Omnidirectional moving transfer robot with Mecanum wheels

A handling robot, omnidirectional movement technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of difficult to deal with the working environment, less freedom of the actuator, low movement flexibility, etc., to improve the movement flexibility, ensure control accuracy, Overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

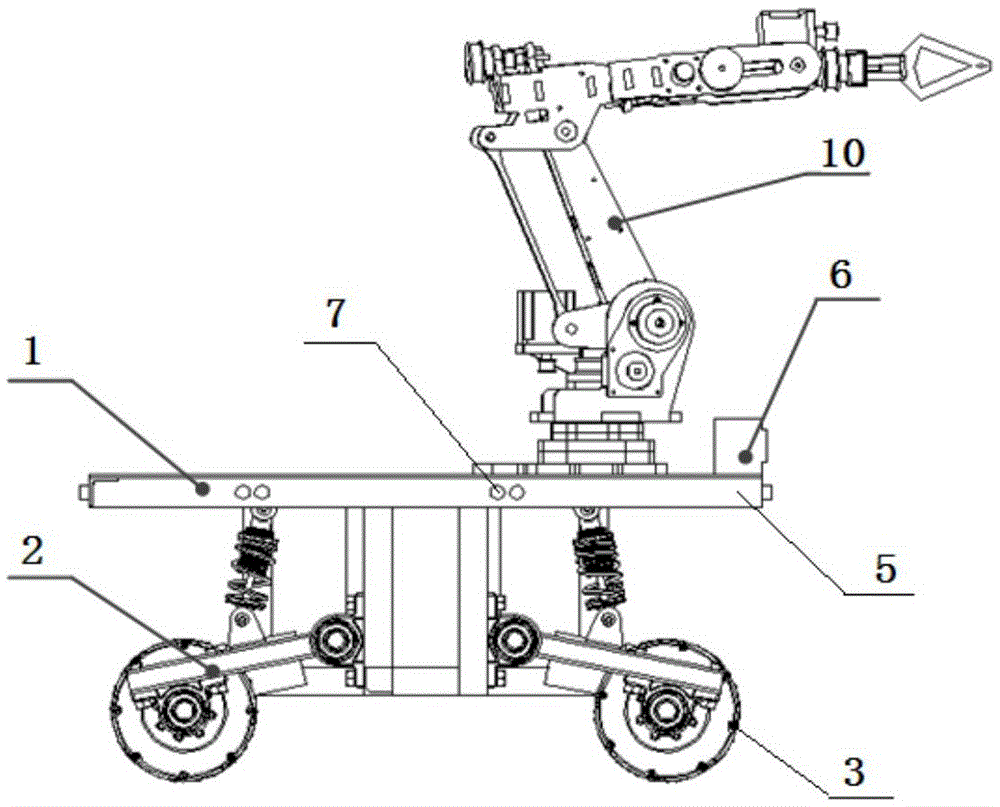

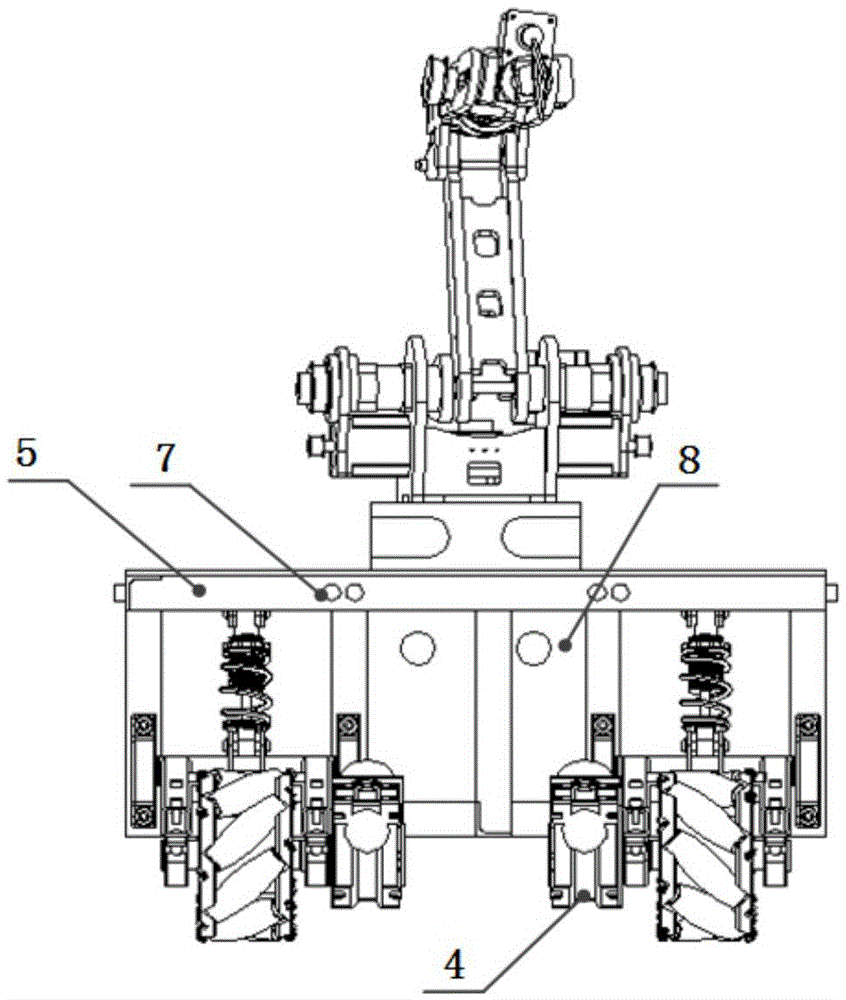

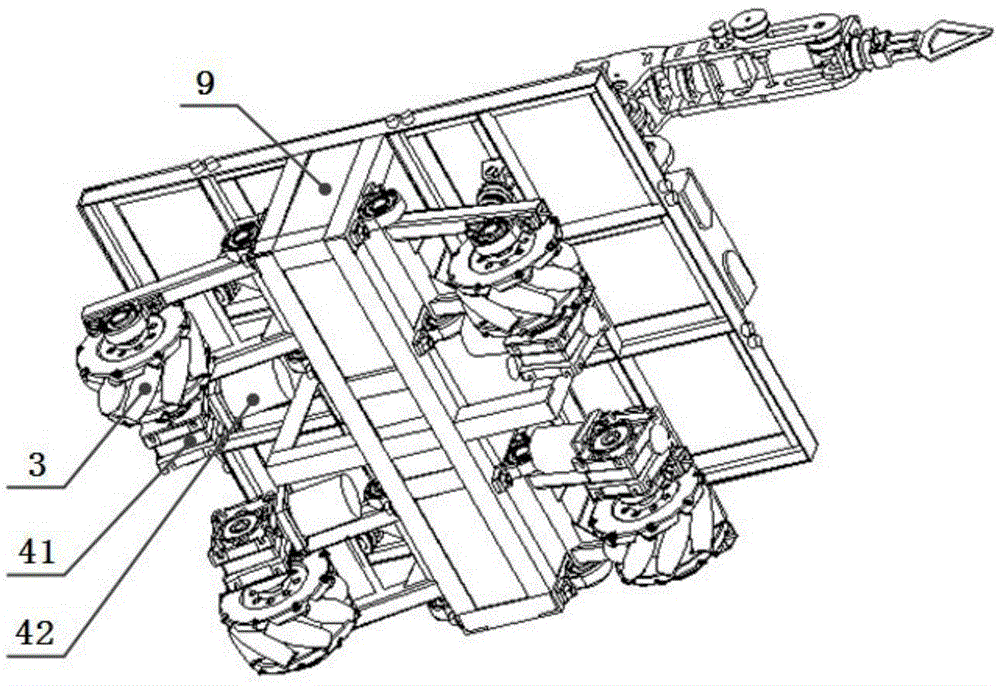

[0049] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a mecanum wheel omnidirectional mobile handling robot includes a six-degree-of-freedom manipulator 10, an omnidirectional mobile chassis 1, a binocular vision device 6, a main control box 8, a battery pack 9 and a remote monitoring device.

[0050] The omnidirectional mobile chassis 1 includes a frame 5 and several mecanum wheels 3 arranged under the frame 5 . The four mecanum wheels 3 are distributed at four corners under the frame 5 . The number of mecanum wheels 3 can also be set in multiples according to needs, all of which are also within the protection scope of the present invention.

[0051] The six-degree-of-freedom manipulator 10 is fixedly arranged on the top of the vehicle frame 5 ; the binocular vision device 6 is fixedly arranged on the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com