Method for preparing free layer of magnetic tunnel junction and method for preparing magnetic tunnel junction

A magnetic tunnel junction and free technology, which is applied in the manufacturing/processing of electromagnetic devices, can solve the problems of poor surface properties of the free layer, achieve the effects of improving TMR value, improving overall performance, and eliminating damage or defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

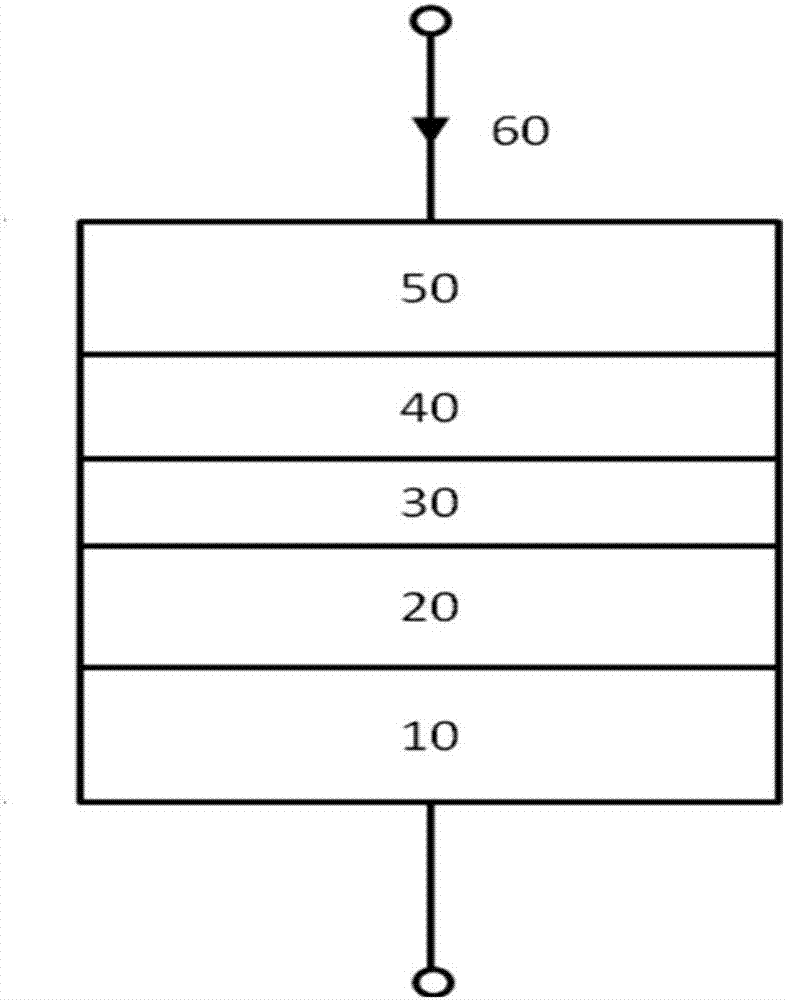

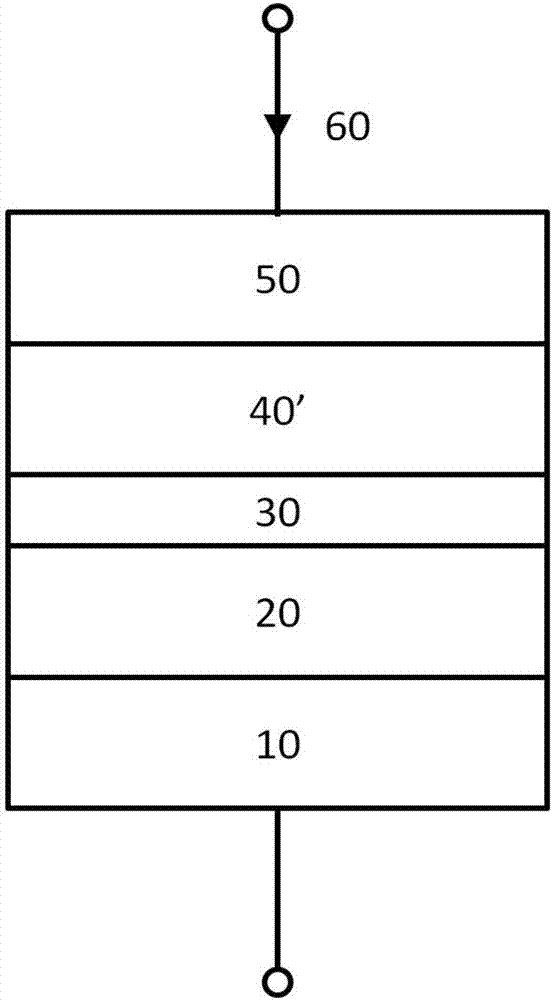

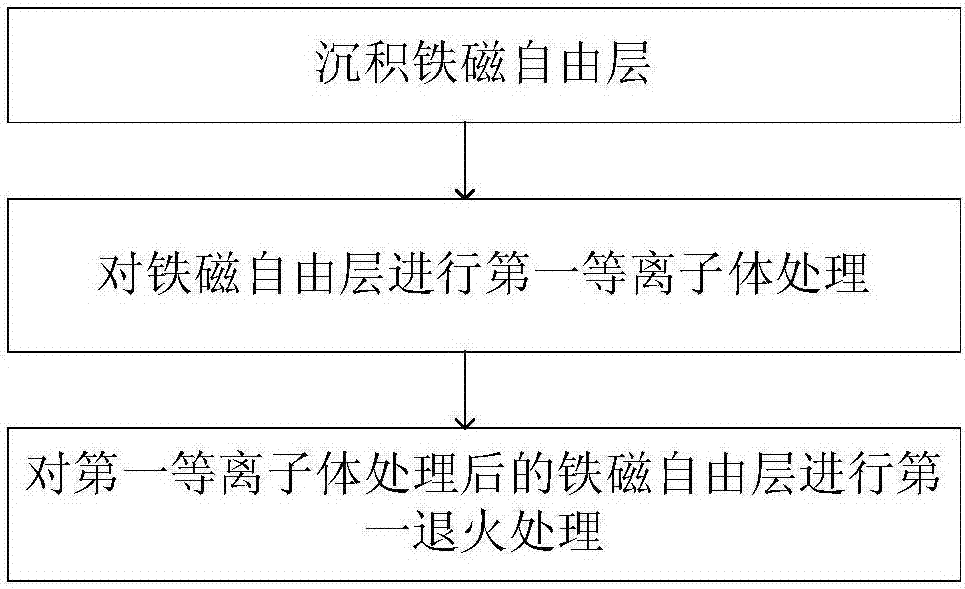

[0053] In the preferred embodiment A, such as figure 2 As shown, the above-mentioned film includes a ferromagnetic free layer 40', and the corresponding preparation method is as image 3 As shown, it includes: depositing a ferromagnetic free layer 40'; performing a first plasma treatment on the ferromagnetic free layer 40'; performing a first annealing treatment on the ferromagnetic free layer 40' after the first plasma treatment.

[0054] The material forming the ferromagnetic free layer 40' in the above embodiment A can be selected from Co, Fe, Ni, CoB, FeB, NiB, CoFe, NiFe, CoNi, CoFeNi, CoFeB, NiFeB, CoNiB, CoFeNiB, FePt, FePd, One or more combinations of CoPt, CoPd, CoFePt, CoFePd, FePtPd, CoPtPd, CoFePtPd. Preferably, the thickness is 0.4 nm to 3 nm. The plasma in the first plasma treatment can be Ar, Kr, Xe, He, N 2 , H 2 , Or O 2 One or more of the other gases are formed. The etching rate of the first plasma treatment is very low, preferably less than 0.02 nm / s. During...

Embodiment approach 1

[0059] Embodiment one: deposit a first ferromagnetic free layer 41; perform a first plasma treatment on the first ferromagnetic free layer 41, and perform a first annealing on the first ferromagnetic free layer 41 after the first plasma treatment Treatment; a non-magnetic metal insertion layer 42 is deposited on the first layer of ferromagnetic free layer 41 after the first annealing treatment; a second layer of ferromagnetic free layer 43 is deposited on the non-magnetic metal insertion layer 42.

Embodiment approach 2

[0060] The second embodiment: depositing a first ferromagnetic free layer 41; depositing a non-magnetic metal insertion layer 42 on the first ferromagnetic free layer 41; performing a first plasma treatment on the non-magnetic metal insertion layer 42 to treat the first plasma The non-magnetic metal insertion layer 42 after the bulk treatment is subjected to a first annealing treatment; a second ferromagnetic free layer 43 is deposited on the non-magnetic metal insertion layer 42 after the first annealing treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com