Cross wall segment guide rail bracket installation method

An installation method and technology of guide rail frame, which are applied in the directions of transportation and packaging, ship parts, ships, etc., can solve the problems of multiple installation datums, unable to guarantee the dimensional accuracy of the distance between the transverse wall, bow and aft guide rails, etc., to ensure the squareness and verticality, Distortion-free, well-positioned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

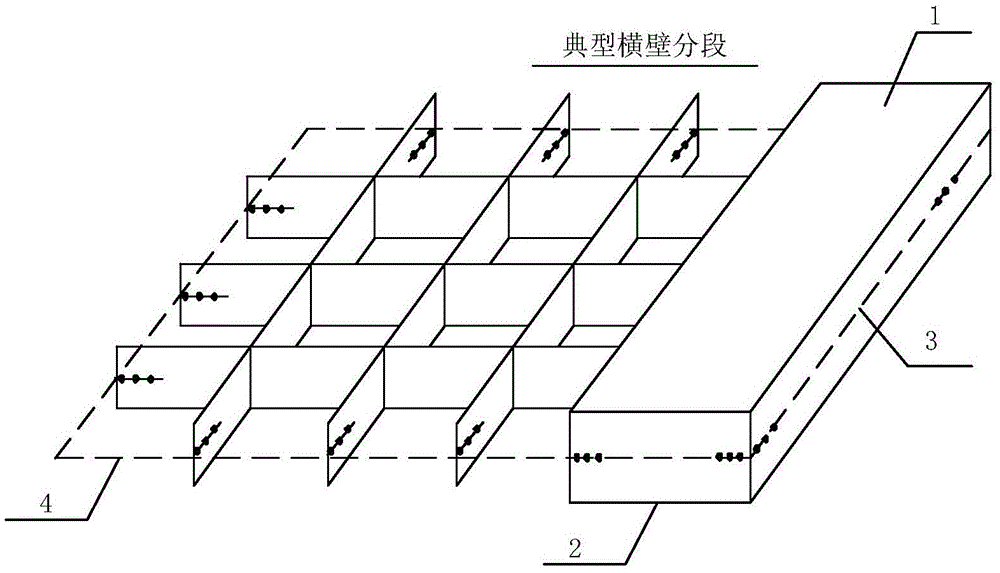

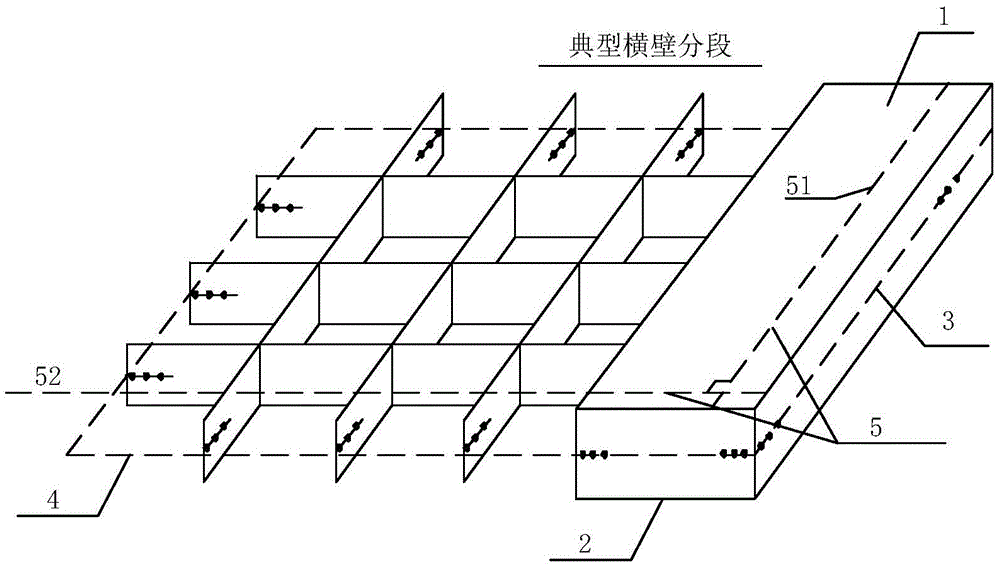

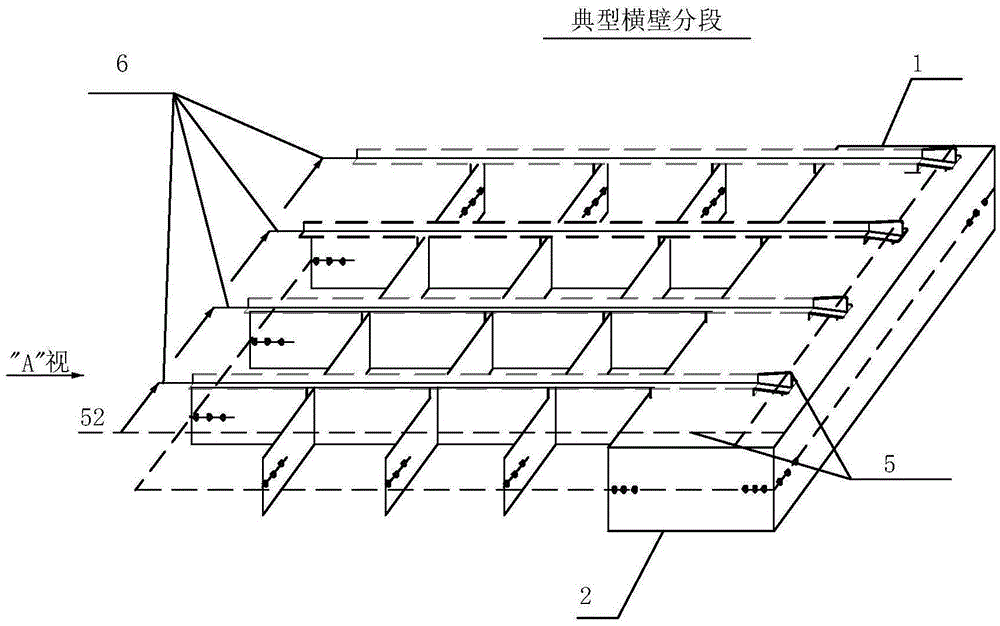

[0031] Figure 1~6 It is a schematic diagram of the operation of each step of the installation method of the cross-wall sectional guide rail frame of the present invention. The specific implementation method of the installation method of the cross-wall sectional guide rail frame of the present invention is as follows:

[0032] 1. Optimize the level of the bow surface 1 and the stern surface 2 of the transverse wall section; select a number of reference points of the middle surface on the side walls adjacent to the bow surface 1 and the stern surface 2, and set the marks of the gun seal; the reference points of the middle surface Located on the horizontal median line of the side wall; connecting the middle plane datum point to obtain the central datum line 3, the horizontal plane where the central datum line 3 is located is the middle plane 4; as figure 1 shown.

[0033] 2. Use a laser theodolite or a total station to draw a cross reference line 5 on the edge of the bow surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com