Moving device of tube gripper of spinning machine

A technology of mobile device and pipe grabber, which is applied in the direction of textiles and papermaking. It can solve the problems of not meeting the needs of the production site of the textile factory, occupying a large space, and difficult to move, so as to achieve small space occupation, avoid bending, and grasp and release pipes. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

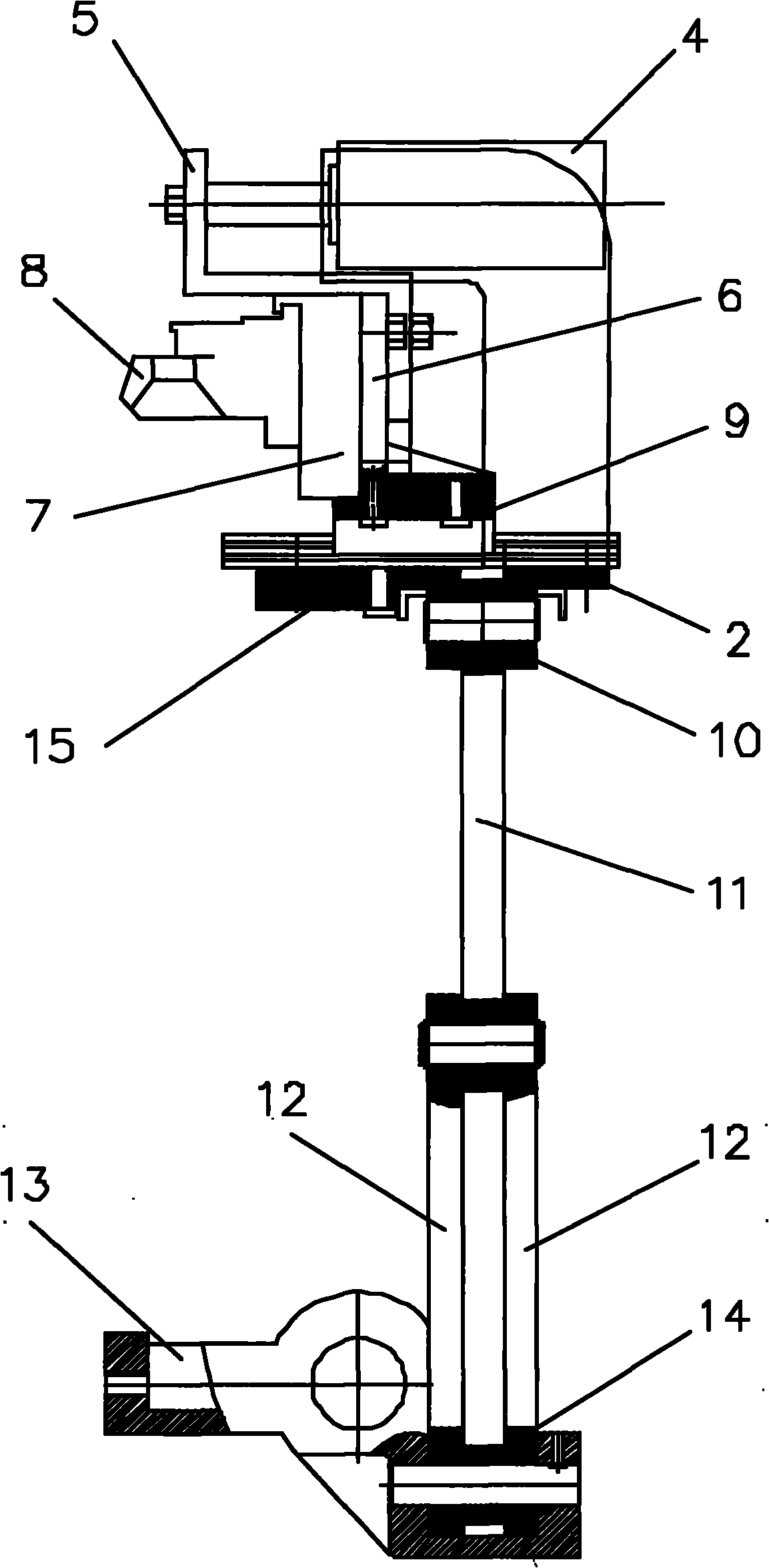

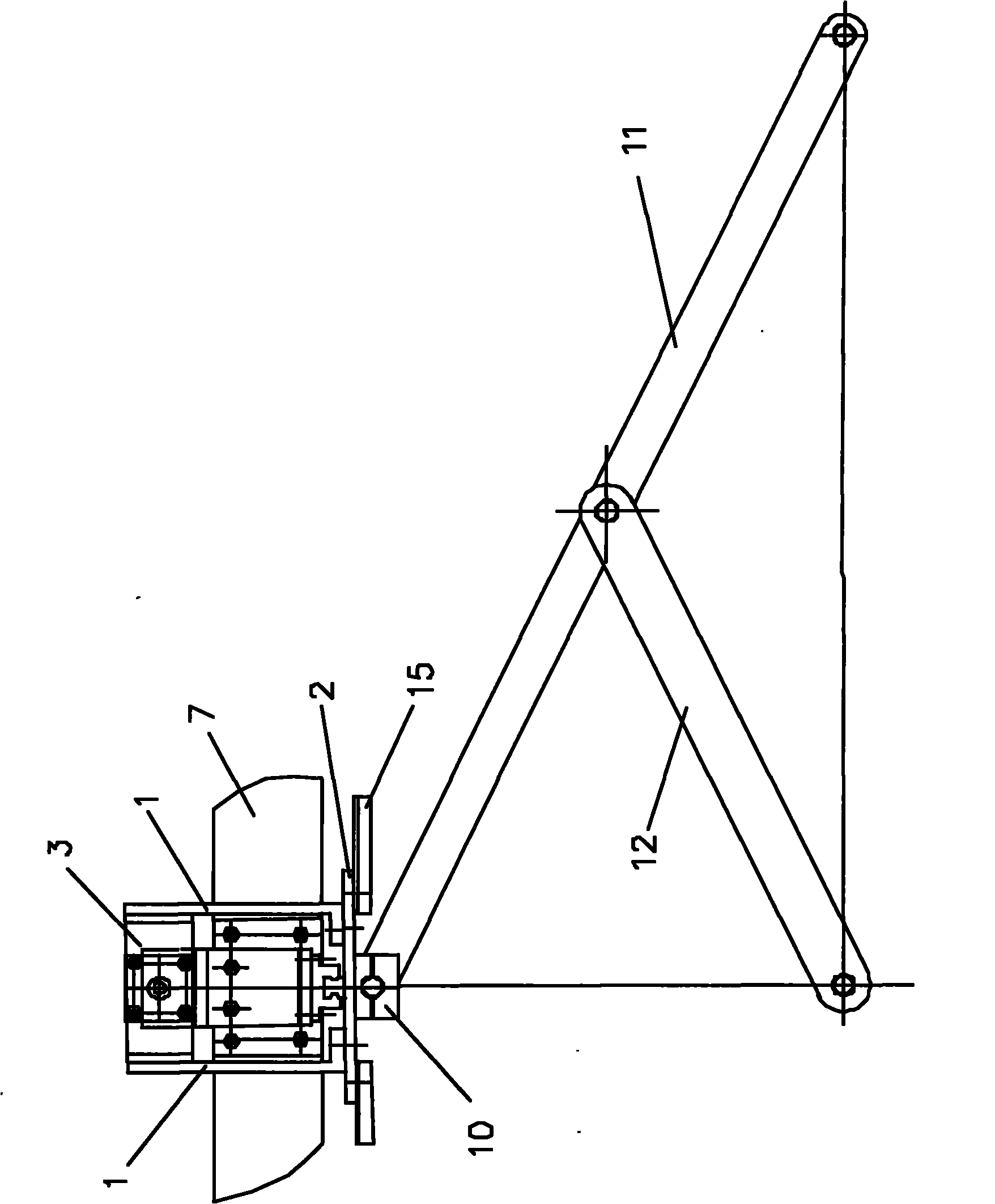

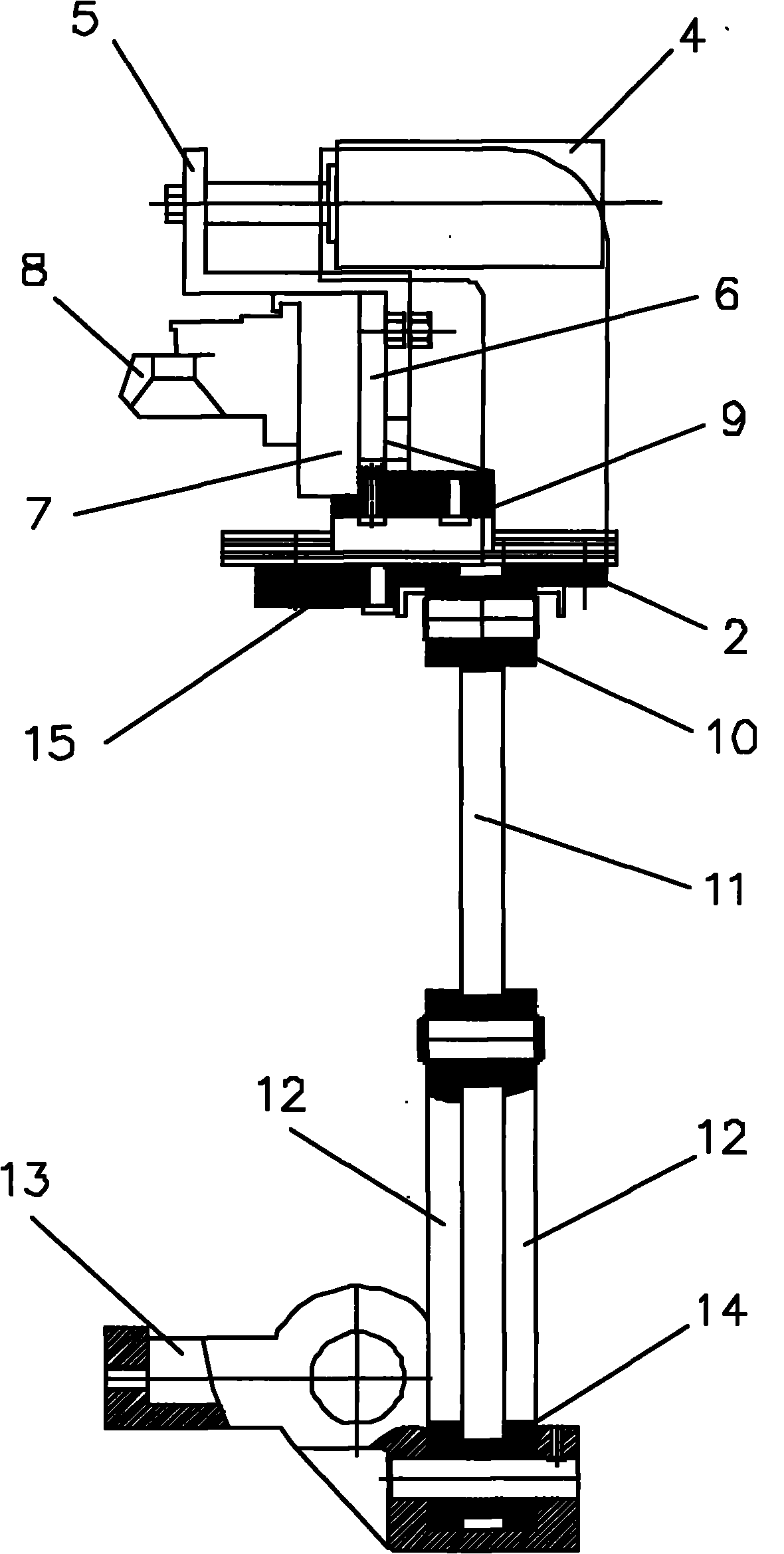

[0013] Such as figure 1 and figure 2 As shown, a moving device of a yarn spinning machine gripper of the present invention includes a vertical plate 1, a support plate 2, a cylinder seat 3, a cylinder 4, a push plate 5, an aluminum tube seat 6, a yarn gripper 7, and a gripper Device 8, rolling linear guide pair 9, bearing 10, long connecting rod 11, short connecting rod 12 and hanging pin 13. Riser 1 is two pieces, can be L-shaped. The two vertical plates 1 are arranged above the support plate 2 in correspondence with each other, the cylinder base 3 is fixedly connected to the two vertical plates 1 , and the cylinder base 3 is fixedly connected to the cylinder 4 . The connecting rod in the cylinder 4 is fixedly connected with one end of the push plate 5, the other end of the push plate 5 is fixedly connected with one side of the aluminum tube base 6, and the other side of the aluminum tube base 6 is fixedly connected with one side of the yarn holder 7, The other side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com