Image feedback multi-MEMS device piezoelectric automatic pick-and-place robot and control method thereof

A robot and device technology, applied in image communication, color TV parts, TV system parts and other directions, can solve the problems of time-consuming and labor-intensive cost, easy damage, poor pick-and-place effect, etc., to improve the pick-and-place accuracy , reduce uncertainty and improve pick and place efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

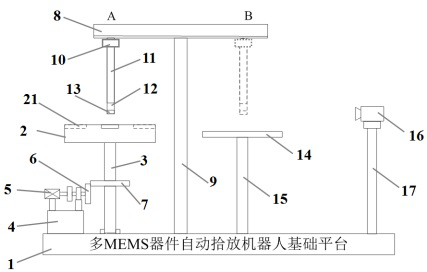

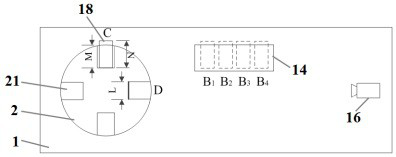

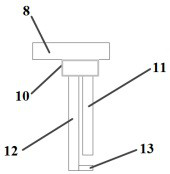

[0042] A piezoelectric automatic pick-and-place robot for multiple MEMS devices with image feedback, such as Figures 1 to 3 As shown, it includes a basic platform 1, on which a circumferential rotation unit, an automatic pick-and-place device, a piezoelectric adjustable sample stage and a liftable image detection unit are sequentially fixed from left to right; the circumferential rotation unit is provided with a circle The MEMS device 18 is placed on the circular platform 2; the automatic pick-and-place device is provided with a movable clamping structure, and the clamping structure is used to clamp and transfer the MEMS device 18 on the circular platform 2 to the pressure Electrically adjustable sample stage; the liftable image detection unit is located in the center position on the right side of the circumferential rotation unit, and the liftable image detection unit is used for real-time image detection of the piezoelectric adjustable sample stage, circumferential rotation ...

Embodiment 2

[0054] Using the piezoelectric automatic pick-and-place robot for multiple MEMS devices provided in Example 1 to perform automatic pick-and-place control methods for multiple MEMS devices, such as Figures 4 to 5 shown, including the following steps:

[0055] (1) Height initialization of the liftable image detection unit: control the extension and retraction of the first piezoelectric telescopic rod 17 and adjust the height of the camera device 16 so that the horizontal line of the center of the field of view of the camera device 16 is at the same level as the upper surface of the circular platform 2 .

[0056] (2) Initialization of the height of the piezoelectric adjustable sample stage: control the expansion and contraction of the second piezoelectric telescopic rod 15, detect the height change information of the upper end face of the sample stage 14 in real time through the camera device 16, and adjust the telescopic length of the second piezoelectric telescopic rod 15 until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com