Automatic loading and unloading mechanism of hydraulic machine

A technology of automatic loading and unloading, hydraulic press, applied in the direction of presses, manufacturing tools, etc., to achieve the effect of saving workload, saving time for machine adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

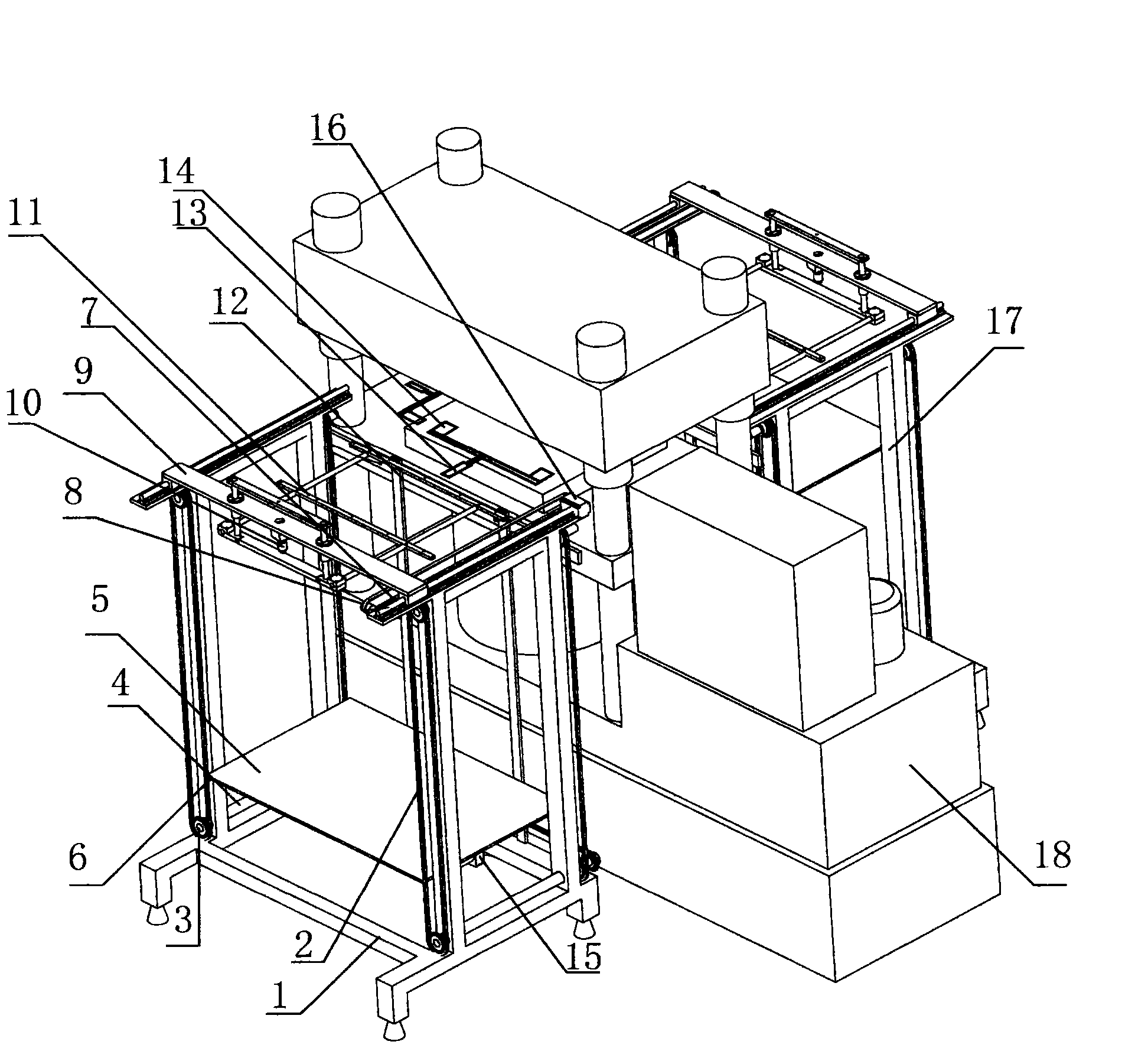

[0011] Such as figure 1 As shown, the automatic loading and unloading mechanism of the hydraulic machine described in the embodiment of the present invention includes a feed frame 1, an upper and lower cylinder 10, a suction plate 12, a positive feed cylinder 13, a stepping motor 16 and a discharge frame 17. The feed frame 1 and the discharge frame 17 are respectively arranged on both sides of the hydraulic press 18 and have the same main structure. The upper and lower cylinders 10 are installed on the top of the feed frame 1, and the lifting bracket of the feed frame 1 is vertically arranged. The lifting material plate chain 2 and the gear 3 meshed with each other, the rear end shaft of the gear 3 is connected to the gear shaft bar 4, and the supporting plate 5 is arranged in the middle of the frame body in parallel through the connecting pin 6, and the lower end of the supporting plate 5 is provided with Gear motor 15; the upper side of the upper and lower cylinders 10 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com