In-situ (TiB2+SiC)/Ti3SiC2 complex phase ceramic material and preparation method thereof

A composite ceramics, in-situ technology, applied in the field of in-situ/Ti3SiC2 composite ceramic materials and its preparation, can solve the problems of microhardness and oxidation resistance of composite materials to be improved, and achieve low cost and good mechanical properties , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

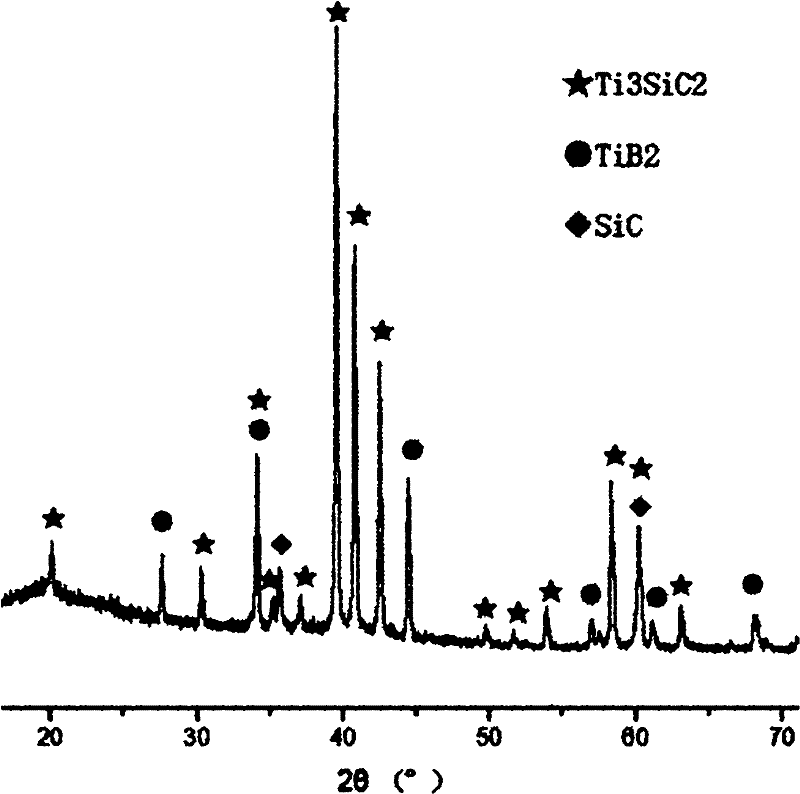

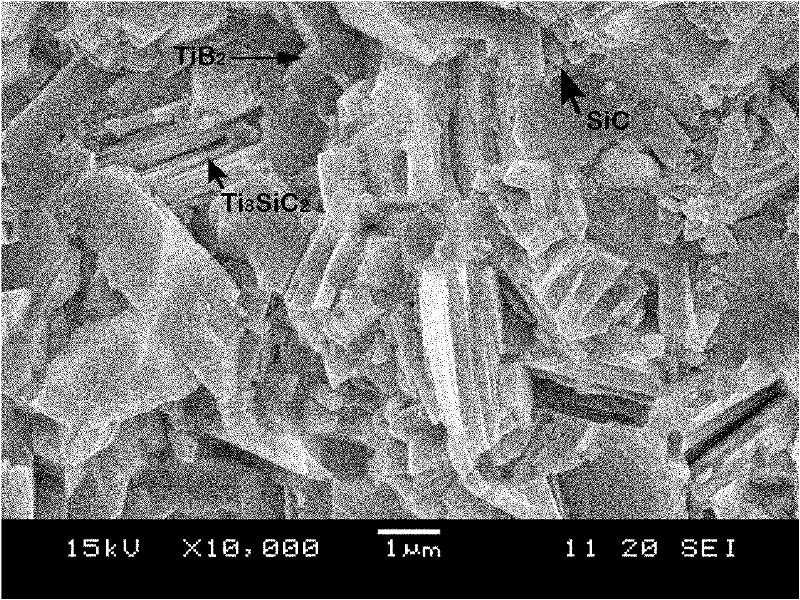

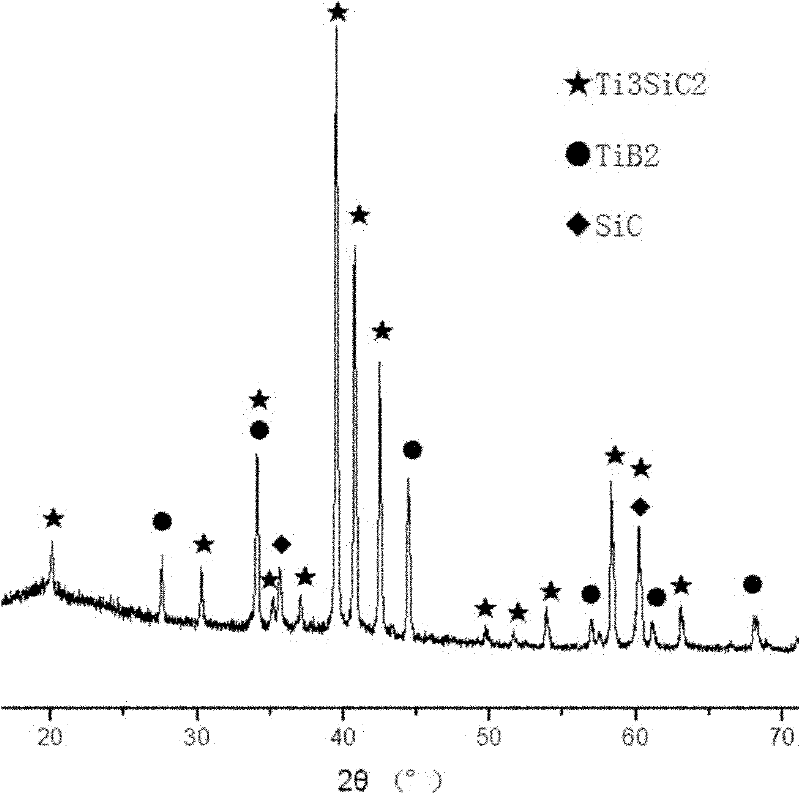

[0021] molar ratio n(TiH 2 ):n(Si):n(TiC):n(B 4 C):n(Al)=0.9194:1:1.5012:0.1833:0.1369 Weigh raw material TiH 2 powder (300 mesh), Si powder (300 mesh), TiC powder (1.5μm), B 4 After C powder (5μm) and Al powder (200 mesh), dry mix them in a polyethylene tank for 24 hours, place them in a BN-coated graphite mold for cold press molding, and hot press sinter in an argon atmosphere at 30°C / min The speed is raised to 850°C for 55 minutes without pressure, and then the temperature is raised to 1500°C at a rate of 30°C / min. After reaching the sintering temperature, the pressure is increased to 22MPa at a rate of 3MPa every 3 minutes, and the holding time is 1.5h . The density of the obtained bulk material reaches 99.7%, among which TiB 2 Accounting for 15% of the volume of the composite ceramic material, SiC accounts for 10% of the volume of the composite ceramic material; the three-point bending strength of the material tested on the universal testing machine is greater than 78...

Embodiment 2

[0023] molar ratio n(TiH 2 ):n(Si):n(TiC):n(B 4 C): n(Al)=1.2003:1:1.5994:0.2003:0.15994 Weigh raw material TiH 2 powder (300 mesh), Si powder (300 mesh), TiC powder (1.5μm), B 4 C powder (5μm) and Al powder (-200 mesh) were dry mixed in a polyethylene tank for 24 hours, then placed in a BN-coated graphite mold for cold pressing, and then hot-pressed and sintered in an argon atmosphere at 50°C / min The speed is raised to 900°C for 50 minutes without pressure, and then the temperature is raised to 1450°C at a rate of 20°C / min. After reaching the sintering temperature, the pressure is increased to 24MPa at a rate of 2.5MPa every 5 minutes, and the holding time is 1.8 h. The density of the obtained bulk material reaches 99.7%, among which TiB 2 Accounting for 14.5% of the volume of the composite ceramic material, SiC accounts for 5% of the volume of the composite ceramic material; the three-point bending strength of the material tested on the universal testing machine is great...

Embodiment 3

[0025] molar ratio n(TiH 2 ):n(Si):n(TiC):n(B 4 C): n(Al)=1.1998:1:1.6011:0.2005:0.15994 Weigh raw material TiH 2 powder (300 mesh), Si powder (300 mesh), TiC powder (1μm), B 4 C powder (10 μm) and Al powder (200 mesh) were dry-mixed in a polyethylene tank for 24 hours, then placed in a BN-coated graphite mold for cold pressing, and then hot-pressed and sintered in an argon atmosphere at a temperature of 30 °C / min. The rate was raised to 900°C for 60 minutes without pressure, and then the temperature was raised to 1400°C at a rate of 50°C / min. After reaching the sintering temperature, the pressure was increased to 25MPa at a rate of 3MPa every 4 minutes, and the holding time was 2h. The density of the obtained bulk material reaches 99.6%, among which TiB 2 Accounting for 14.5% of the volume of the composite ceramic material, SiC accounts for 5% of the volume of the composite ceramic material; the three-point bending strength of the material tested on the universal testing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com