PCB plate handling robot capable of taking and placing materials accurately

A technology for handling robots and PCB boards, applied in the field of robots, can solve the problems of difficulty in improving the cutting efficiency of PCB boards and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

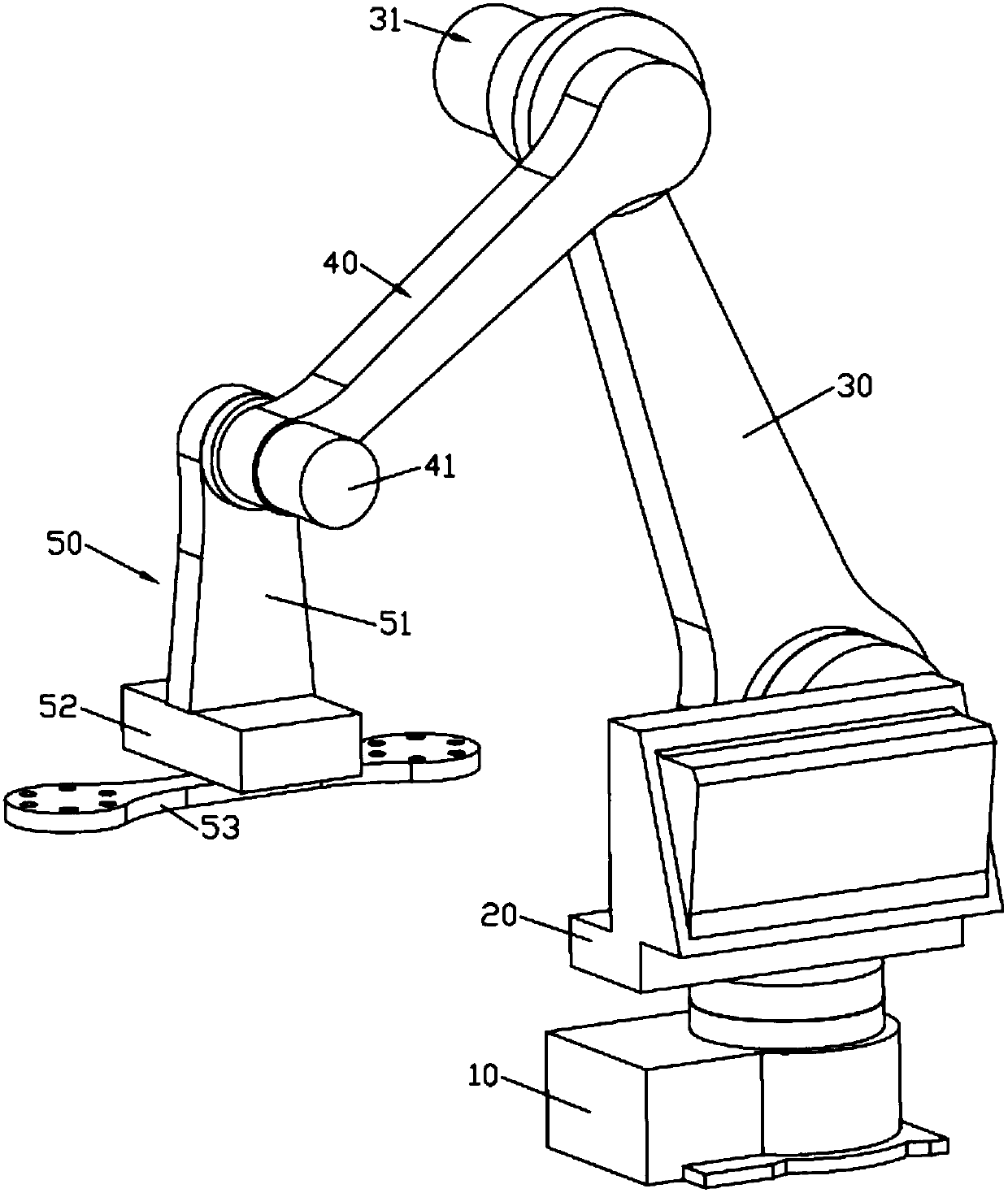

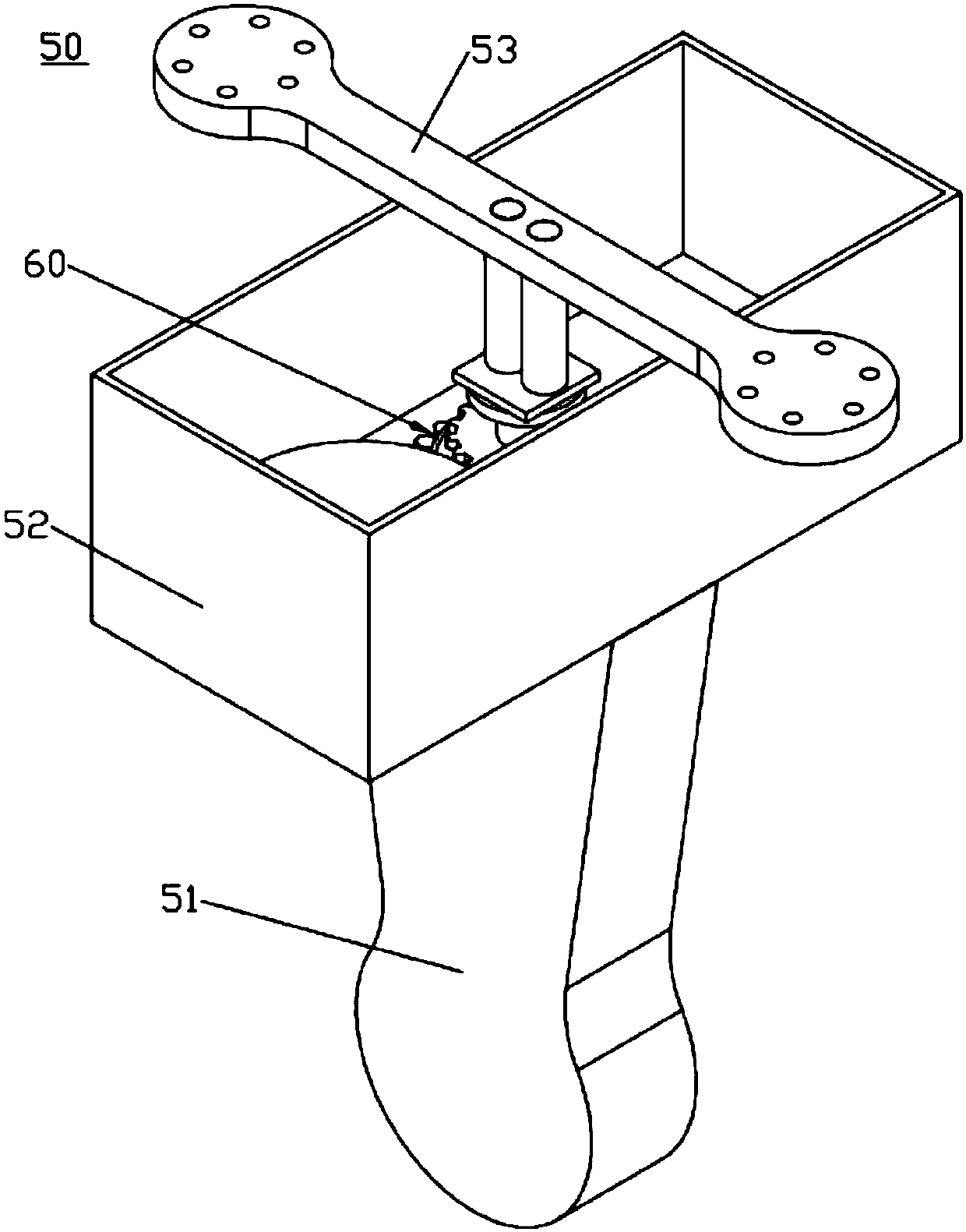

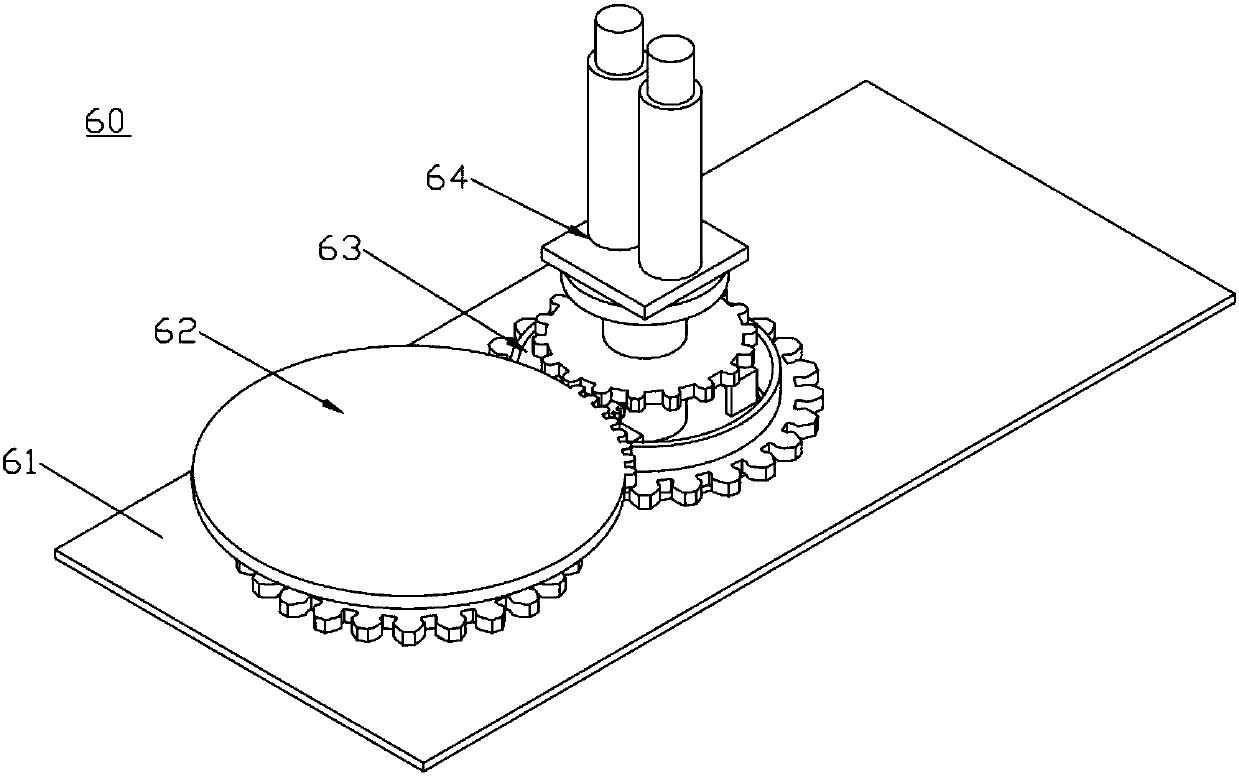

[0019] like Figure 1 to Figure 7 As shown, a PCB board handling robot that can accurately pick and place materials includes a base body 10, a waist swivel part 20 pivotally connected to the base body 10, a large arm 30 pivotally connected to the waist swivel part 20, and a The small arm 40 on the big arm 30, the manipulator 50 installed on the small arm 40; the manipulator 50 includes a pair of sucker groups, and a drive mechanism 60 that drives the pair of sucker groups to rotate; the drive mechanism 60 includes a base 61, Rotation drive device 62, lock assembly 63 and rotation assembly 64; Rotation assembly 64 includes a pair of positioning rods 641, rotation support 642 and first gear 643; Rotation support 642 upper end is fixed with a pair of positioning rods 641, middle part is fixed with the first gear 643; A gear 643, the lower end of which is pivotally connected to the base 61; the first gear 643 has a limit hole 6431; the lock assembly 63 includes an unlocking compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com