Positioning transfer jig

A fixture and transfer technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of glass surface wear, low operating efficiency, and affecting the appearance of glass, and achieve the effect of accurate pick and place and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

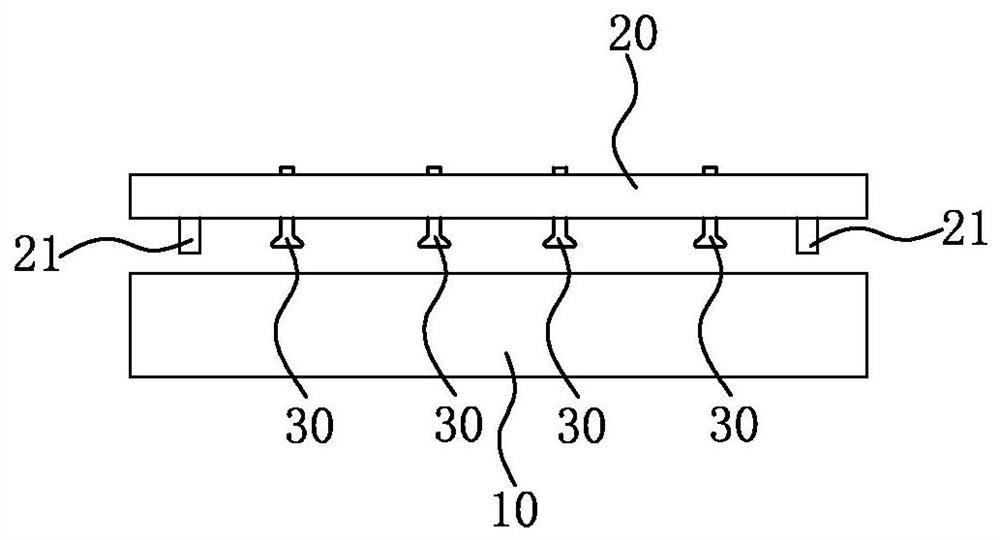

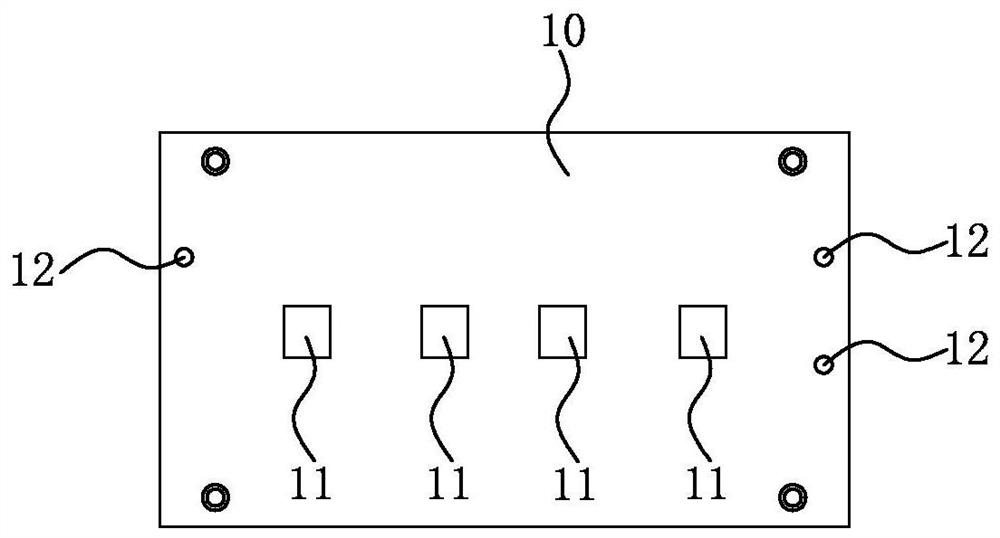

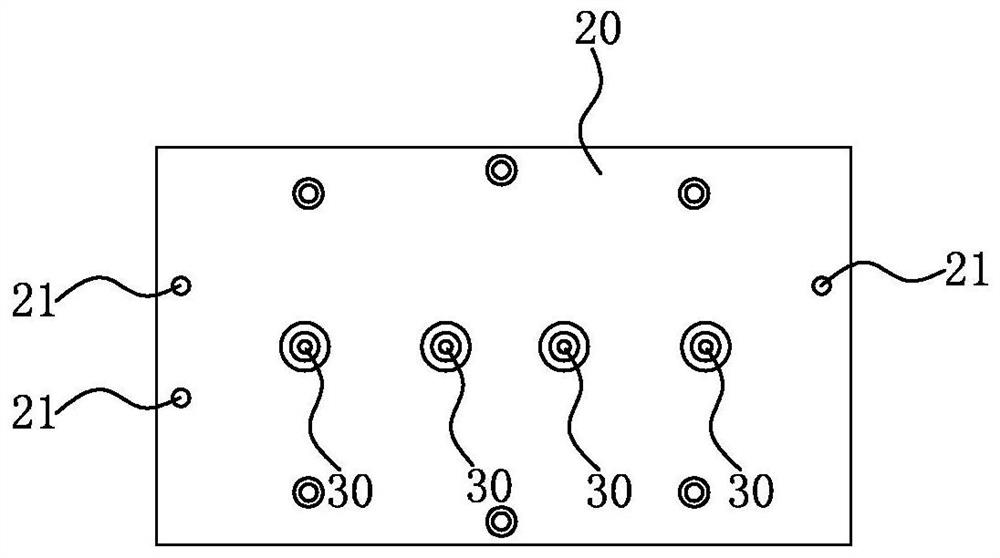

[0024] Such as Figure 1-3 As shown, a positioning transfer jig is used to pick and place workpieces in cooperation with a mechanical arm; the positioning transfer jig includes a base 10 , a connecting plate 20 and at least one set of soft suction cups 30 . Wherein, the top surface of the base 10 is provided with at least one profiling positioning groove 11; the connecting plate 20 is arranged on the top of the base 10, and is connected with the mechanical arm; the soft sucker 30 is connected to the bottom of the connecting plate 20, and a set of soft The soft suction cups 30 correspond to one profiling positioning groove 11; each group includes at least one soft suction cup 30; each soft suction cup 30 is connected with a vacuuming device.

[0025] Specifically, in the positioning and transferring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com