Semiconductor manufacturing device and method

A technology for manufacturing equipment and semiconductors, applied in semiconductor/solid-state device manufacturing, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as low-k dielectric damage, improve electrical characteristics and electromagnetic (EM) characteristics, eliminate Damage and the effect of reducing the introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described below with reference to the accompanying drawings.

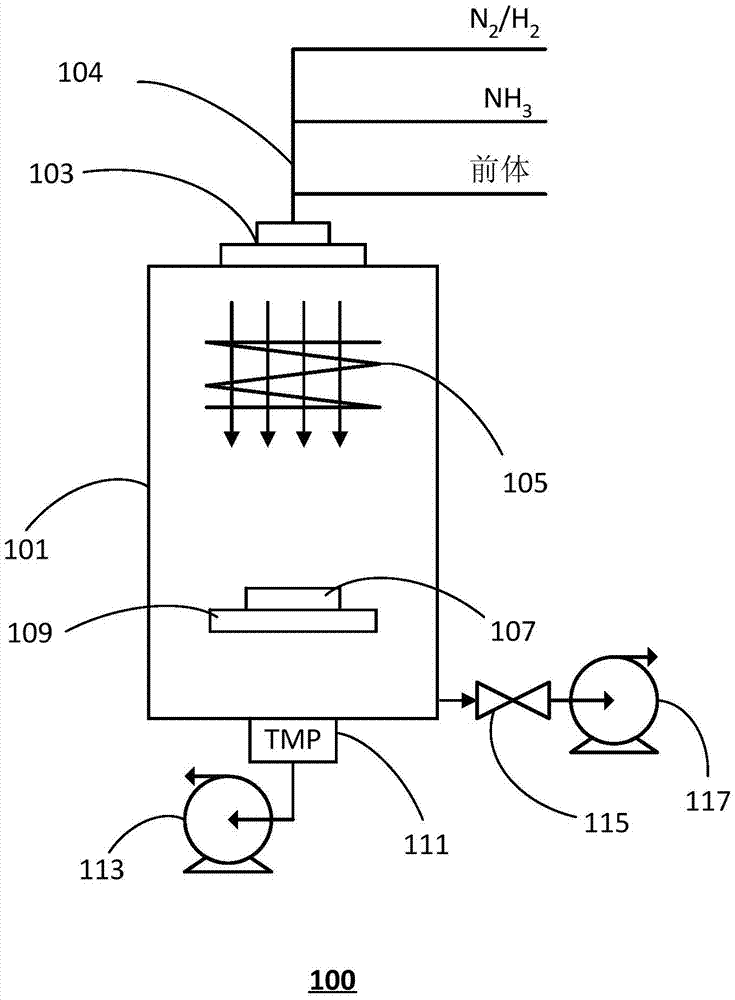

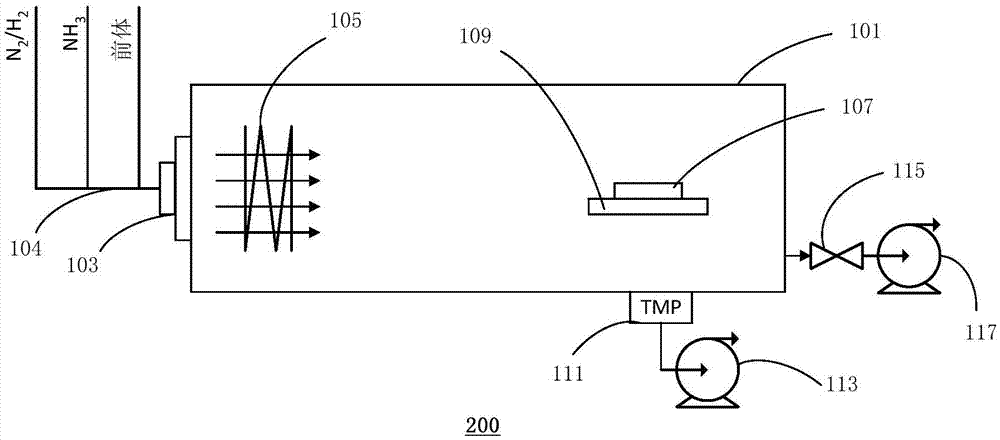

[0037] figure 1 is a schematic diagram showing a semiconductor manufacturing apparatus 100 according to an embodiment of the present invention. Such as figure 1 As shown, a semiconductor fabrication facility 100 according to one embodiment of the present invention includes a cavity housing 101 forming a closed cavity. A substrate to be processed 107 is disposed in the cavity.

[0038] The device 100 also includes a shower head 103, which is arranged on the casing 101, and is used for supplying gas from the outside of the casing to the cavity. In some implementations, the gas can include a process gas. In other implementation manners, the gas may include process gas, carrier gas, and the like. Preferably, the temperature of the gas is 80 to 110 degrees Celsius, for example 100 degrees Celsius. Depending on the application of the device, the process gas may in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com