Thickener underflow concentration, mud layer height, soft measuring device and method for internal ore quantity

A technology of thickener and soft measurement, which is applied in the field of dressing and smelting, can solve the problems of lack of thickener operating status, difficulty in detecting thickener mud layer height, internal ore quantity, and inability to accurately understand thickener operating status, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

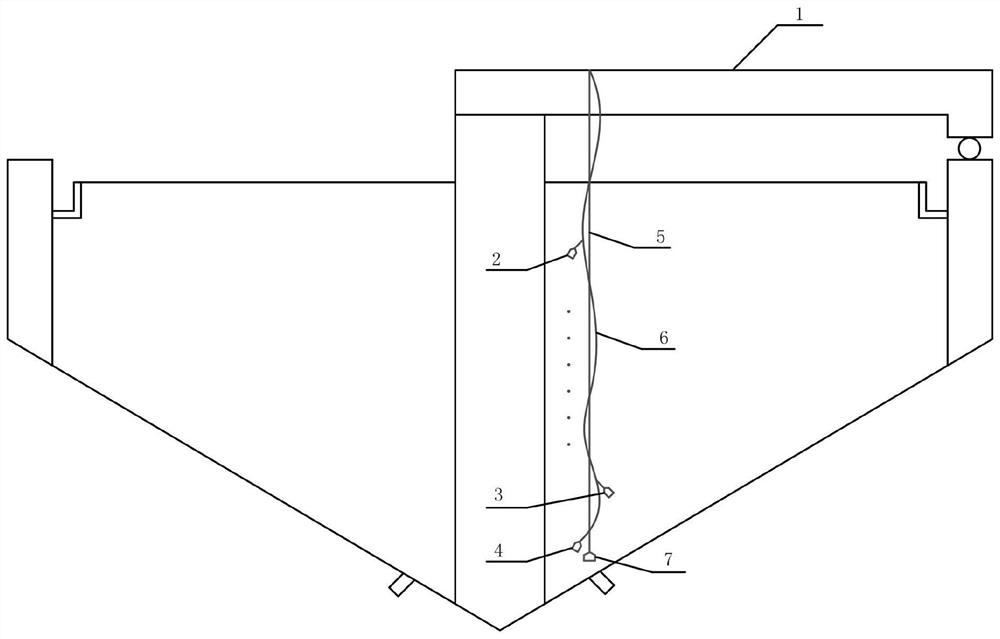

[0063] According to the accompanying drawings, the thickener underflow concentration, mud layer height, internal ore quantity soft measuring device and method are described in detail:

[0064] 1. The thickener underflow concentration, mud layer height, and internal ore quantity soft measuring device, such as figure 1 As shown, including N pressure sensors (2) (3) (4), cables (6), steel cables (5), and counterweights (7);

[0065] N pressure sensors (2) (3) (4) are all connected to the cable (6), the cable (6) is fixed on the steel cable (5), and one end of the steel cable (5) is fixed on the thickener walking frame (1) and the other end is connected with counterweight (7);

[0066] N pressure sensors (2) (3) (4) are used to measure the pressure of the pulp to be tested at different heights in the thickener, the number of pressure sensors is N≥3, and the first pressure sensor (2) is on the moisture interface of the pulp to be tested , the Nth pressure sensor (4) is located at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com