Error correction method for measuring datum and structural benchmark of tri-axial magnetic sensor

A technology of measurement reference and error correction, which is applied in the field of testing, can solve the problems of large structure of magnetic detector itself and low correction precision, and achieve the effect of good repeatability and high correction precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] The present invention will be described in further detail below in conjunction with the accompanying drawings.

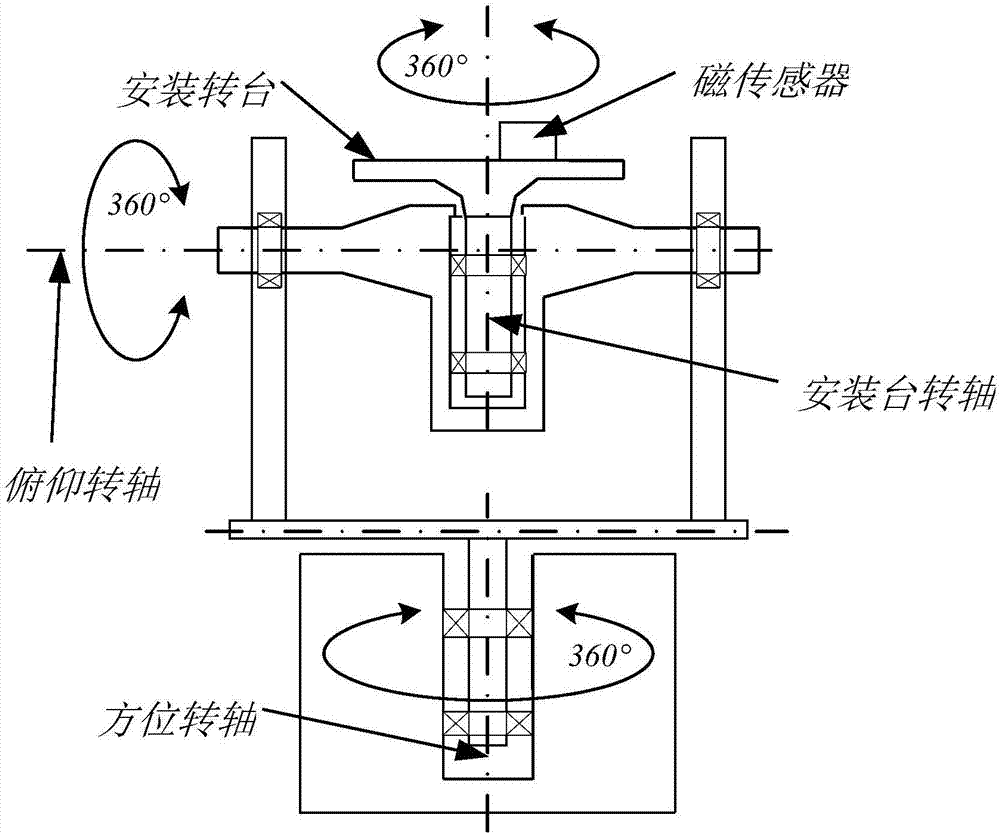

[0089] The invention proposes a digital correction method to eliminate the errors among the measurement reference, the structure reference and the installation reference of the three-axis magnetic detector. figure 1 It is a schematic diagram of the structure and function of the three-axis non-magnetic turntable, and the three-axis magnetic detector and the three-axis non-magnetic turntable need to meet the following conditions:

[0090] 1. The three-axis magnetic detector can detect three weak magnetic field vector values in orthogonal directions;

[0091] 2. The three-axis magnetic detector has completed the temperature drift coefficient calibration, that is, the three-axis magnetic detector has been calibrated and corrected the deviation of the three-axis magnetic measurement value introduced by its own temperature change;

[0092] 3. The three-axis mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com