Three-branch bi-directional hydraulic squeezing and expanding machine

A two-way hydraulic and extrusion machine technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems that affect the stability of buildings, the bearing plate space is easy to collapse, and the bearing capacity cannot be obtained, so as to improve the application Effect and efficiency, achieve consistency and stability, and improve the effect of axial running ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

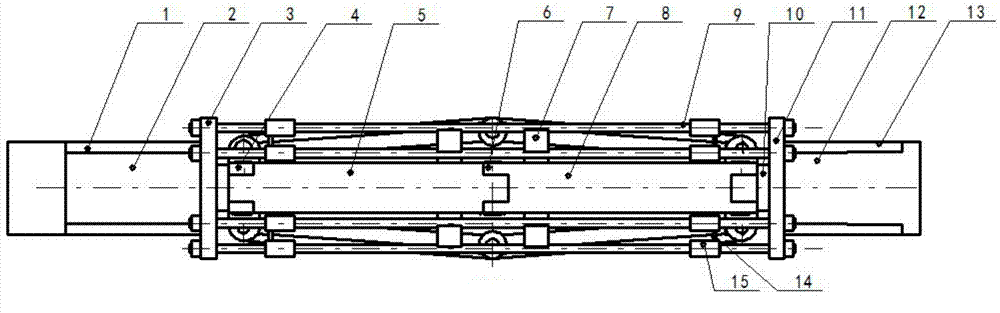

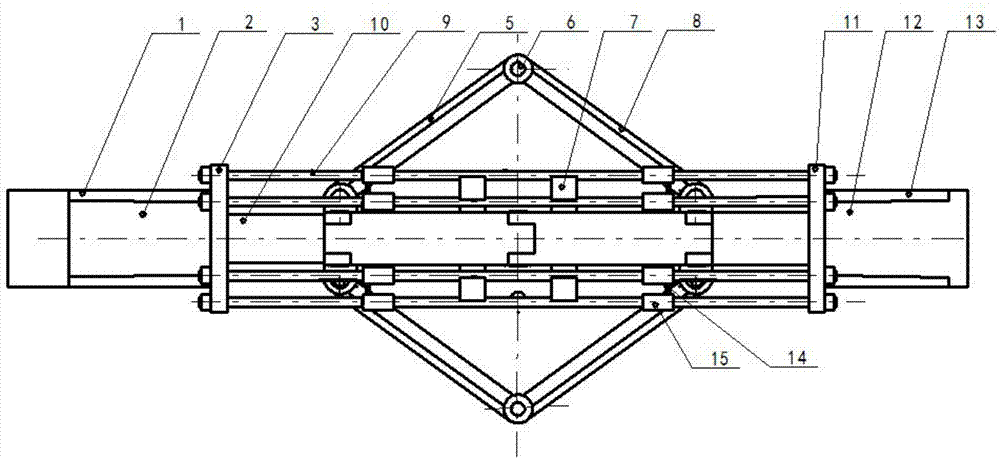

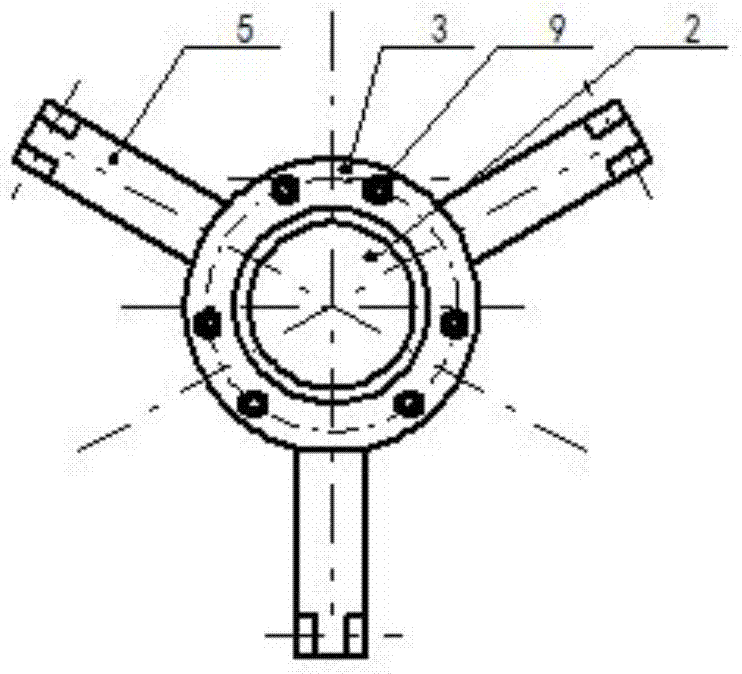

[0026] A three-fork two-way hydraulic extrusion machine, comprising an upper head 1, a lower head 13, an upper bow pressing arm 5, a lower bow pressing arm 8, an upper oil cylinder 2 and a lower Oil cylinder 12, the piston rod 10 ends of the upper and lower oil cylinders are all hinged through the hinge seat 4 and one end of the upper bow pressing arm and the lower bow pressing arm are hinged, and the other ends of the upper bow pressing arm and the lower bow pressing arm are hinged through the middle hinge seat 6. The upper bow pressing arm and the lower bow pressing arm are coaxially and evenly spaced and hinged on the ends of the respective piston rods. The upper bow pressing arm and the lower bow pressing arm shown in the drawings of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com