Automatic fishing rod type hoisting device

A technology for hoisting equipment and fishing rods is applied in the field of automatic fishing rod hoisting equipment, which can solve the problems of limited lifting height, large equipment volume and high maintenance cost, and achieve the effects of low cost, small equipment volume and long stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

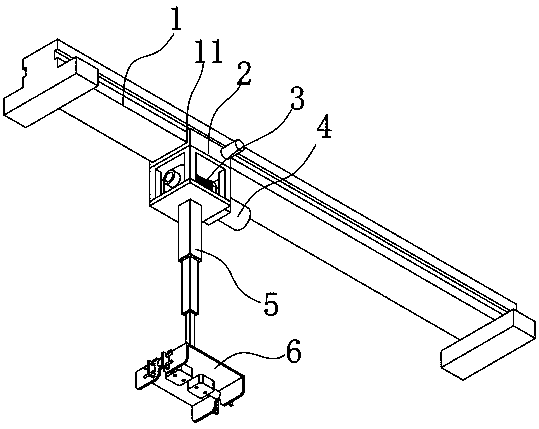

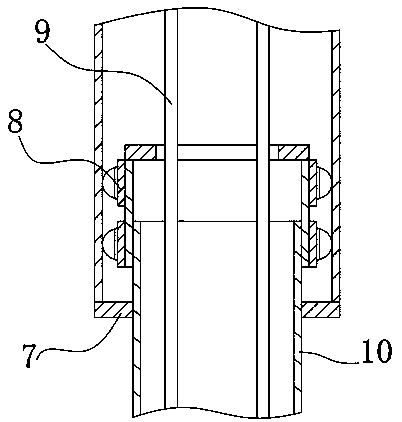

[0022] Embodiment 1: An automatic fishing rod type lifting device, comprising a horizontal beam 1, a trolley 2 arranged on the beam 1 and moving along the beam 1, the bottom of the trolley 2 is provided with a vertical Telescopic sleeve 5, said telescopic sleeve 5 is made up of a plurality of hollow tubes 10 connected end to end, each hollow tube 10 top is inserted into a hollow tube 10, and the bottom of the hollow tube 10 at the bottom of said telescopic sleeve 5 is provided with There is a spreader 6, and the trolley 2 is provided with a winch, and a hoisting rope 9 is wound on the hoisting machine, and the free end of the hoisting rope 9 is connected to a hollow tube 10 at the bottom of the telescopic sleeve 5 .

[0023] In the above design, the hoist is used to lift the spreader 6. The stroke is long, the equipment is small in size, and the cost is low. The telescopic sleeve 5 is used to effectively prevent the spreader 6 from shaking, ensure the stability during the hoist...

Embodiment 2

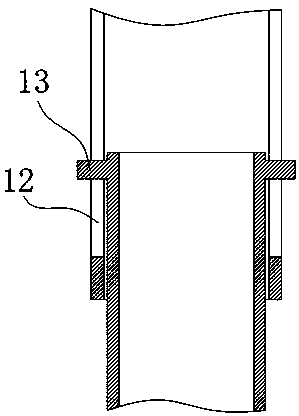

[0032] Embodiment 2, the difference between this embodiment and Embodiment 1 is that the hollow tube 10 is a circular tube, the top of the hollow tube 10 is provided with a guide pin 13, and the side of the hollow tube 10 is provided with a 10 a bar-shaped guide hole 12 extending in the direction of the generatrix, and the guide pin 13 cooperates with the bar-shaped guide hole 12 on the matching hollow tube 10 . The structure is simple, the cost is low, and it has good anti-rotation and anti-shaking effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com