Automatic measurement method for data of stacking machine

An automatic measurement and stacker technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of stacker walking deviation and the difficulty of accurate installation of photoelectric detectors, etc., and achieve the effect of accurate pick-and-place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The automatic data measurement method of the stacker of the present invention is used to obtain the accurate position value of the stacker walking in the automatic three-dimensional warehouse.

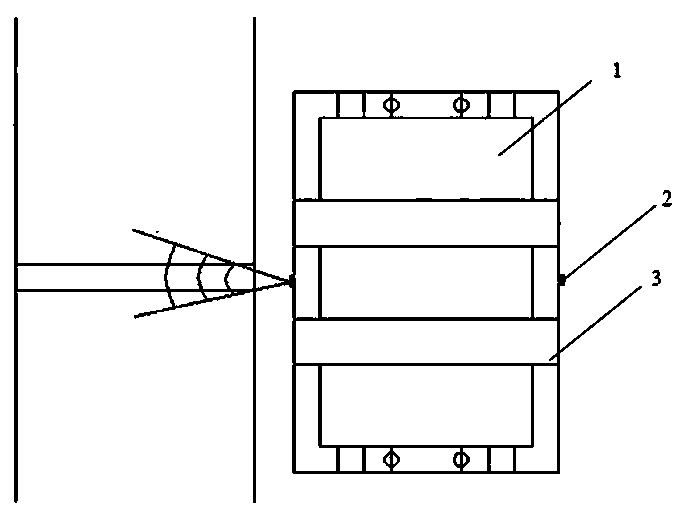

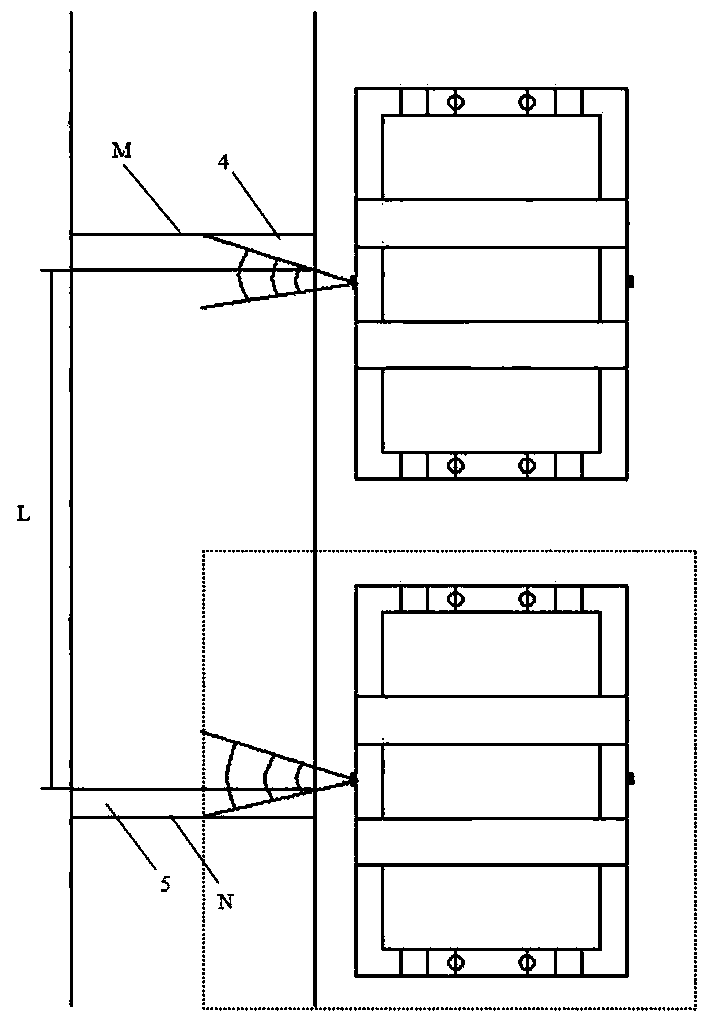

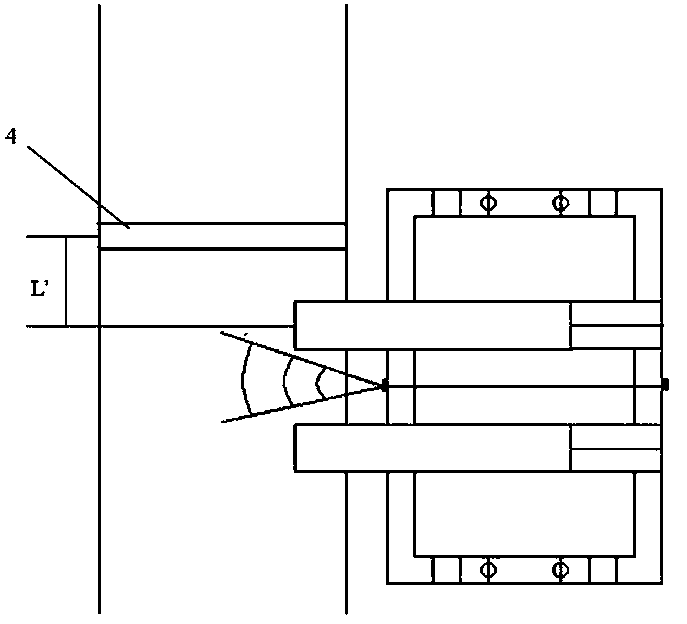

[0016] ginseng figure 1 , the automatic data measurement method of the stacker of the present invention is used to obtain the accurate position value of the stacker walking in the automatic three-dimensional warehouse. The stacker includes a frame, a cargo platform 1 located on the frame, a cargo detection photoelectric 2 located on the cargo platform, and cargo forks 3 located on both sides of the cargo detection photoelectric 2. The stacker is also connected with a electrical control system. The automated three-dimensional warehouse has a first column 4 and a second column 5, and a beam 7 is provided between the first column 4 and the second column 5, and the beam 7 is provided with pallets 6 equidistantly distributed, and the width of the pallet 6 is known . The method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com