Method for promoting sintering of titanium boride ceramic by using reaction aids

A reaction aid, titanium boride technology, applied in the field of structural ceramics, can solve the problems of unfavorable and impacted ceramic high-temperature mechanical properties and corrosion resistance, and achieve small particle size, adjustable material components, and uniform microstructure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

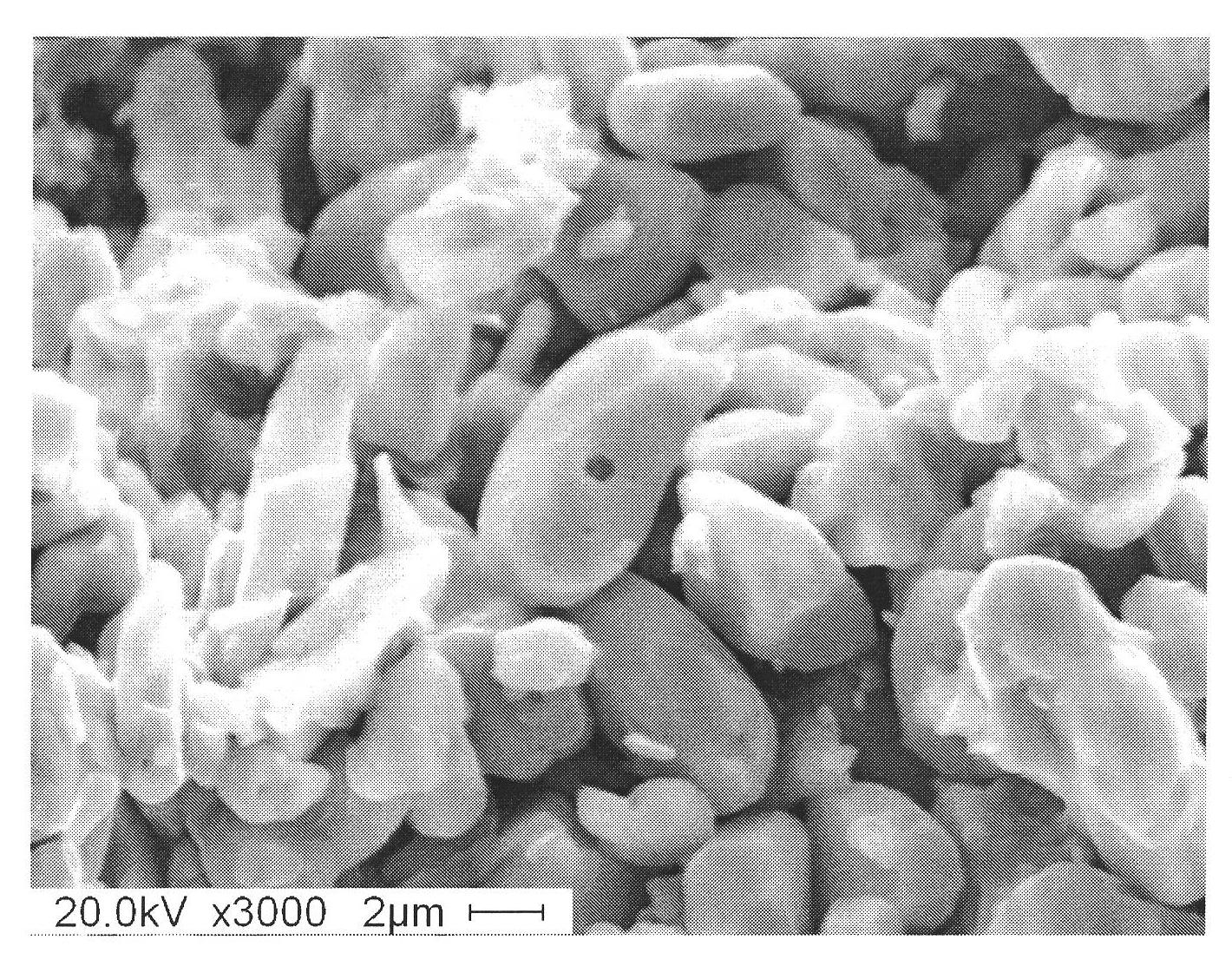

Examples

Embodiment 2

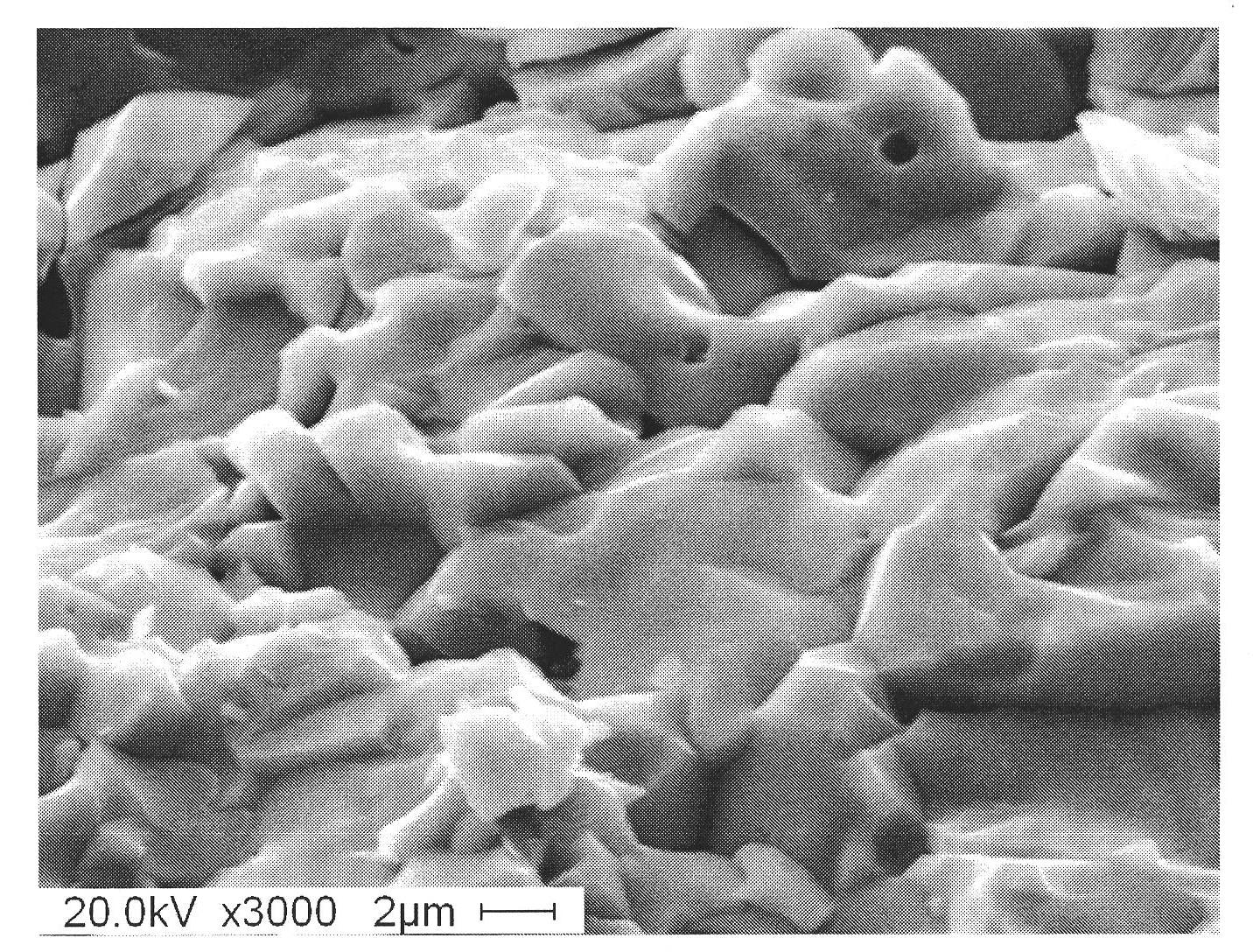

[0032] According to the method in Example 1, titanium boride powder containing reactive sintering aids was obtained. Put the uniformly mixed powder in a graphite mold coated with BN on the inner wall surface, and carry out reaction sintering in vacuum. The heating rate during sintering is 10°C / min. Pressure, under an argon atmosphere, the temperature was raised to 2000°C at a rate of 10°C / min, and the pressure was maintained for 1h. The material density reaches 98%. Microstructure such as figure 2 shown.

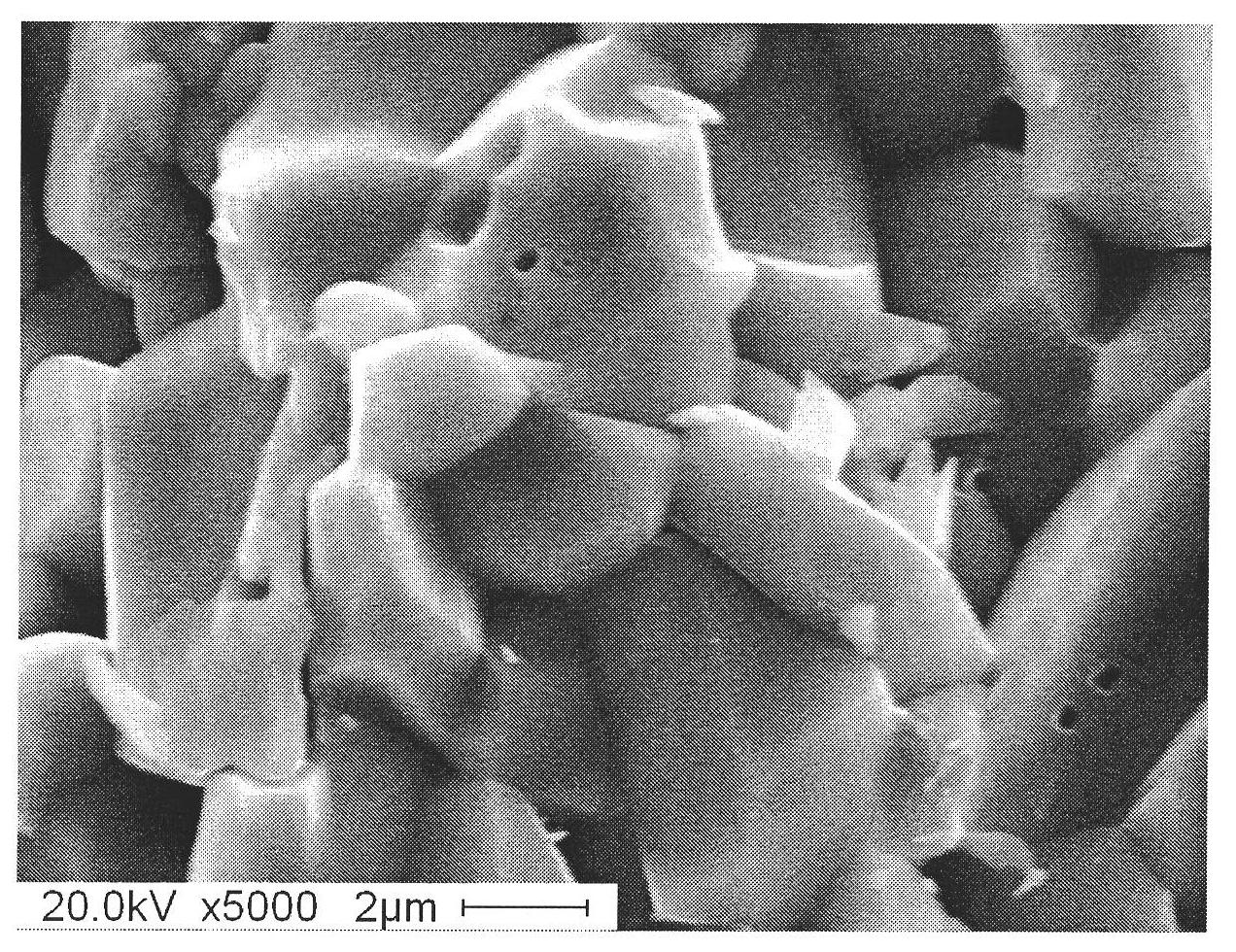

Embodiment 3

[0034] Using titanium boride (4 The amount of C added was 10 wt%. Add 2.17g of titanium powder and 0.83g of boron carbide powder into a plastic tank, add ethanol and ultrasonically disperse for 15 minutes, mix with silicon nitride balls on a roller mixer for 12 hours, add 27g of titanium boride, and mix for 12 hours , and then dried with a rotary evaporator and passed through a 200-mesh sieve to obtain titanium boride powder containing reactive sintering aids. Ceramics were prepared according to the method of Example 1, the sintering temperature was 1800° C., and the heat preservation and pressure holding were carried out for 1 hour. The material density reaches 74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com