Environment-friendly multifunctional porous roll paper production method and its device

A manufacturing method and roll paper technology, applied in the field of papermaking, can solve the problems of reducing the fiber adhesion of raw materials, the inability to achieve stable product quality, and the strong permeability of adhesives, so as to improve the level of national health care and prevent national The outflow of wealth and the effect of moving customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

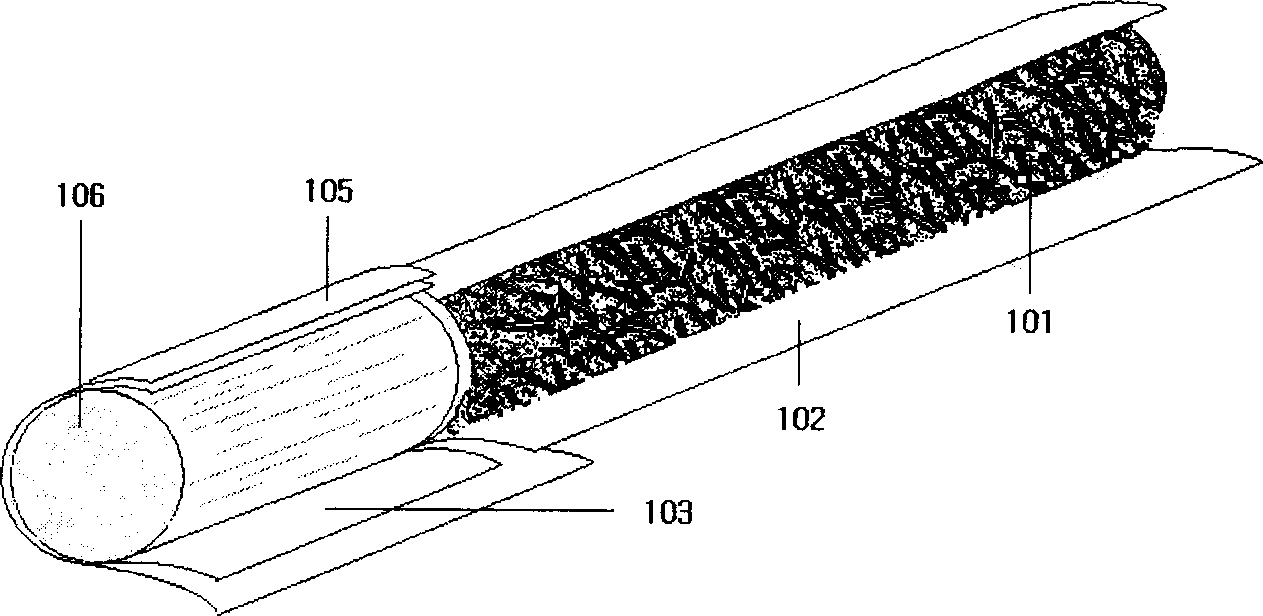

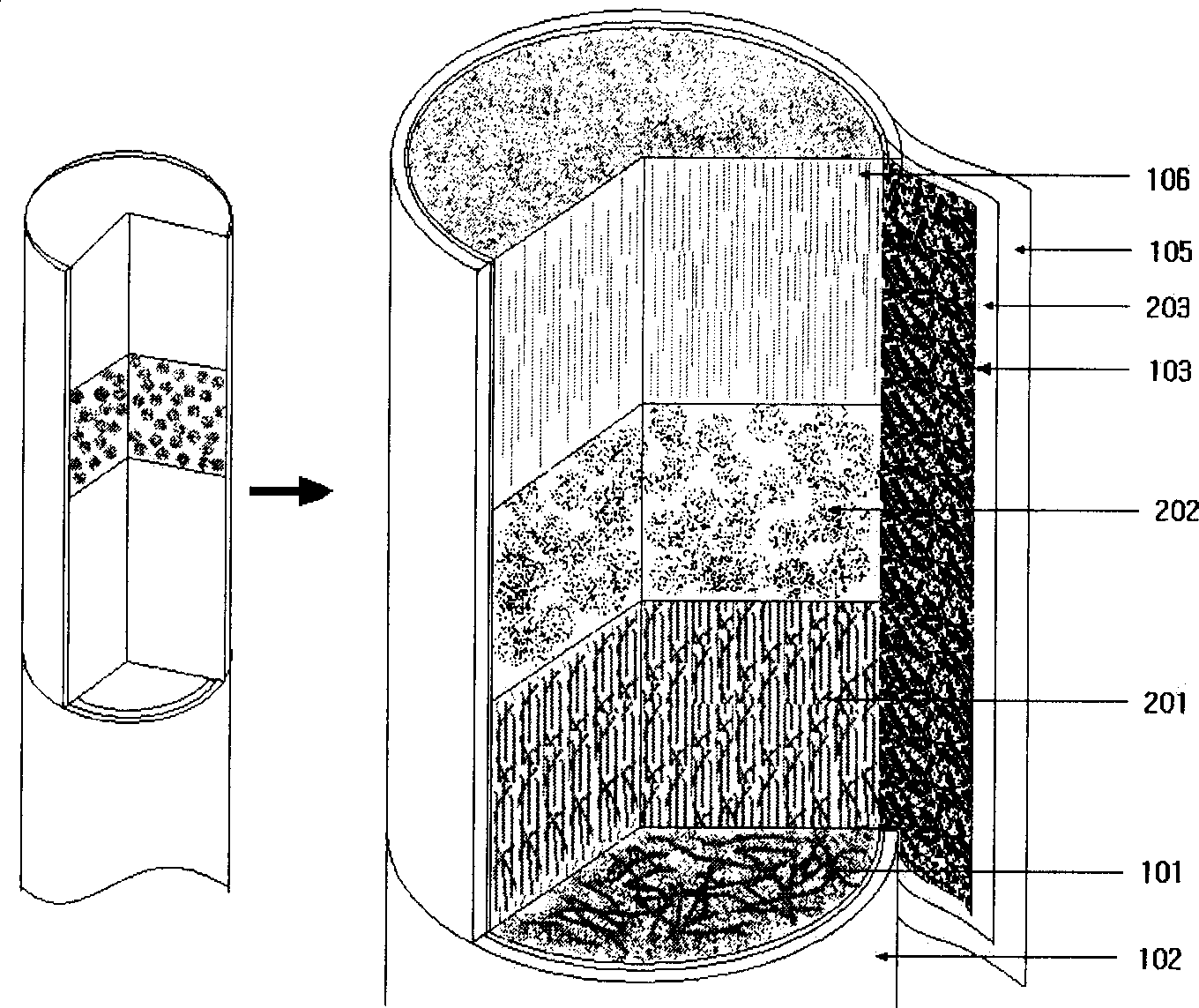

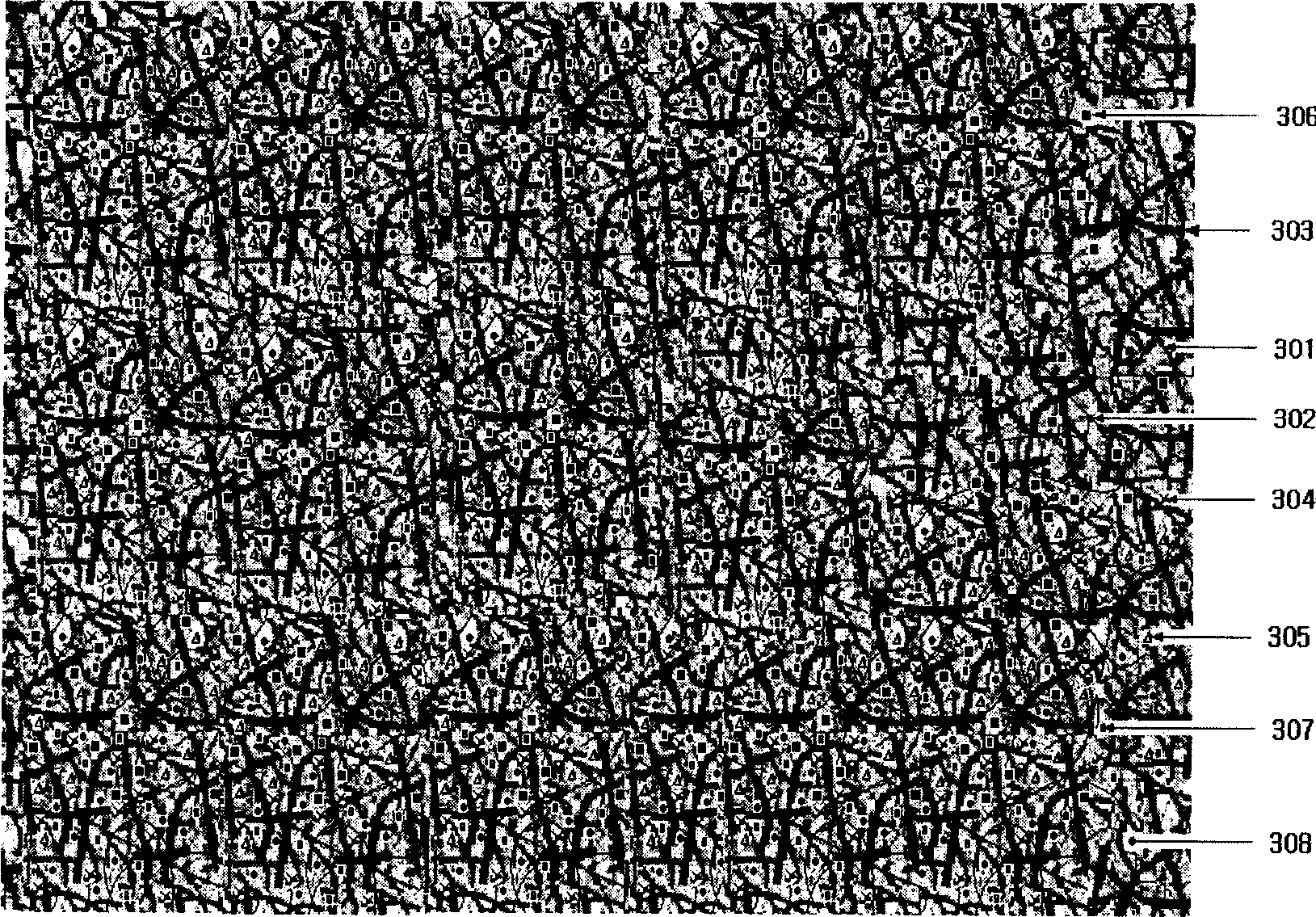

[0062] The composition and manufacturing process of the environment-friendly multifunctional porous roll paper of the present invention will be further described in detail below with reference to the accompanying drawings.

[0063] The main raw materials of the environment-friendly multifunctional porous roll paper of the present invention are natural pulp or chemical pulp (301), rayon (302), activated carbon superfine wire (303) and chemical additive VPB (304), polyvinyl alcohol ( PVA) (307), SPG (308), AmtiPick (306), etc., and diluted auxiliary raw materials (305) are epoxy resin, release agent, starch, etc. (refer to Table 2).

[0064] product name

(porosity)

Composition ratio (weight%)

pulp

Rayon

carbon filament

VPB

PVA

SPG

Amti Pick

epoxy resin

stripping agent

T-6000

88~92

3~4

2~4

2~3

0.2~0.3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com