Taking device used in contact riveting process

A technology of retrieving devices and contacts, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, low degree of automation, high labor cost, etc., and achieve low efficiency, high degree of automation, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

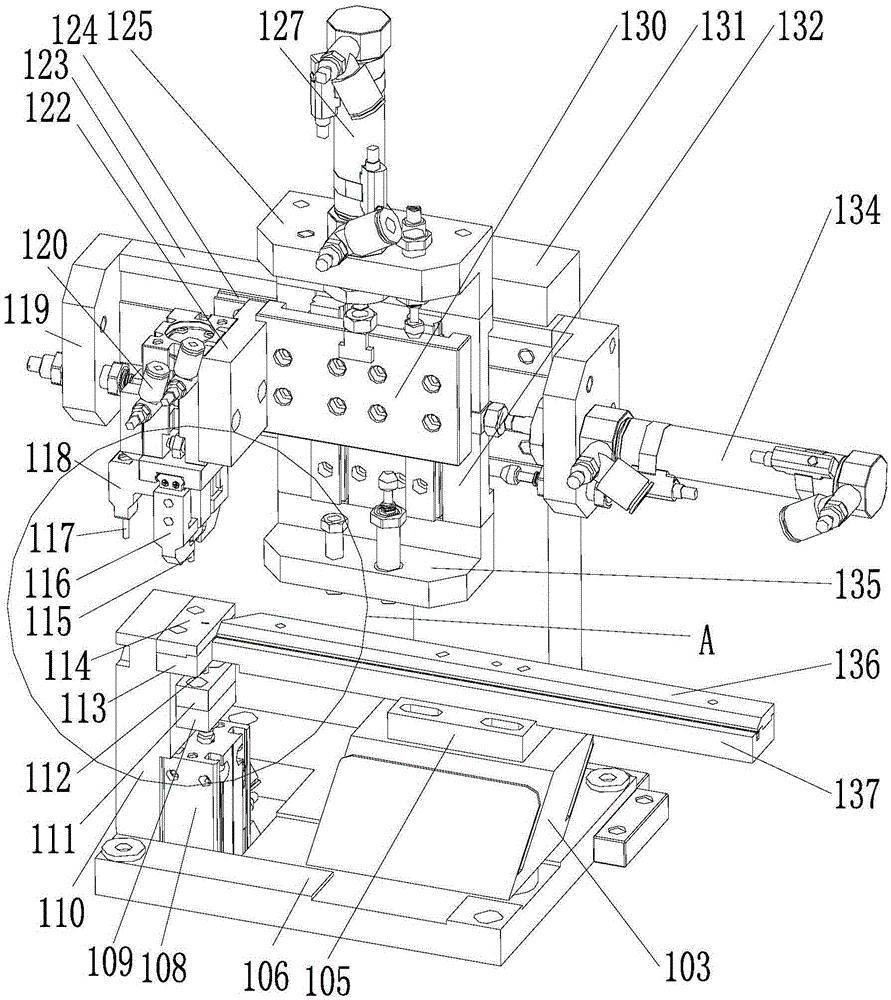

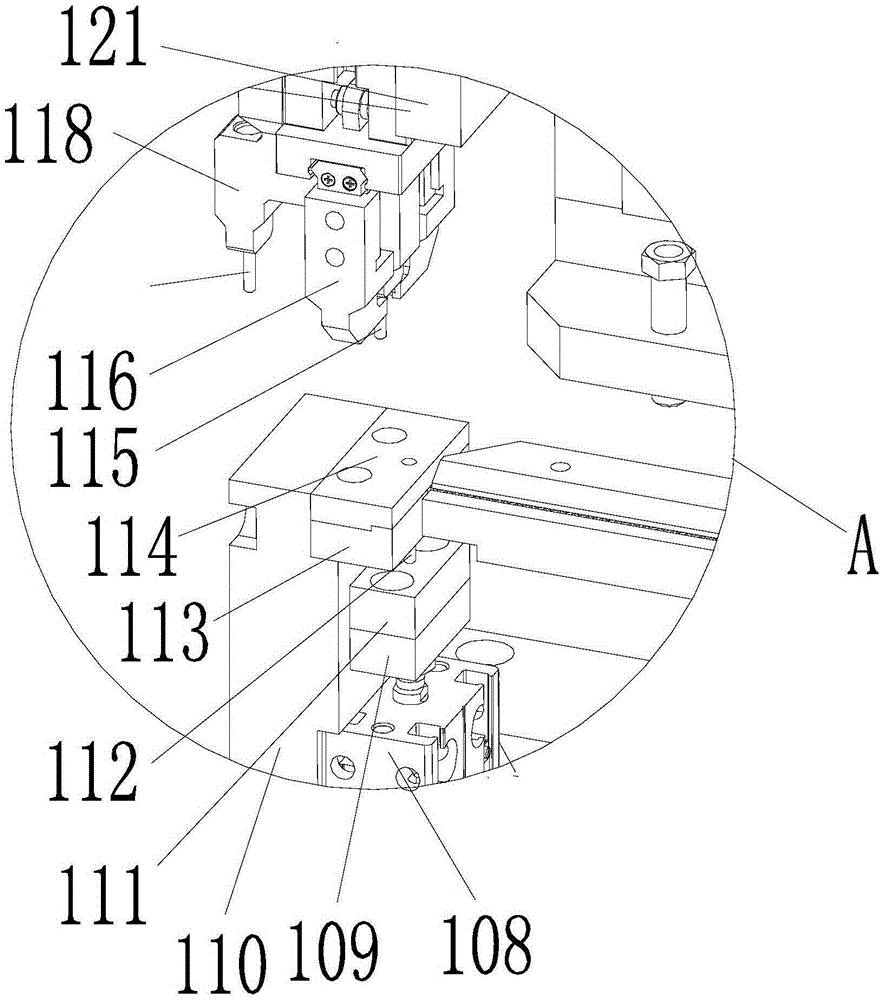

[0017] Examples such as figure 1 , figure 2 The shown one is used in the pick-up device used in the contact riveting process, including a bracket structure, a transverse channel 137 installed on the bracket structure, and the top of the transverse channel 137 is provided with an apex channel plate 113 adapted to it , the terminal is connected with a material vibrating plate; the apex material channel cover plate 114 is arranged above the apex material channel plate 113, and the apex material channel cover plate 114 is provided with a material channel hole matching the contact point. Below the apex material channel plate 113 is provided with an upper thimble 112 that is adapted to move up and down, and an upper cylinder 108 that is compatible with the upper thimble 112 is installed on the support structure; A lifting installation support 132 that can move left and right and a translation cylinder 134 for pushing and pulling the lifting installation support 132 are provided; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com