Sintering aid for yttrium aluminum garnet-based fluorescent transparent ceramic and using method thereof

A technology of transparent ceramics and sintering aids, which is applied in the field of sintering aids for the preparation of garnet-based transparent ceramic fluorescent materials, which can solve the problem of difficult to obtain high-quality garnet-based transparent ceramic fluorescent materials with microstructure and difficulty in suppressing abnormally long crystal grains Large, difficult to uniformly control the uniform distribution of grain size, etc., to achieve high optical quality and compact microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

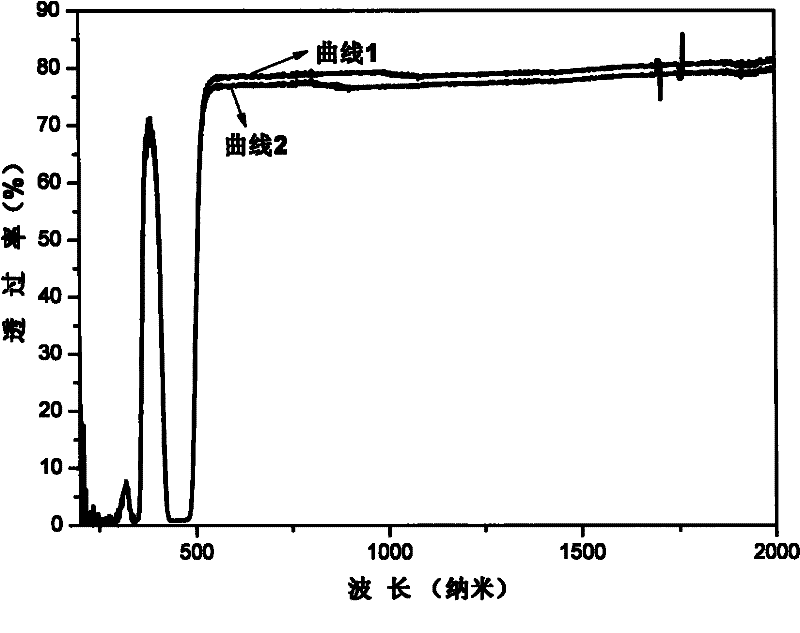

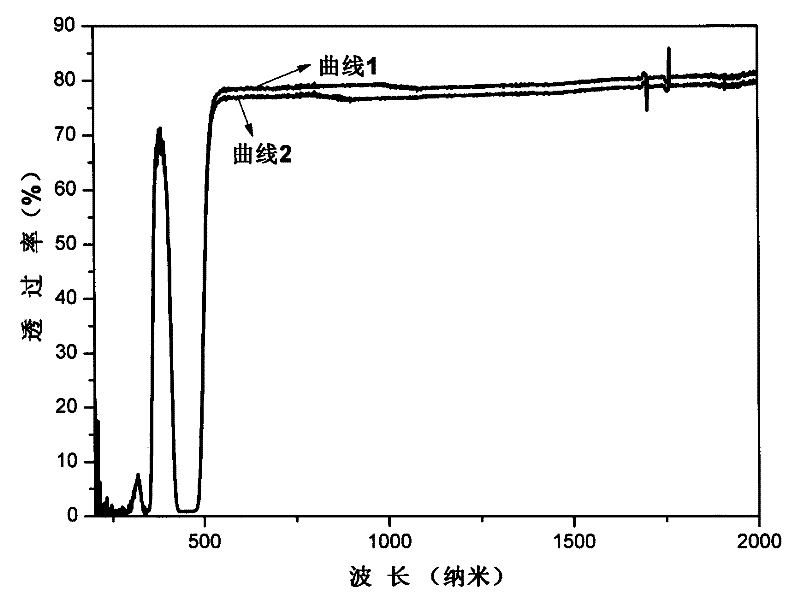

[0013] Example 1 is used to prepare cerium-doped yttrium aluminum garnet transparent ceramic fluorescent material

[0014] Using commercial cerium oxide (CeO) with a purity of 99.9% 2 ), yttrium oxide (Y 2 o 3 ) and alumina (Al 2 o 3 ) powder, press Ce 0.001 Y 2.999 al 5 o 12 The composition and configuration of the powder raw materials are 30g in total, add 0.3wt% tetraethyl orthosilicate (TEOS) with a silicon oxide content ≥ 28.4%, 0.01wt% MgO with a purity of 99.9% as additives, and grind the powder by ball milling and other means Mixing, refinement, granulation and tableting after drying the powder; then apply a cold isostatic pressure above 200MPa to press it into a green body, then pre-fire to remove organic components; finally put it into a vacuum sintering furnace at 1700°C After sintering for 5 hours, the vacuum degree in the sintering and heat preservation stage is better than 1.0×10 -3 Pa, get Ce 0.001 Y 2.999 al 5 o 12 Transparent ceramic fluorescent m...

Embodiment 2

[0015] Example 2 is used to prepare cerium and chromium co-doped yttrium aluminum garnet transparent ceramic fluorescent material

[0016] Using commercial cerium oxide (CeO) with a purity of 99.999% 2 ), yttrium oxide (Y 2 o 3 ), chromium oxide (Cr 2 o 3 ) and alumina (Al 2 o 3 ) powder, press Ce 0.001 Cr 0.001 Y 2.998 al 5 o 12 The composition and configuration of the powder raw materials are 30g in total, add 0.7wt% tetraethyl orthosilicate (TEOS) with a silicon oxide content ≥ 28.4%, 0.8wt% MgO with a purity of 99.99% as additives, and grind the powder by ball milling and other means Mixing and refinement, the powder is dried and then granulated and tableted; then it is pressed into a green body with a cold isostatic pressure above 200MPa, and then pre-fired to remove organic components; finally put into a hot-pressed sintering furnace Sintering at 1400℃ for 2 hours under 30MPa, the vacuum degree in the sintering and holding stage is better than 2.5×10 -3 Pa, t...

Embodiment 3

[0017] Example 3 is used to prepare cerium and gadolinium co-doped yttrium aluminum garnet transparent ceramic fluorescent material

[0018] Using commercial cerium oxide (CeO) with a purity of 99.9% 2 ), yttrium oxide (Y 2 o 3 ), gadolinium oxide (Gd 2 o 3 ) and alumina (Al 2 o 3 ) powder, press Ce 0.001 Y 2.899 Gd 0.01 al 5 o 12 The composition and configuration of the powder raw materials are 30g in total, add 0.5wt% tetraethyl orthosilicate (TEOS) with a silicon oxide content ≥ 28.4%, 0.1wt% MgO with a purity of 99.999% as additives, and grind the powder by means of ball milling Mixing, refinement, granulation and tableting after drying the powder; then apply a cold isostatic pressure above 200MPa to press it into a green body, then pre-fire to remove organic components; finally put it into a vacuum sintering furnace at 1650°C After sintering for 10 hours, the vacuum degree in the sintering and heat preservation stage is better than 1.0×10 -3 Pa, Ce with dense ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com