Insulating mortar strengthening layer rowlock wall with steel wire mesh for setting hose tooth constructional column and manufacturing method thereof

A technology of thermal insulation mortar and layer empty bucket wall, which is applied in the direction of building structure, walls, building components, etc., can solve the problems of poor thermal insulation performance, poor earthquake resistance, and damage to farmland, so as to improve earthquake resistance, save materials, and strengthen The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

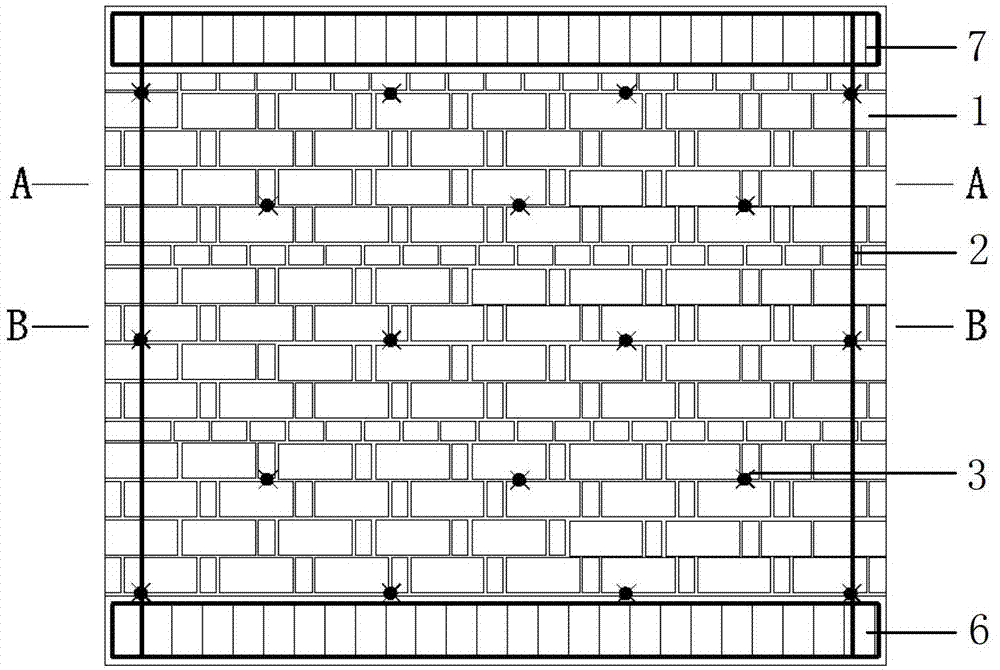

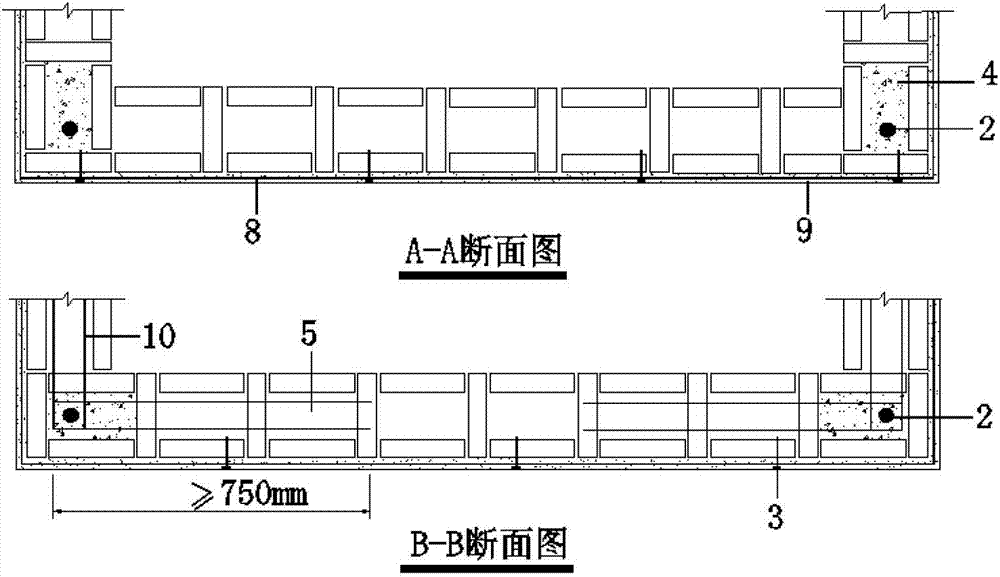

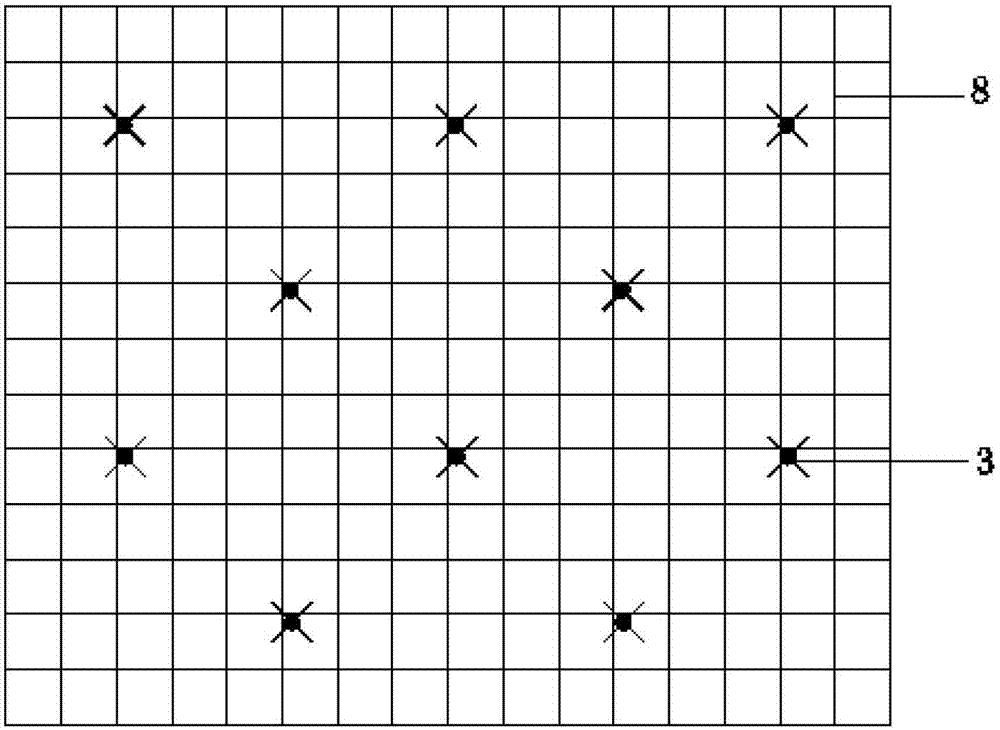

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the empty bucket wall structure with horse-toothed structural columns and steel wire mesh insulation mortar reinforcement layer of the present invention includes horse-toothed structural columns 4, reinforced concrete ring beams 7, wall body and outer wall surface insulation mortar 9 composite galvanized steel wire mesh Sheet 8, which is characterized in that: the wall is made of recycled concrete bricks 1 of standard size through flat laying, side laying or vertical laying to form a cavity 5, and a horse-toothed bridge is built at the intersection of vertical and horizontal walls and inner and outer walls. In the vertical hole, a vertical structural bar 2 is set at the center of the vertical hole and concrete is poured to form a horse tooth structural column 4; the lower end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com