Assembled monolithic shear wall building structure and construction method thereof

A technology of building structure and shear wall, applied in the direction of building structure, building components, buildings, etc., can solve the problems of affecting normal use, easy to crack, affecting mechanical performance, etc., to reduce management costs, avoid joint cracking, Avoid the effects of reinforcement works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

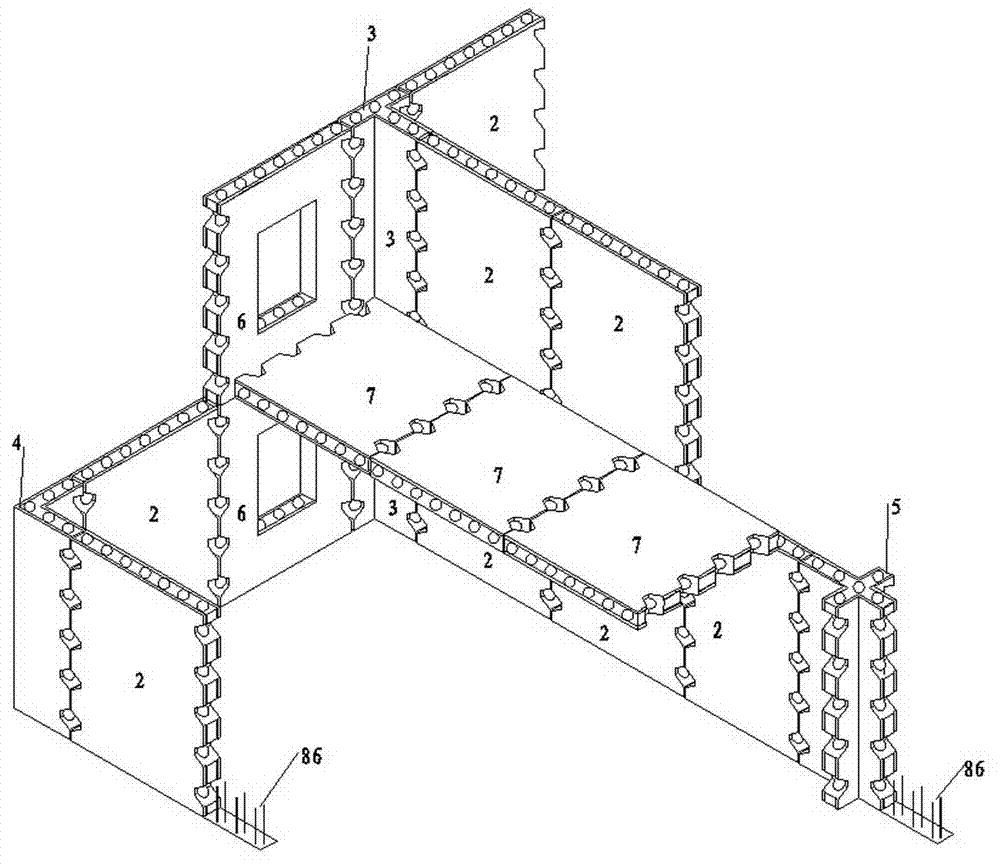

[0055] Examples of the present invention are figure 1 , this embodiment is a three-dimensional example diagram of a local layer of a high-rise shear wall building structure. The building structure includes: a prefabricated wall panel component 2 , a T-shaped wall column component 3 , an L-shaped wall column component 4 , a cross-shaped wall column component 5 , a wall component 6 with a hole and a floor slab component 7 . The wall panel component, the floor panel component and the wall column component are provided with several longitudinal through holes parallel to each other along the length direction, and transverse grooves intersecting at least one longitudinal hole are arranged at intervals on the longitudinal edges. The wall column components, wall panel components and wall components with openings are erected and placed to form a vertical load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com