(TiB2 plus TiC)/Ti3SiC2 multi-phase ceramic material and prepration method thereof

A technology of composite ceramics and raw materials, which is applied in the field of ceramic matrix composite materials and its preparation, can solve problems such as complex preparation process, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

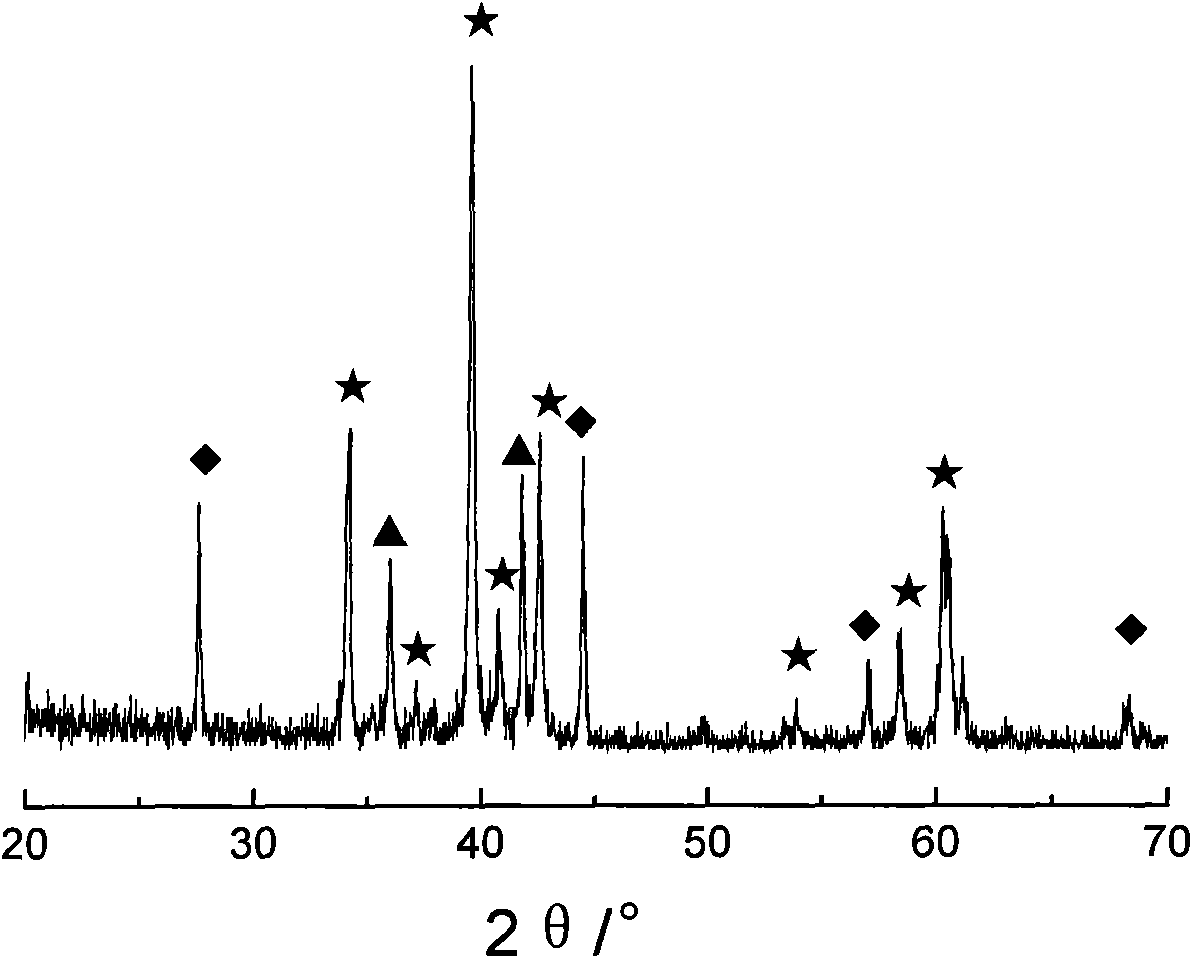

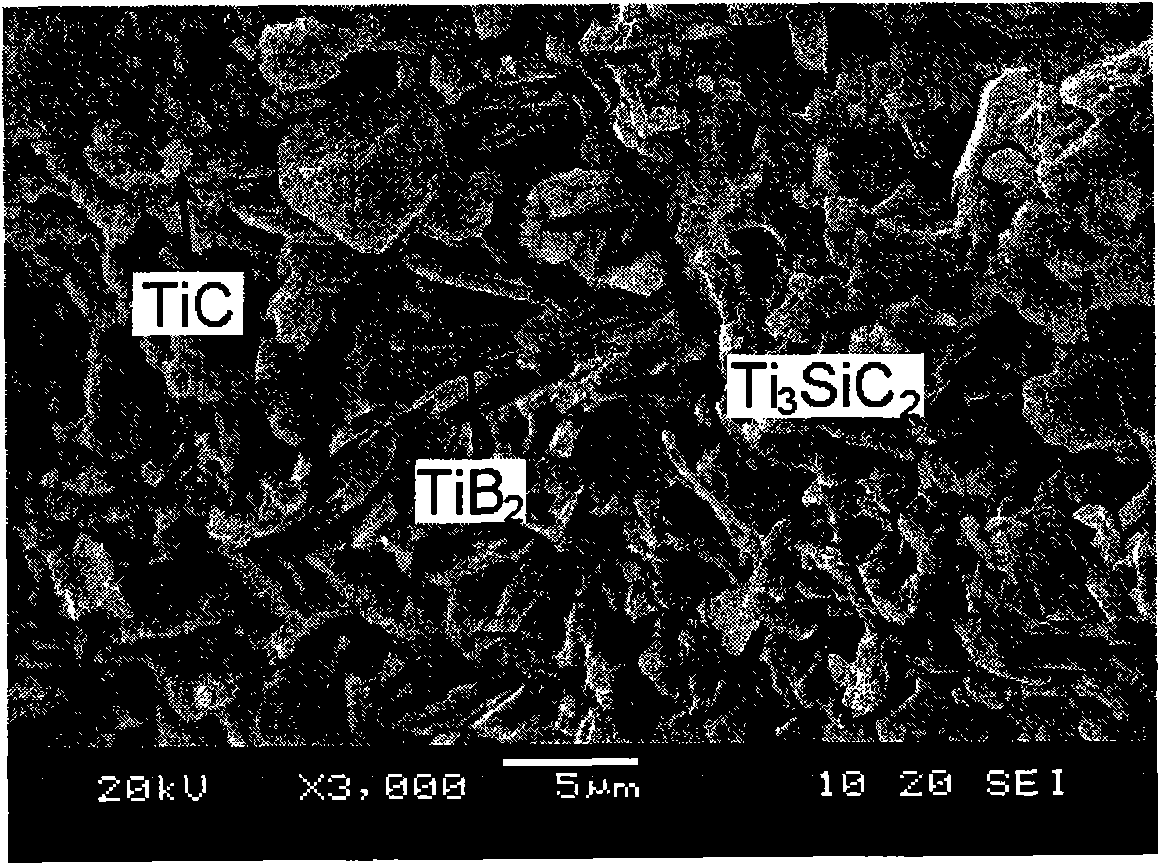

[0022] molar ratio n(TiH 2 ):n(Si):n(C):n(B 4 C)=3.98:1.14:2:0.28 Weigh the raw material TiH 2 Powder (-300 mesh powder), Si powder (-300 mesh powder), graphite powder (10 micron powder) and B 4 After C powder (5 micron powder), dry mix it in a polyethylene tank for 24 hours, place it in a graphite mold coated with BN for cold pressing, and hot press and sinter it in an argon atmosphere. Pre-incubation at ℃ for 1 hour without pressure, and then increase the temperature to 1500°C at a rate of 20°C / min, and increase the pressure to 25MPa at a rate of 2MPa per 50°C increase, and then hold for 2h. The density of the obtained block material reaches 99.8%, the three-point bending strength of the material tested on the universal testing machine is greater than 680MPa, and the fracture toughness of the material measured by the unilateral notched beam method is greater than 8.5MPa m 1 / 2 . Carry out XRD analysis to the obtained product, such as figure 1 Products shown are manufactu...

Embodiment 2

[0024] molar ratio n(TiH 2 ):n(Si):n(C):n(B 4 C)=3.59:1.09:2:0.1 7 Weigh the raw material TiH 2 Powder (-300 mesh powder), Si powder (-300 mesh powder), graphite powder (15 micron powder) and B 4 C powder (10 micron powder) is dry mixed in a polyethylene tank for 24 hours, then placed in a BN-coated graphite mold for cold pressing, then hot-pressed and sintered in an argon atmosphere, and raised to 900 °C at a rate of 50 °C / min Pre-insulate without pressure for 1 hour, then raise the temperature to 1500°C at a rate of 20°C / min, and increase the pressure to 25MPa at a rate of 2MPa per 50°C increase, and then hold for 2h. The density of the obtained block material reaches 99.8%, the three-point bending strength of the material tested on the universal testing machine is greater than 680MPa, and the fracture toughness of the material measured by the unilateral notched beam method is greater than 8.5MPa m 1 / 2 .

Embodiment 3

[0026] molar ratio n(TiH 2 ):n(Si):n(C):n(B 4 C) = 3.59: 1.09: 2: 0.1 7 Weigh and weigh the raw material TiH 2 Powder (-300 mesh powder), Si powder (-300 mesh powder), graphite powder (15 micron powder) and B 4 C powder (3 micron powder) is dry mixed in a polyethylene tank for 20 hours, then placed in a BN-coated graphite mold for cold pressing, then hot-pressed and sintered in an argon atmosphere, and raised to 800 °C at a rate of 30 °C / min Pre-insulate without pressure for 50 minutes, then raise the temperature to 1600°C at a rate of 20°C / min, and increase the pressure to 22MPa at a rate of 1.5MPa per 50°C increase, and then hold for 2 hours. The density of the obtained block material reaches 99.9%, the three-point bending strength of the material tested on the universal testing machine is greater than 680MPa, and the fracture toughness of the material measured by the unilateral notched beam method is greater than 9MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com