Circulating supply device used for motor rotor iron core

A technology of feeding device and motor rotor, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to achieve low-cost and high-efficiency switching and transportation, cumbersome supporting control devices, complex structure, etc., to ensure continuity And stability, control and method are simple, avoid mutual interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and a detailed implementation mode and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

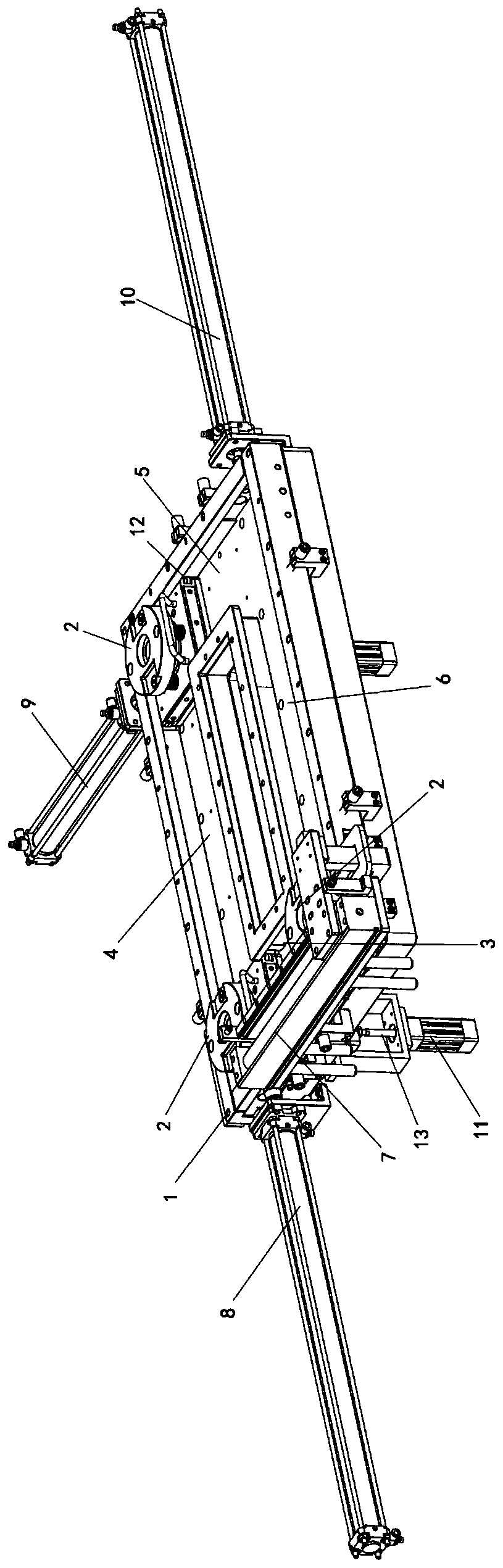

[0023] Such as figure 1 As shown, this embodiment provides a circulating feeding device for a rotor core of a motor, which includes a platform 1, a tray 2 and a plurality of cylinders. The platform 1 is provided with end-to-end polygonal moving grooves. The pallet 2 slides cyclically in the moving groove, and the iron core is installed on the pallet 2. The moving trough is divided into multiple chutes according to the number of sides of the polygon. Each cylinder is installed on a section of chute to push or pull the pallet 2 in the section of chute to move. The connection of the two sections o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com