Ceramics of containing powder body of cubic silicon nitride, and preparation method

The technology of cubic silicon nitride powder and cubic silicon nitride is applied in the field of ceramics containing cubic silicon nitride powder and its preparation, which can solve the problems of inapplicability and achieve high density, uniform microstructure and mechanical properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

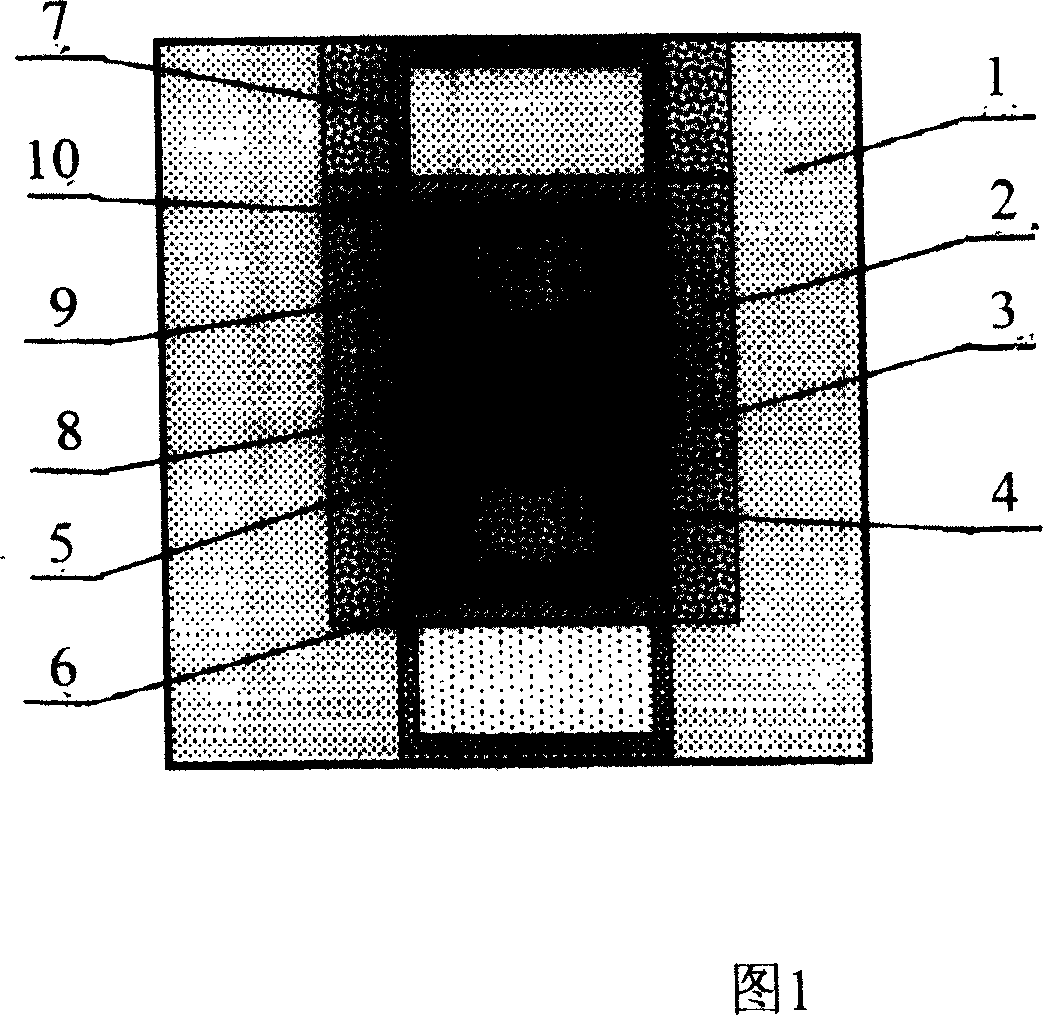

[0033] Embodiment 1: see accompanying drawing 1-4.

[0034] A preparation method of ceramics containing cubic silicon nitride powder, comprising the following steps:

[0035] a. Grinding of ingredients: according to γ-Si 3 N 4 25% (average particle size 30nm), α-Si 3 N 4 70% (200 mesh), sintering aid (both 200 mesh) Y 2 o 3 1%, Al 2 o 3 2%, La 2 After the weight percent example of 0.2% is measured and compounded respectively, the grinding medium is mixed and ground with absolute ethanol for 4 hours to obtain a uniformly dispersed composite powder;

[0036] b. Drying: Dry the ground composite powder in an infrared drying oven (power 500W) for 10 minutes;

[0037] c. Cold isostatic pressing granulation: Press the dried composite powder under the pressure of 250MPa by cold isostatic pressing, take it out and crush it, and pass it through a 1-3mm square hole sieve to obtain uniform granules;

[0038] d, dry pressing molding: pass the granulated particles through a steel ...

Embodiment 2

[0050] Embodiment 2: see accompanying drawing 1,5~7.

[0051] A preparation method of ceramics containing cubic silicon nitride powder, comprising the following steps:

[0052] a. Grinding of ingredients: according to γ-Si 3 N 4 95% (average particle size 30nm), sintering aid (both 200 mesh) Y 2 o 3 1%, Al 2 o 3 2%, La 2 After the weight percent example of 0.2% is measured and compounded respectively, the grinding medium is mixed and ground with absolute ethanol for 4 hours to obtain a uniformly dispersed composite powder;

[0053] b. Drying: Dry the ground composite powder in an infrared drying oven (power 500W) for 10 minutes; control the temperature within 120°C;

[0054] c. Cold isostatic pressing granulation: Press the dried composite powder under the pressure of 250MPa by cold isostatic pressing, take it out and crush it, and pass it through a 1-3mm square hole sieve to obtain uniform granules;

[0055] d, dry pressing molding: pass the granulated particles throu...

Embodiment 3-9

[0063] A kind of pottery containing cubic silicon nitride powder body, the weight percent example composition of this pottery is shown in the following table respectively:

[0064]

[0065] γ-Si mentioned in the table 3 N 4 The particle size is submicron to nanometer; the Al 2 o 3 , ZrO 2 , α or β phase Si 3 N 4 , SiC, BN or AlN have a particle size of tens of microns to submicrons; the sintering aid Y 2 o 3 、Al 2 o 3 , La 2 The particle size of O is tens of micrometers to submicrometers.

[0066] The preparation method of the ceramics containing cubic silicon nitride powder in each embodiment in the table is the same as that of Example 1 or 2, or the steps, conditions and parameters of the process described in the content of the present invention, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| bulk modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com