Method for preparing SiC/TiC composite ceramic by precursor method

A technology of composite ceramics and composite powders, which is applied in the field of preparation of SiC/TiC composite ceramics, can solve the problems of uneven microstructure, high sintering temperature, coarse grains, etc., and achieve excellent oxidation resistance and chemical corrosion resistance. The effect of low temperature and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 3.69 grams of PCS to 50 ml of cyclohexane, fully dissolve it, and prepare a PCS transparent solution, and then add 1 gram of Ti powder into it. Heating while stirring, the temperature was gradually raised to 60°C, and kept stirring for 60 minutes. Then put it into a drying oven to continue evaporating the solvent for 60 minutes, and dry to obtain a mixture of PCS and Ti powder.

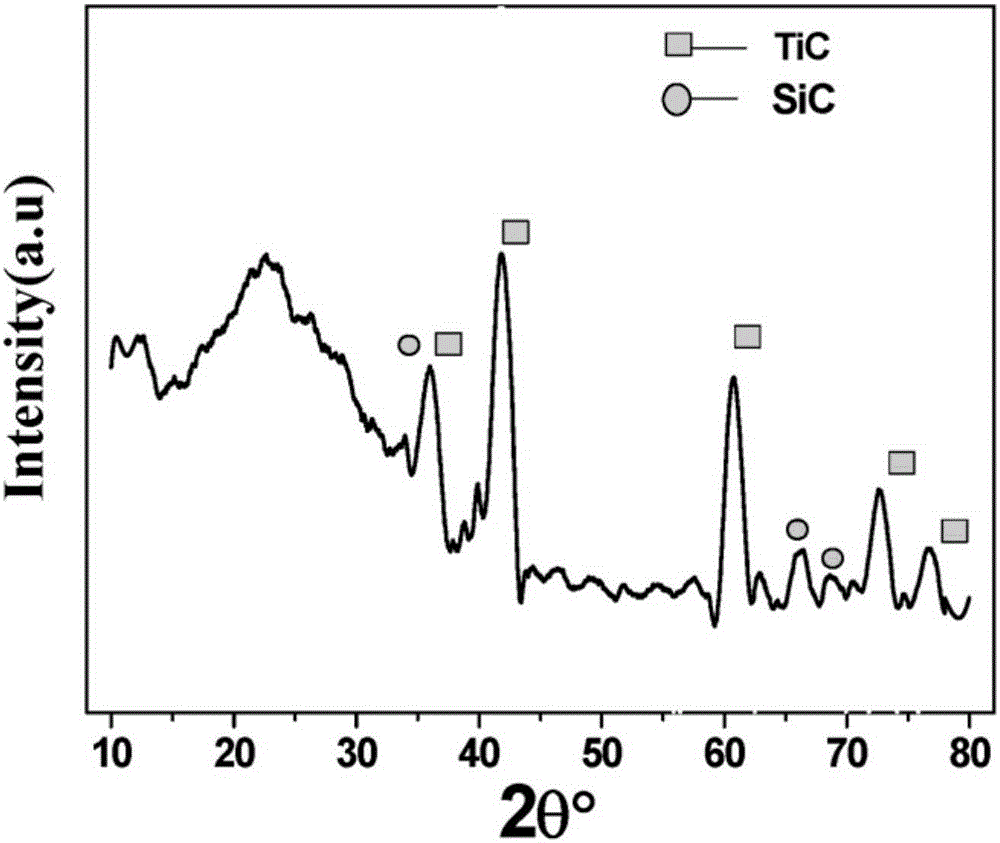

[0023] (2) Pyrolyze the mixture of the obtained PCS and Ti powder in a high-temperature furnace, the pyrolysis atmosphere is argon, the heating rate is 5°C / min, from room temperature to 1050°C, and the temperature is kept for 60 minutes to obtain a SiC / TiC composite powder.

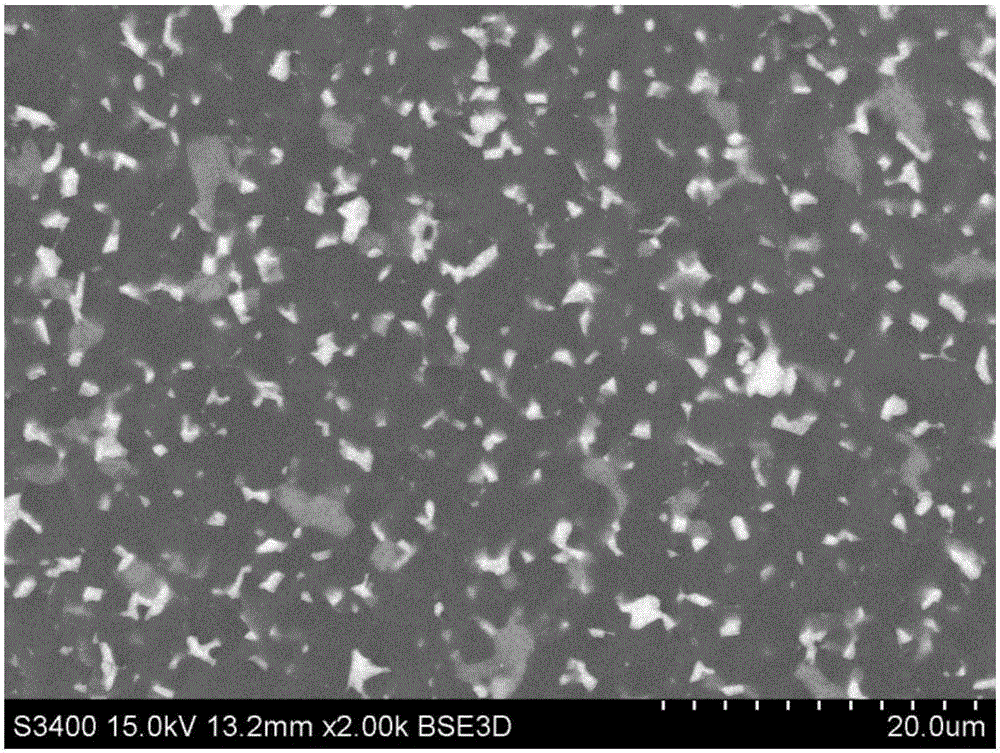

[0024] (3) Put the obtained SiC / TiC composite powder into a graphite mold, put it into a hot-press sintering furnace, raise the temperature to 1500°C at a rate of 15°C / min under vacuum, fill it with argon, and sinter with a sintering pressure of 25MPa, and hold for 30 Minutes to obtain SiC / TiC composite ceramics....

Embodiment 2

[0026] (1) Add 3.69 grams of PCS to 50 ml of cyclohexane, fully dissolve, and prepare a PCS transparent solution, and then add 1.5 grams of Ti powder to it. Heating while stirring, the temperature was gradually raised to 63°C, and kept stirring for 60 minutes. Then put it into a drying oven to continue evaporating the solvent for 60 minutes, and dry to obtain a mixture of PCS and Ti powder.

[0027] (2) Pyrolyze the mixture of the obtained PCS and Ti powder in a high-temperature furnace, the pyrolysis atmosphere is argon, the heating rate is 8°C / min, from room temperature to 1080°C, and the temperature is kept for 100 minutes to obtain a SiC / TiC composite powder.

[0028] (3) Put the obtained composite powder into a graphite mold, put it into a hot-press sintering furnace, raise the temperature to 1550°C at a rate of 17°C / min under vacuum, fill it with argon, and sinter with a sintering pressure of 30MPa and keep it warm for 45 minutes. Obtain SiC / TiC composite ceramics. Th...

Embodiment 3

[0030] (1) 3.69 grams of PCS was added to 50 ml of cyclohexane, fully dissolved to prepare a PCS transparent solution, and then 2 grams of Ti powder was added to it. Heating while stirring, gradually raising the temperature to 65°C, keeping warm and stirring. Then put it into a drying oven and continue to evaporate the solvent for 60 minutes until the system is difficult to stir, and dry to obtain a mixture of PCS and Ti powder.

[0031] (2) Pyrolyze the mixture of the obtained PCS and Ti powder in a high-temperature furnace, the pyrolysis atmosphere is argon, the heating rate is 10°C / min, from room temperature to 1100°C, and the temperature is kept for 120 minutes to obtain a SiC / TiC composite powder.

[0032] (3) Put the obtained SiC / TiC composite powder into a graphite mold, put it into a hot-press sintering furnace, raise the temperature to 1600°C at 20°C / min under vacuum, fill it with argon, and sinter with a sintering pressure of 35MPa and a heat preservation temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com