Method for preparing tantalum disilicide coating

A tantalum disilicide coating technology, which is applied in the field of plasma spraying technology to prepare tantalum disilicide coatings, can solve the problems of small film thickness and many impurities, and achieve uniform microstructure, good chemical stability and low temperature resistance. The effect of oxidation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

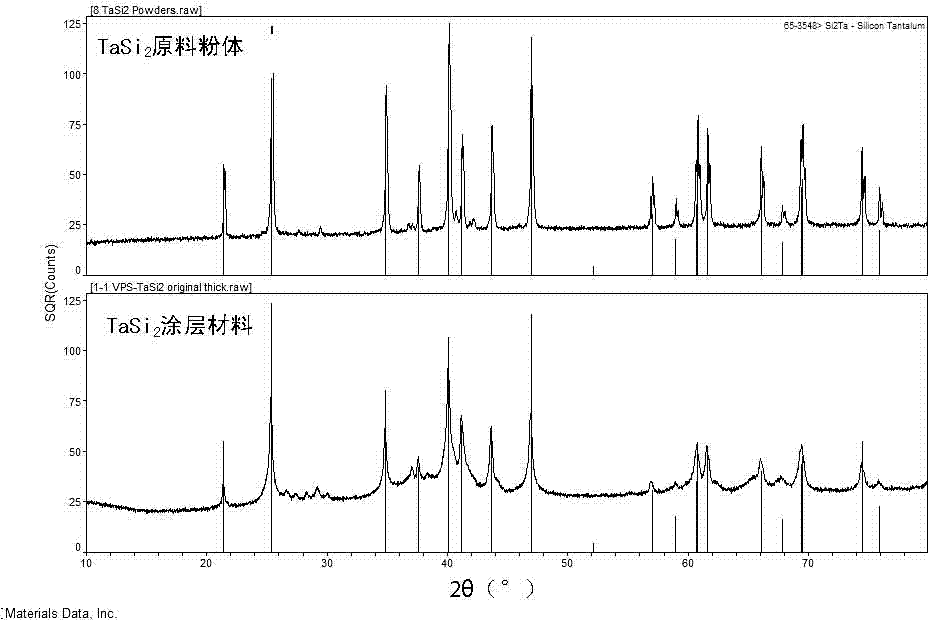

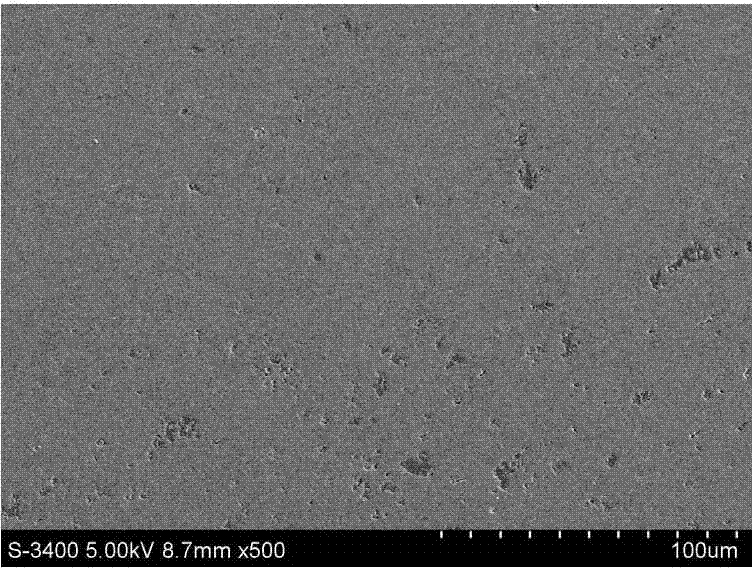

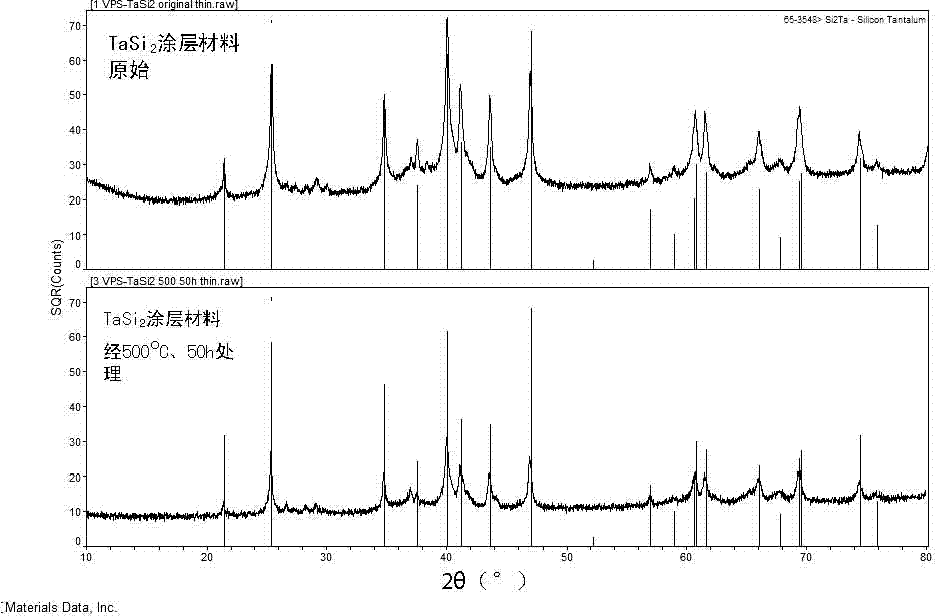

[0036] Embodiment 1: select the TaSi whose particle size distribution is 15~50 microns and purity is 98wt% 2 Powder, using vacuum plasma spraying technology, select the process parameters listed in Table 3, prepare TaSi with graphite as the matrix 2 coating. XRD results ( figure 1 ) indicates that the coating consists of a single TaSi 2 Phase composition (PDF65-3548), free of impurity phases. cross-sectional morphology ( figure 2 ) shows that TaSi 2 The coating has a dense microstructure, and the coating thickness is 350-380 μm. The coating is peeled off from the graphite substrate, and after heat treatment at 500°C for 50 hours, the XRD pattern of the coating after heat treatment is the same as that of the original TaSi 2 The XRD patterns of the coating are basically the same ( image 3 ). It shows that the tantalum disilicide coating prepared by this method has good chemical stability and low temperature oxidation resistance.

[0037] Table 3 Vacuum plasma spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com