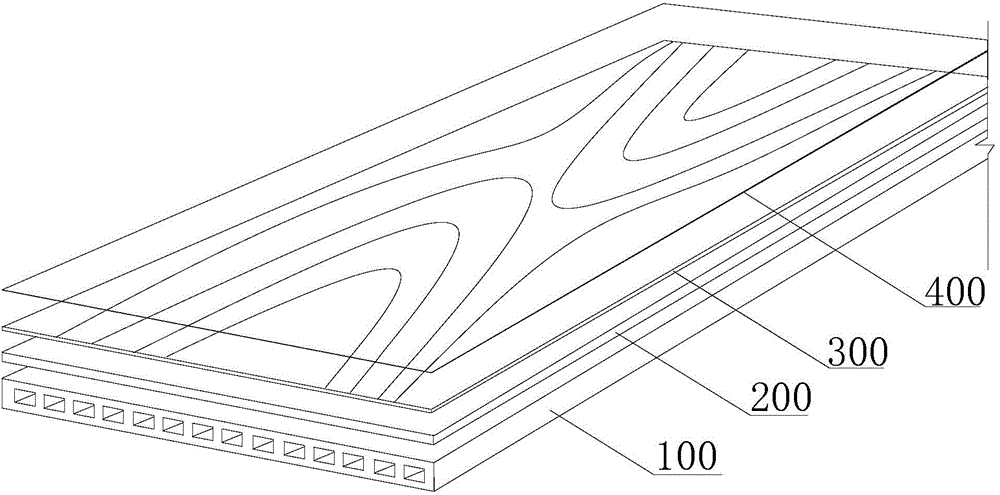

Hollow board and composite board

A hollow and composite material technology, applied in the field of sheet metal manufacturing, can solve the problems of high cost, selection of foaming materials, high foaming process requirements, and reduced product quality, etc., to achieve material saving, good waterproof effect, and high market share. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Calculated in parts by weight, the components of the PVC composite material are: 45 parts of PVC (8 parts containing CPVC); 60 parts of calcium carbonate; 2.4 parts of toughening agent CPE; 1.1 parts of lubricant (0.55 parts of stearic acid+PE wax 0.55 parts); 2.1 parts of stabilizer (1.05 parts of calcium stearate + 1.05 parts of zinc stearate); 0.1 part of toning powder; no added plant fiber. The composition distribution of this embodiment is relatively balanced, and a relatively neutral (relative to other embodiments) excellent product can be obtained.

Embodiment 2

[0039] Calculated by weight, the components of the PVC composite material are: 55 parts of PVC (5 parts containing CPVC); 70 parts of calcium carbonate; 3.6 parts of toughening agent ACR; 0.9 parts of lubricant (0.45 parts of stearic acid+PE wax 0.45 parts); 2.3 parts of stabilizer (1.15 parts of calcium stearate + 1.15 parts of zinc stearate); 0.01 part of toning powder; no added plant fiber. This embodiment basically does not have color toning, and is suitable for occasions such as plate core boards and substrates.

Embodiment 3

[0041] Calculated in parts by weight, the components of the PVC composite material are: 48 parts of PVC (7 parts containing CPVC); 60 parts of calcium carbonate; 3.1 parts of toughening agent ACR; 1.0 parts of lubricant (0.5 parts of stearic acid+PE wax 0.5 part); 2.0 parts of stabilizer (1 part of calcium stearate + 1 part of zinc stearate); 0.04 part of toning powder; no added plant fiber. In this embodiment, the ratio of PVC component and calcium carbonate is low, and the toughness is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com