Novel cover pressing mechanism

A new type of capping technology, applied in the direction of conveyors, flanged bottle caps, conveyor objects, etc., can solve the problems of low packaging efficiency and low degree of automation, and achieve compact structure, high level of automation, and accurate pressing high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

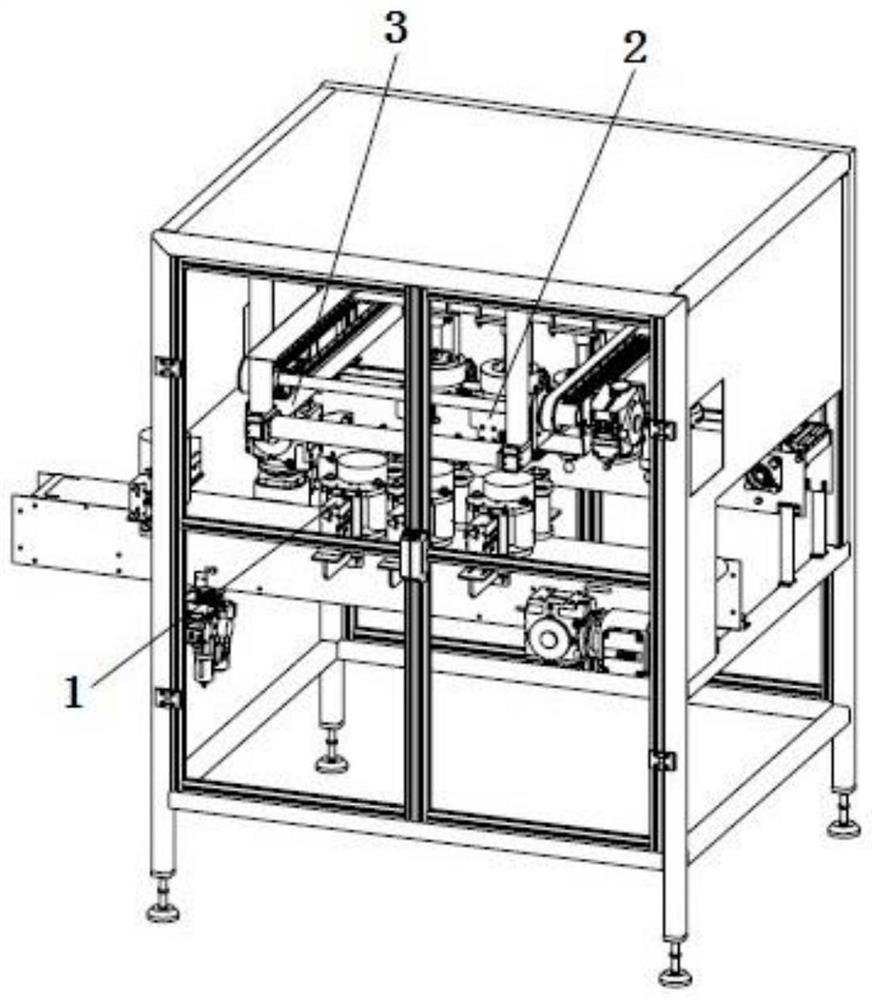

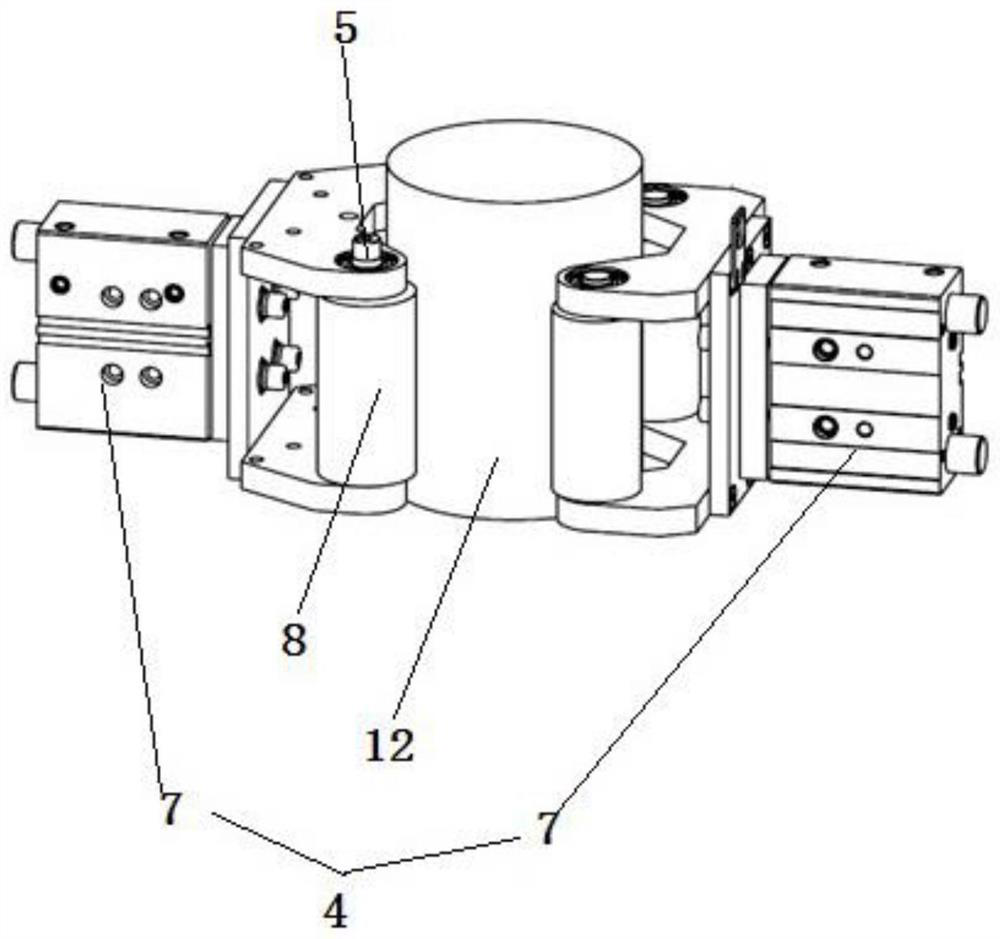

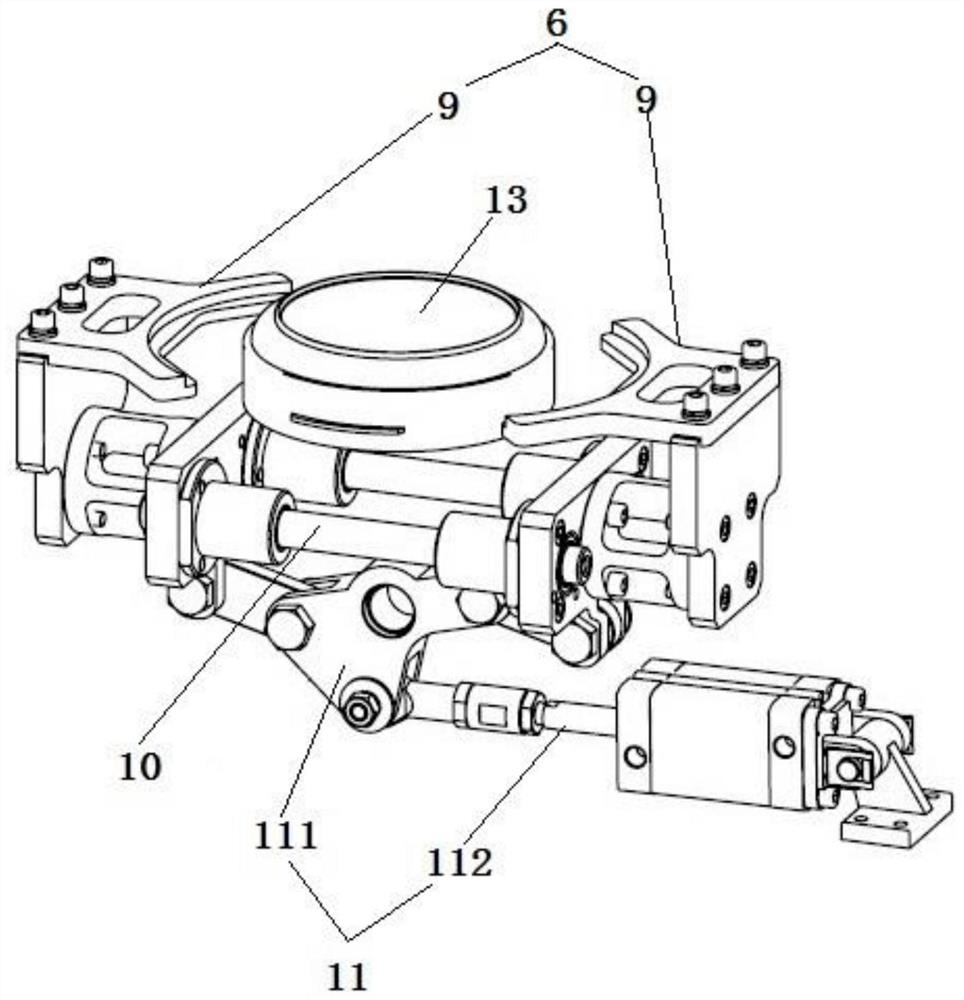

[0021] Such as Figure 1 to Figure 4 As shown, a new type of capping mechanism includes a can conveying assembly 1, a cap conveying assembly 2 and a capping assembly 3, and the can conveying assembly 1 includes a first color mark sensor, a can holding part 4 and an element for driving a can 12 The can rotating part 5 rotates in position, the cap conveying assembly 2 includes a conveyor belt, the second color mark sensor and the cap holding part 6 that clamps the cap 13 in the horizontal direction, and the capping assembly 3 includes a capping cylinder 31 and a cap suction head 32. The upper end of the cap suction head 32 is connected to the cap gland cylinder 31, the lower end of the cap suction head 32 is used to absorb the cap 13, the tank holding part 4 is located below the cap holding part 6, and the push rod of the cap gland cylinder 31 mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com