Surface hardening process method for camshaft of diesel machine

A process method and camshaft technology, applied in cams, mechanical equipment, manufacturing tools, etc., can solve the problems of too little wear-resistant components, inability to achieve wear-resistant performance, cumbersome processes, etc., to increase service life and improve product quality. , the effect of simple operation and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

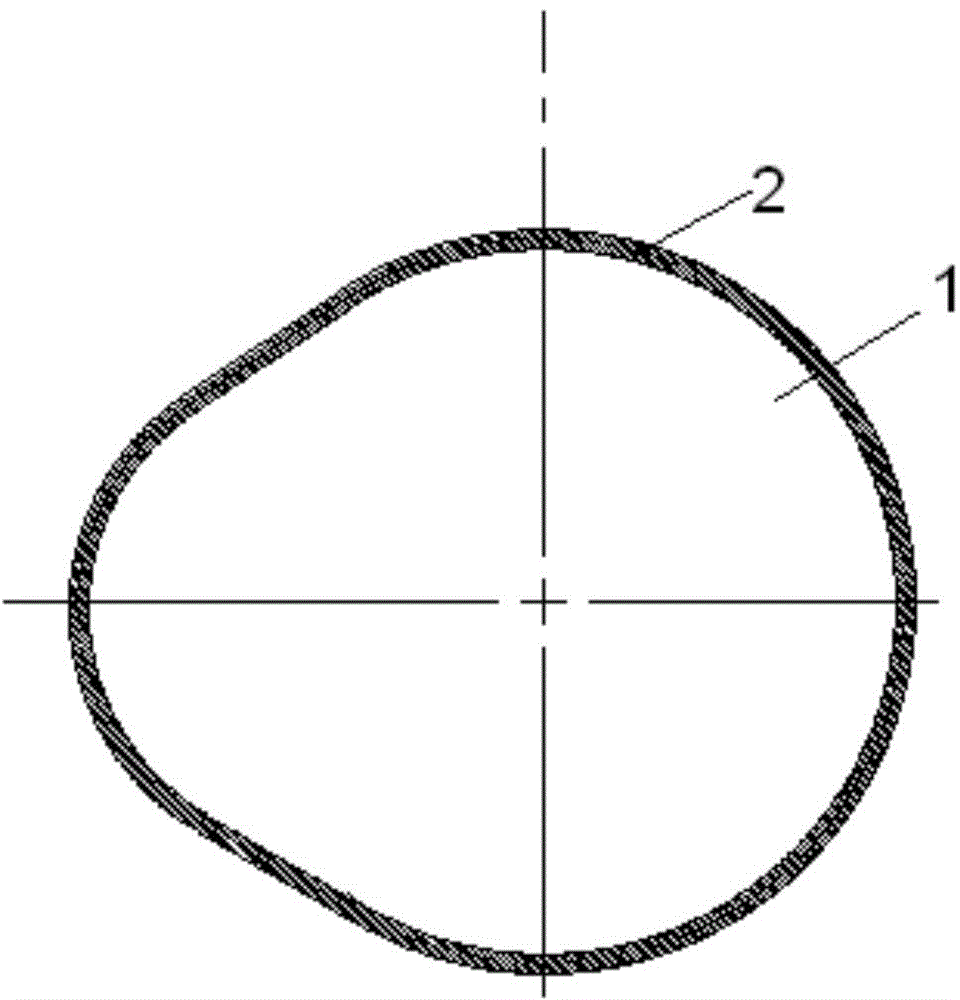

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Diesel engine camshaft surface hardening process, first rough machining the parts, and preheating the surface of the rough machined parts that are easy to wear, the preheating temperature is 150-200 ℃, and then the chemical containing high wear resistance and high hardness The component material is covered on the surface of the part by welding, and the covering thickness is 2-3mm. After the welding is completed, the whole part is quenched and tempered. Design size.

[0017] The present invention is mainly aimed at the improvement of the cam or the camshaft, so the machining process of the present invention will be described in detail by taking the camshaft as an example.

[0018] After the rough machining of the camshaft is completed, preheat the surface of the cam 1, the heating temperature is between 105-200°C, preferably to 200°C, the purpose of preheating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com