Method for preparing foamed ceramic through hydrophobic flocculation

A technology of foam ceramics and water flocculation, which is applied to ceramic products, other household utensils, household utensils, etc. It can solve the problems of complicated process operation and many types of organic matter addition, and achieve the effect of simple process, good fluidity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

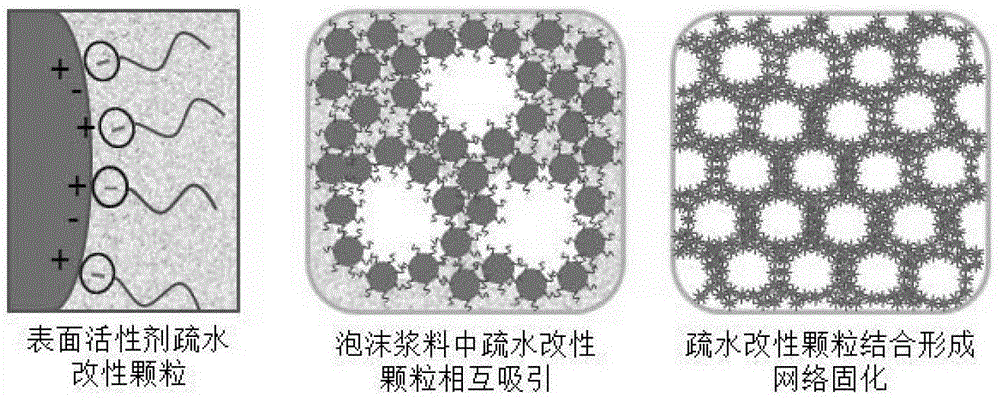

[0041] Preparation of foam slurry. Specifically, the water-based ceramic slurry uniformly dispersed with the surfactant is mechanically stirred and foamed to obtain a foamed slurry. Wherein, the mechanical foaming is stirring for 1 to 5 minutes at a rotation speed of 600 to 2000 revolutions / minute. In the present invention, the hydrophobically modified particles can act as a particle stabilizer to stabilize foam.

[0042] Preparation of foam body. Specifically, the above-mentioned foam slurry is injected into a mold for forming, and cured (in-situ curing at room temperature), demolded, and dried to obtain a foam body. In the present invention, the foam slurry after mechanical stirring and foaming is injected into a porous vented mold and placed at room temperature. Under the mutual hydrophobic interaction between the hydrophobic particles, flocculation and coagulation are generated, and the mold can be demolded after 24 hours, thereby obtaining a certain strength Ceramic foam ...

Embodiment 1

[0047] (1) Preparation of slurry: use alumina powder with median particle size D50=450nm as raw material, use ultrapure water as solvent, and use 1mol / L HCl to adjust the pH value of the slurry (pH=5); prepare dispersion by ball milling Uniform ceramic slurry with a solid content of 30vol.%;

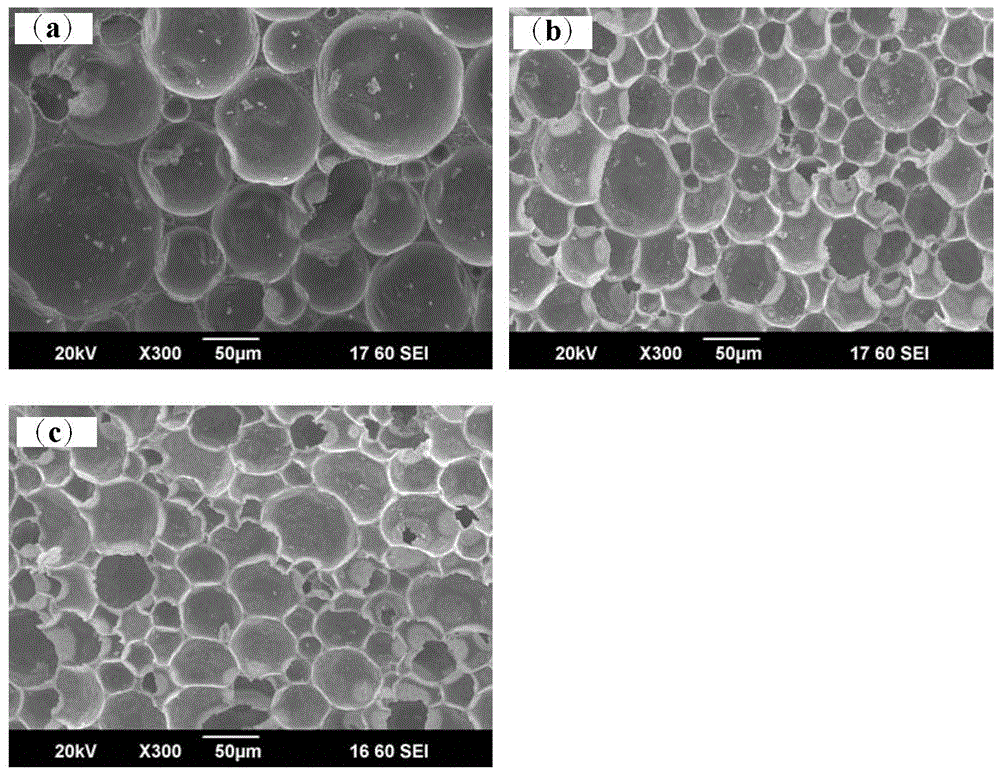

[0048] (2) Hydrophobic modification: add 0.1 wt.% (relative to the mass of the powder) dodecyl sulfate triethanolamine to the slurry, and continue ball milling for 10 minutes;

[0049] (3) Stirring and foaming: transfer the above hydrophobically modified ceramic powder slurry to a measuring cup, adjust the speed of the stirrer to 1000 rpm, and mechanically stir and foam for 2 minutes;

[0050] (4) Injection molding and curing: Inject the foam slurry into a porous metal mold lined with paper, leave it for 24 hours, demold, and dry at room temperature for 48 hours;

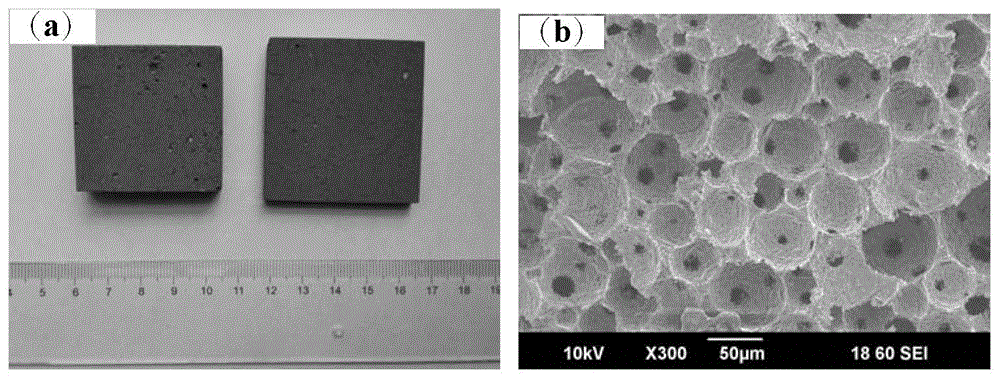

[0051] (5) Sintering: the foam ceramic green body is kept at 1550°C for 2 hours, and then cooled with the furnace to obtain alumina ...

Embodiment 2

[0053] The preparation process is similar to that of Example 1, except that 0.17 wt.% (relative to the mass of the powder) dodecyl sulfate triethanolamine is added to the slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com