Motor assembly for vertical axis washer

A washing machine and vertical shaft technology, applied in the field of motor assembly for vertical shaft washing machines, can solve the problems of insufficient compact structure and high cost of motor occupation, and achieve the effects of low production cost, simple assembly process, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

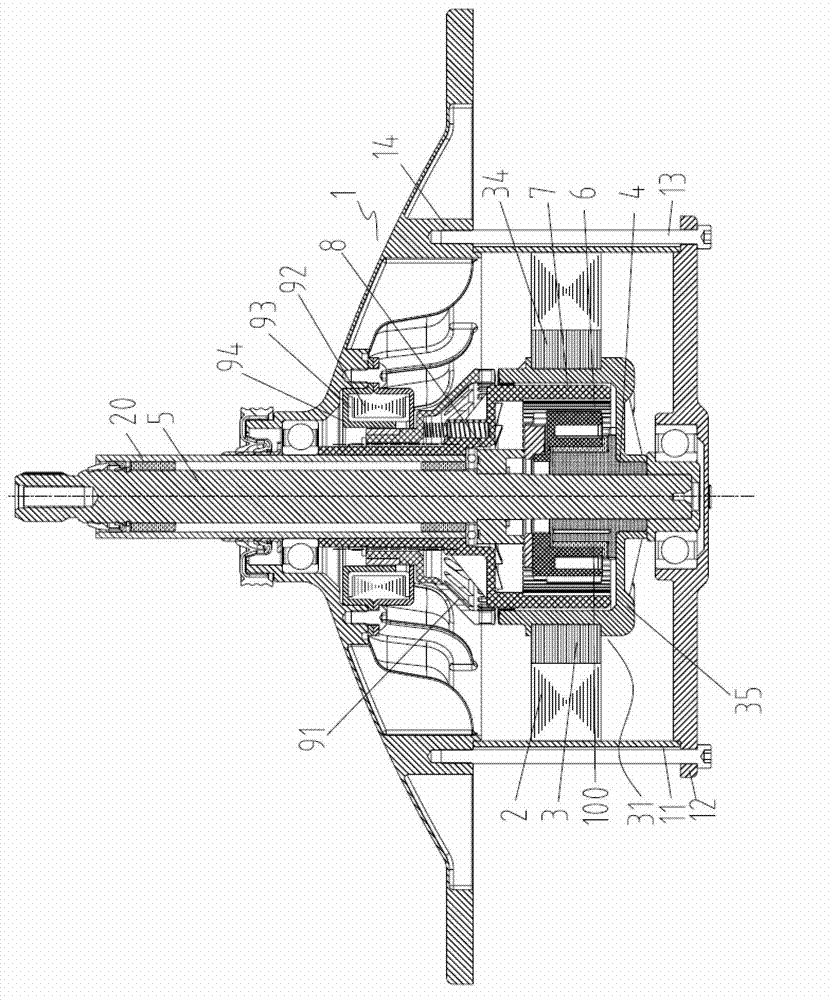

[0074] Example 1 as figure 1 , 2 As shown, it is a structural schematic diagram of the connecting device in the motor assembly for a vertical shaft washing machine of the present invention as a slider structure. Such as figure 1 As shown, the motor in this embodiment is the inner rotor motor described above. Wherein, the housing assembly 1 includes: a cylindrical housing 11 with both ends open, a motor end cover 12 connected to the bottom end of the housing 11 , a mounting plate 14 located at the top of the housing and connected to the motor end cover 12 through motor bolts 13 , and the housing 11, the motor end cover 12 and the mounting plate 14 enclose an internal space for placing other components such as the stator 2 and the inner rotor 3.

[0075] The inner rotor 3 of this embodiment includes a drive frame 31 and a cavity 32 inside the drive frame, and a locking tooth 33 is provided on the top end surface of the drive frame. Specifically, such as figure 1 , Figure ...

Embodiment 2

[0106] Example 2 as Figure 7 , 8 As shown, it is a structural schematic diagram of a motor assembly for a vertical shaft washing machine using a connecting plate structure according to the present invention.

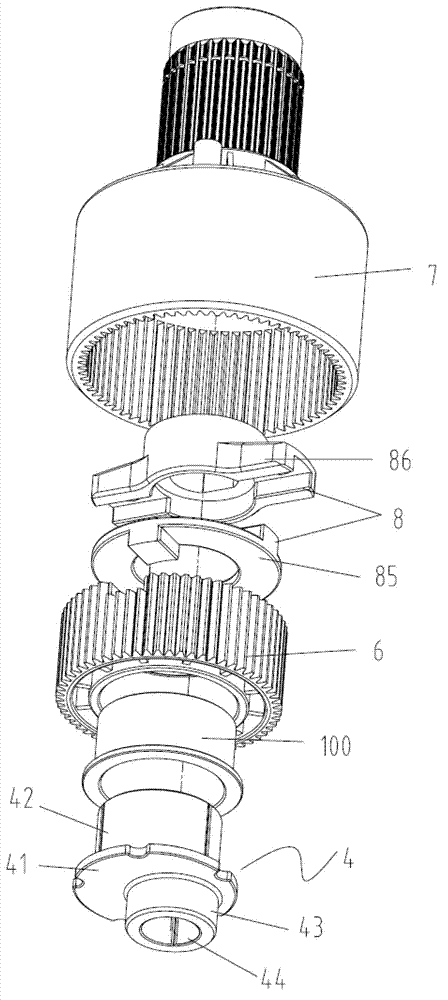

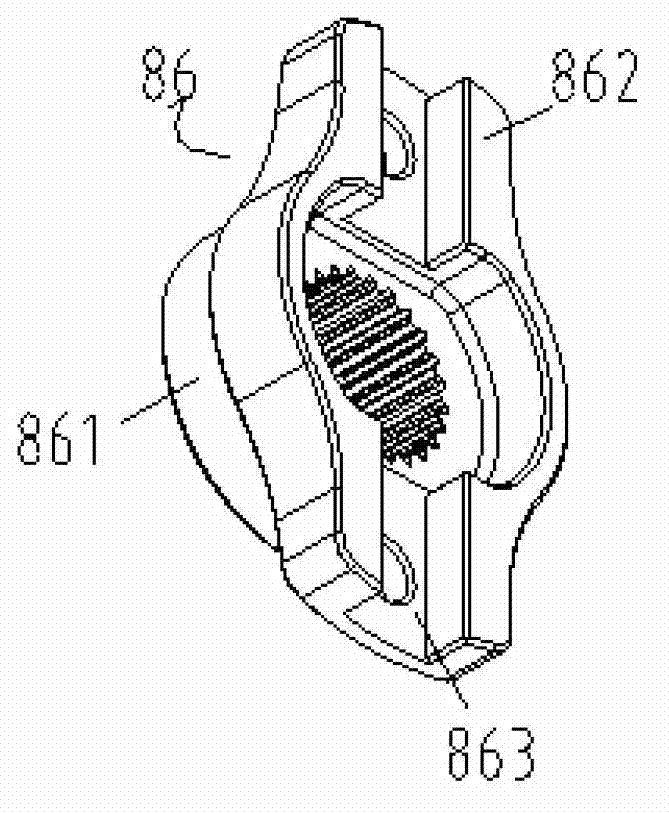

[0107] Such as Figure 7 It can be seen that the motor in this embodiment is also the inner rotor motor described above. Wherein, an inner rotor with a cavity is arranged in the housing assembly, and a reduction mechanism is arranged in the cavity of the inner rotor, and the reduction mechanism includes an eccentric sleeve 4, a spur gear 6, an inner ring gear 7 and a connecting device 8, In this embodiment, the connection device adopts a connection plate structure.

[0108] In this embodiment, the inner rotor motor, the housing assembly, the clutch device and the eccentric sleeve and the inner ring gear in the reduction mechanism are all the same as those in Embodiment 1, and will not be repeated here. Only the connection device and the connection device will be desc...

Embodiment 3

[0117] Embodiment 3 Embodiment 3 is a further preferred embodiment of Embodiment 1 and Embodiment 2. In order to improve the washing effect, this embodiment provides a washing method using a hysteresis damper and its application to a motor assembly for a vertical shaft washing machine.

[0118] The motor assembly for a vertical shaft washing machine in this embodiment, on the basis of the foregoing, further includes: a hysteresis damper is installed and connected to the outside of the dehydration shaft sleeve, and the hysteresis damper can generate a damping force on the dehydration shaft sleeve, so that the dehydration shaft sleeve The rotation speed of the dehydration sleeve is equal to or less than the rotation speed of the washing shaft,

[0119] Such as Figure 14 It can be seen that the motor in this embodiment is also the inner rotor motor described above. Wherein, an inner rotor with a cavity is arranged in the housing assembly, and a reduction mechanism is arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com