Method for preparing reference layer of magnetic tunnel junction and method for preparing magnetic tunnel junction

A technology of magnetic tunnel junction and reference layer, which is used in the manufacture/processing of electromagnetic devices, magnetic field-controlled resistors, etc., can solve problems such as surface damage of reference layer, eliminate damage or defects, improve TMR value, and improve overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

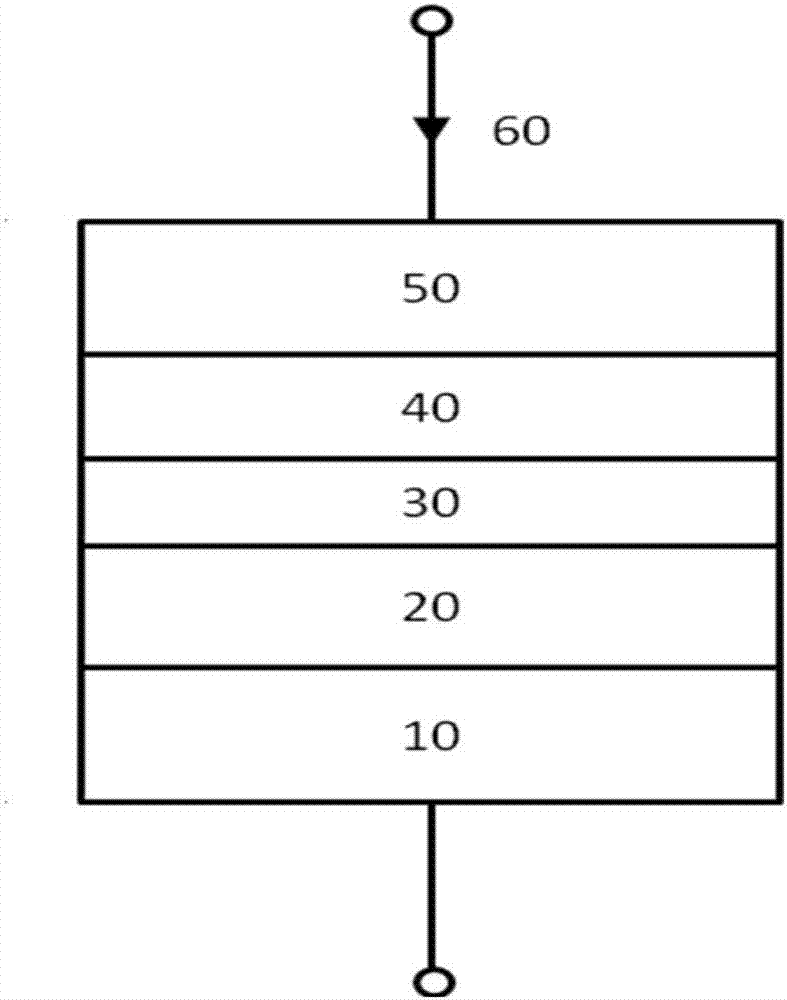

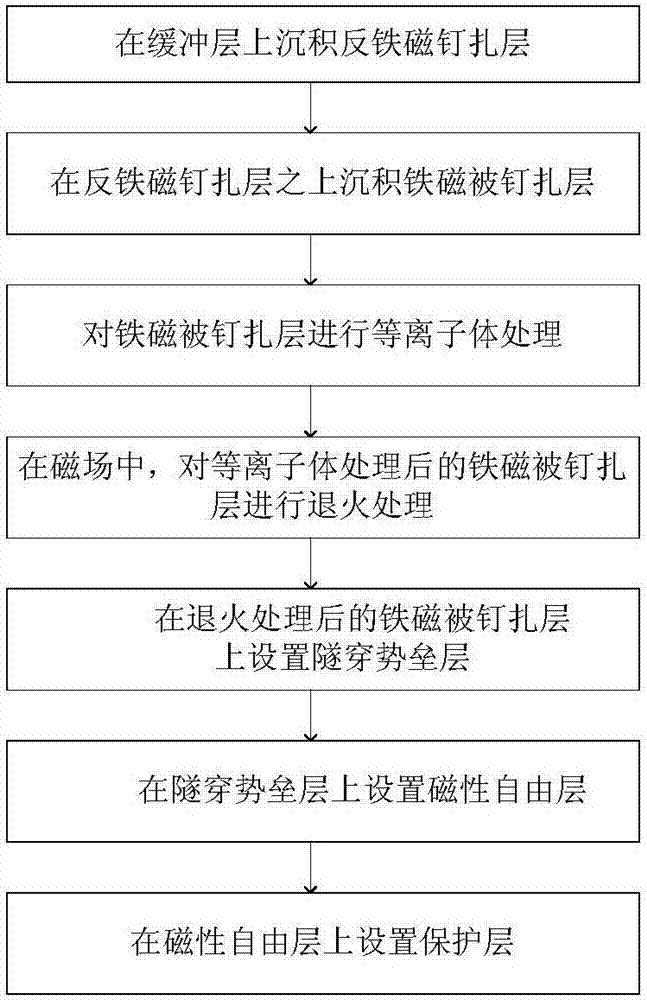

[0044] Preferably, the preparation method of the above-mentioned magnetic tunnel junction includes: setting a reference layer 20 on the buffer layer 10 using any of the above-mentioned preparation methods; setting a tunneling barrier layer 30 on the reference layer 20; setting a tunneling barrier layer 30 on the a free layer 40 ; and a protective layer is provided on the free layer 40 . The set buffer layer 10 can promote the formation of a relatively good crystal texture of the reference layer 20 grown thereon, and the protective layer 50 can protect the functional structure of the entire magnetic tunnel junction from water vapor pollution and oxidation.

[0045] The above-mentioned buffer layer 10 and protective layer 50 can be set by deposition methods, such as magnetron sputtering method, the specific setting conditions can refer to the prior art, and will not be repeated here. Preferably, the material for forming the buffer layer 10 includes Ta, Ti, TaN, TiN, Cu, Ag, Au, ...

Embodiment approach 1

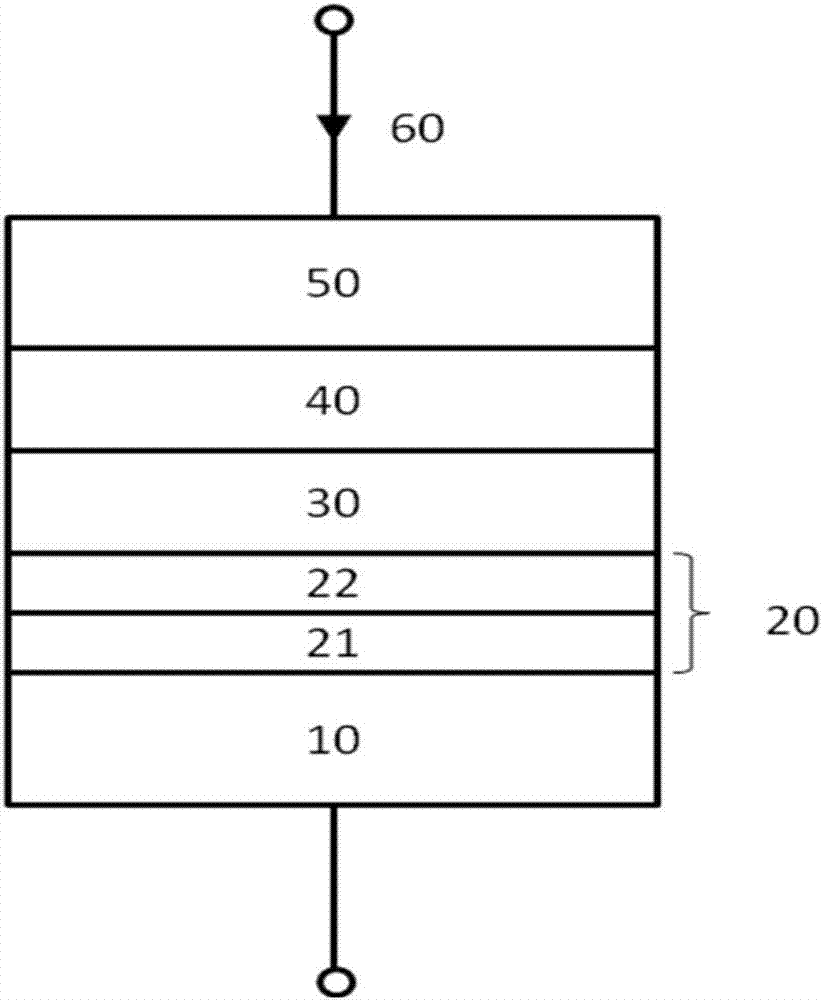

[0054] Embodiment 1: Deposit the first ferromagnetic pinned layer 221; perform plasma treatment on the first ferromagnetic pinned layer 221; perform annealing treatment on the first ferromagnetic pinned layer 221 after plasma treatment; A nonmagnetic interlayer 23 is deposited on the first ferromagnetic pinned layer 221 ; and a second ferromagnetic pinned layer 222 is deposited on the nonmagnetic interlayer 23 .

Embodiment approach 2

[0055] Embodiment 2: depositing the first ferromagnetic pinned layer 221; depositing the non-magnetic intermediate layer 23 on the first ferromagnetic pinned layer 221; depositing the second ferromagnetic pinned layer 222 on the non-magnetic intermediate layer 23 ; performing plasma treatment on the second ferromagnetic pinned layer 222 ; and performing annealing treatment on the second ferromagnetic pinned layer 222 after the plasma treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com