Box packing system of liquid transfer gun head

A gun tip box and boxing technology, which is applied in packaging and other directions, can solve the problems that the gun tip cannot be accurately inserted into the gun tip hole, the structure is complex, and the box cover does not automatically close, so as to reduce the damage rate and improve the boxing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

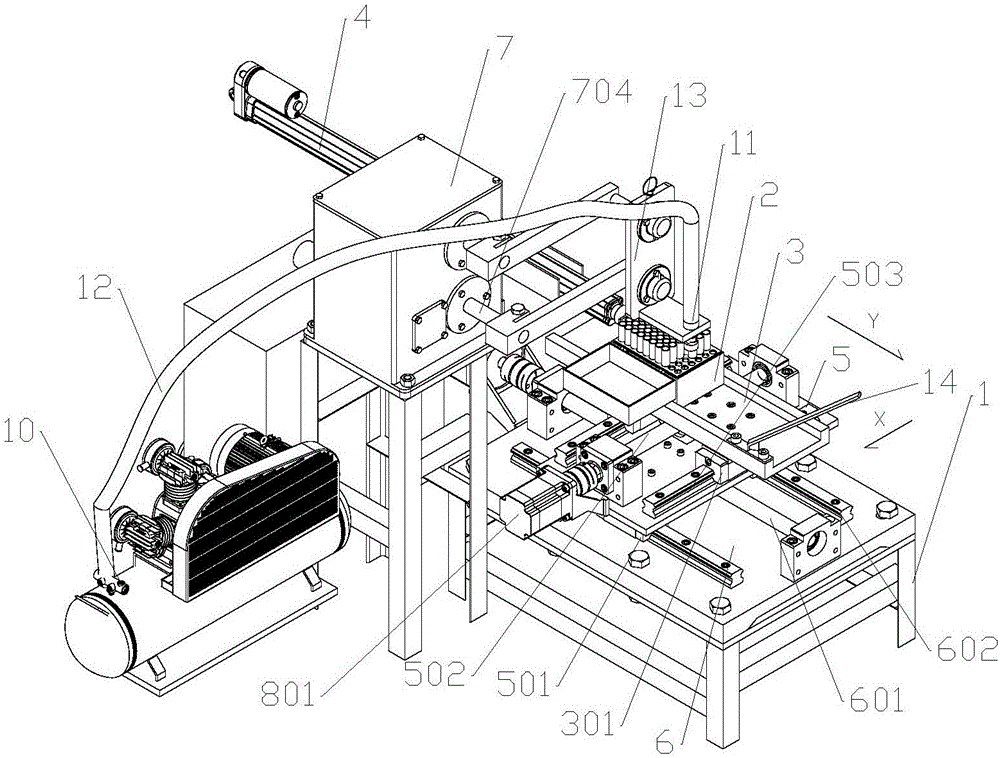

[0027] Such as figure 1 As shown, the pipette tip box packing system includes a rack 1, a box packing mechanism arranged on the rack 1, and a transport mechanism for transporting pipette tips. The purchased pipette tips are transported one by one by the transport mechanism.

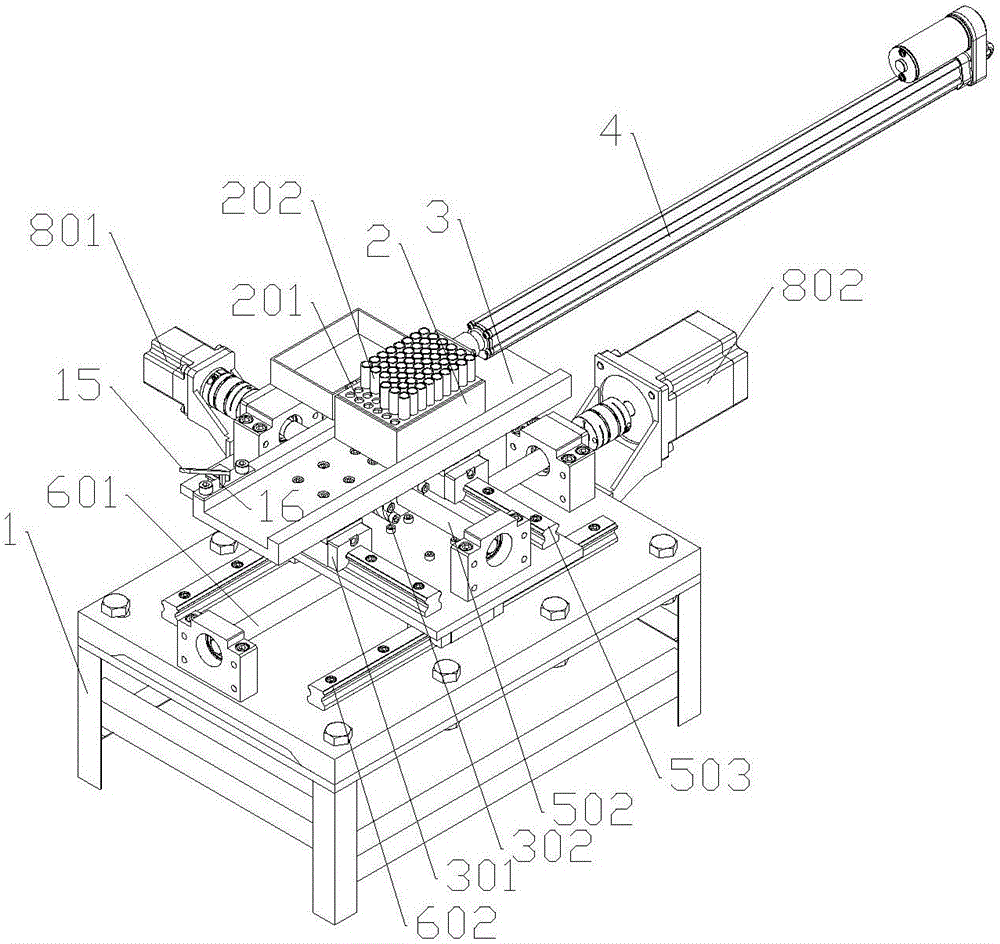

[0028] The box loading mechanism includes a tip-taking mechanism for taking tips from the conveying mechanism, a tip box platform 3 for placing the tip box 2, and an electric motor for pushing the tip box 2 to move on the tip box platform 3. The push rod 4 is a horizontal workbench for carrying the tip box platform 3 and driving the tip box platform 3 to move along two mutually perpendicular directions.

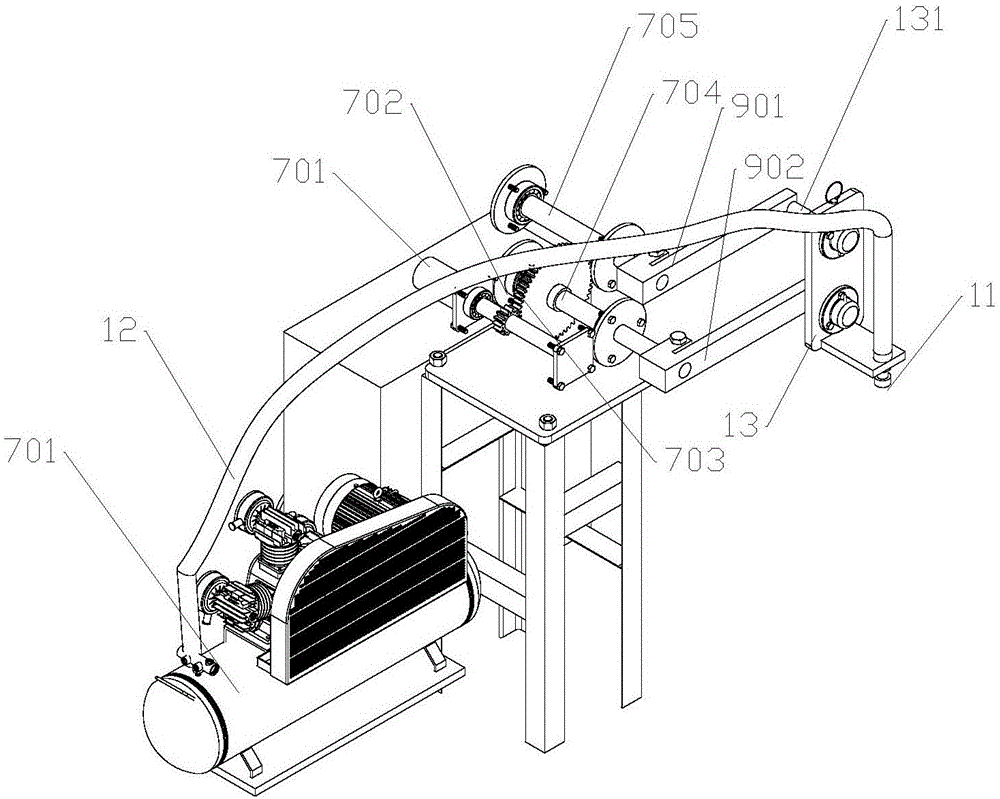

[0029] The gun tip taking mechanism includes a gun tip acquisition device and a control mechanism 7 that can control the movement of the gun tip acquisition device betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com