Curing method of active nucleus waste matter simulation substance

A technology of radionuclide and solidification method, used in radioactive purification, nuclear engineering and other directions, can solve problems such as long half-life, and achieve the effects of high crystallinity, uniform microstructure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

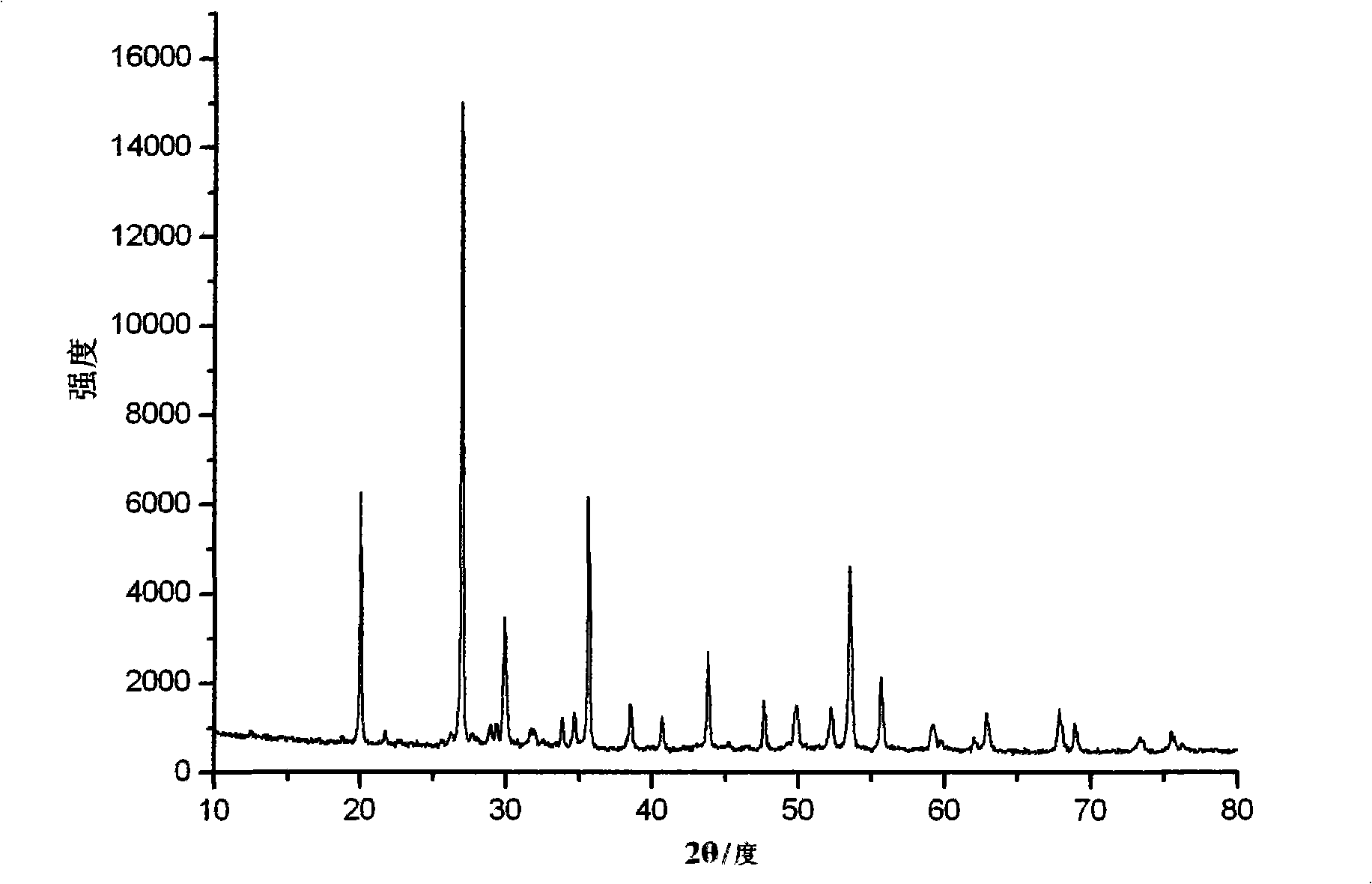

[0031] A method for immobilizing radioactive nuclear waste simulants, comprising the following steps:

[0032] a. Weigh ZrO according to the molar ratio of 1:1:0.01 2 : 30.8057g, SiO 2 : 15.0211g, Eu 2 o 3 : 2.1996, added to a 500ml nylon ball mill tank containing 70ml alcohol, and added ZrO with a corresponding mass diameter of 4mm according to the mass ratio of 1:2.5. 2 small ball;

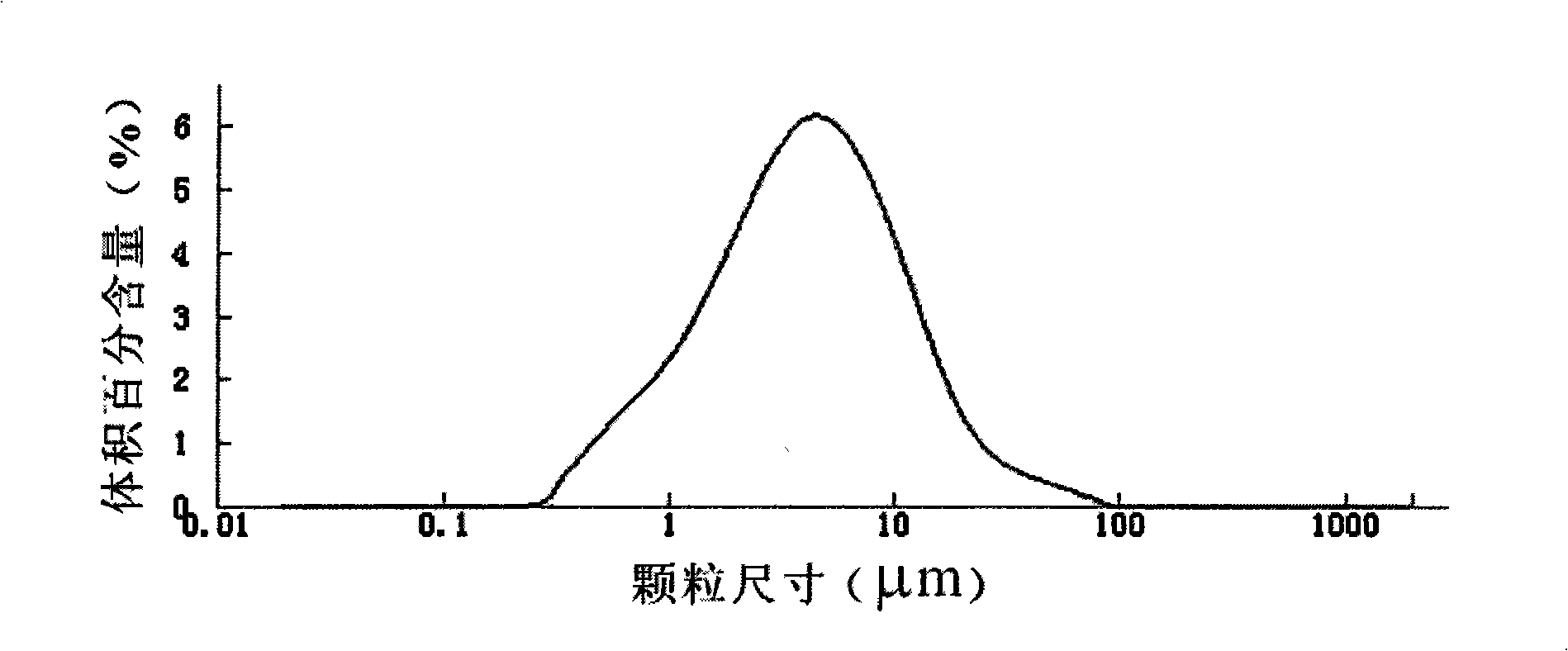

[0033] b. On the QM-1SP ball mill produced by Nanjing University, the raw material was wet ball milled at a speed of 240r / min for 24 hours; the ball milled material was dried in an oven at 100°C, and the particle size distribution curve of the obtained mixed raw material was as follows figure 1 shown;

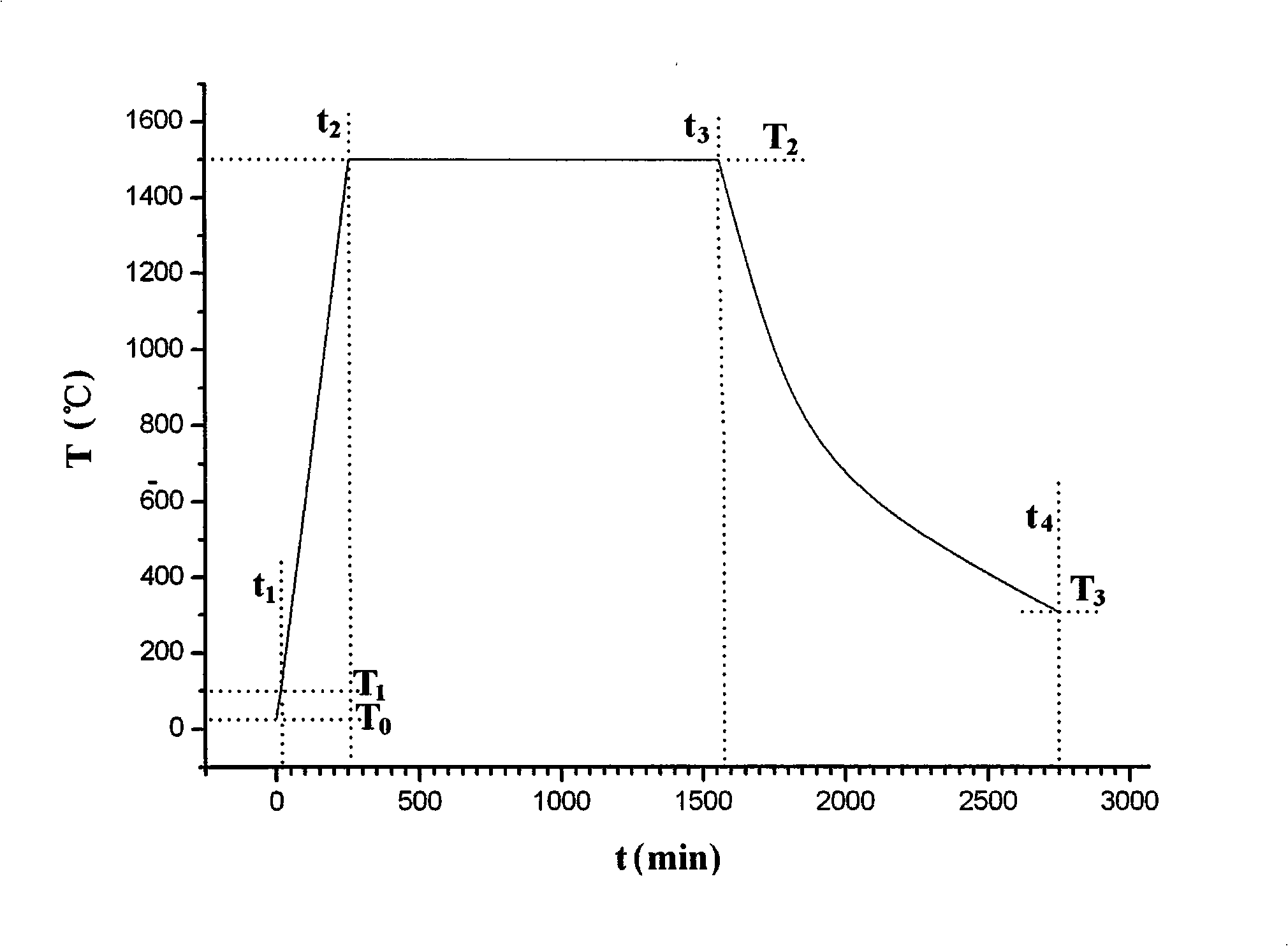

[0034] c. Add the mixed raw materials into two corundum crucibles with a volume of 80ml, and the amount of sample added shall not exceed 2 / 3 of the volume of the crucible, and then put the crucible with the sample into the SX-12-16 box-type resistance furnace for High temperature synthesis,...

Embodiment 2

[0037] A method for immobilizing radioactive nuclear waste simulants, comprising the following steps:

[0038] a. Weigh ZrO according to the molar ratio of 1:1:0.02 2 : 30.8057g, SiO 2 : 15.0211g, CeO 2 : 2.1514, join in the 500ml nylon ball mill jar that 70ml alcohol is housed, add the ZrO that the corresponding mass diameter is 4mm according to the material-ball ratio that is 1: 2.5 by mass ratio 2 small ball;

[0039] b. On the QM-1SP ball mill produced by Nanjing University, the raw material was wet ball milled at a speed of 240r / min for 24 hours; the ball milled material was dried in an oven at 100°C, and the particle size distribution curve of the obtained mixed raw material was as follows Figure 6 shown;

[0040] c. Add the mixed raw materials into two corundum crucibles with a volume of 80ml, and the amount of sample added shall not exceed 2 / 3 of the volume of the crucible, and then put the crucible with the sample into the SX-12-16 box-type resistance furnace for...

Embodiment 3

[0043] A method for immobilizing radioactive nuclear waste simulants, comprising the following steps:

[0044] a. Ingredients: according to SiO 2 : ZrO 2 :Eu 2 o 3 The molar ratio of SiO is 1:1:0.2 2 , ZrO 2 and Eu 2 o 3 Powder (the maximum particle size of each raw material component before ball milling is controlled below 1mm, if the maximum particle size of the raw material before ball milling is above 1mm, pretreatment such as jaw crushing should be performed in advance to make the maximum particle size of the raw material below 1mm), placed in a ball mill;

[0045] B, grinding: take dispersing agent deionized water according to the ratio of solid-liquid mass ratio 1: 2, inject in the ball mill, add grinding ball [according to the material ball mass ratio of 1: 2.5, add corresponding quality, the diameter is the zirconia of 4mm ( ZrO 2 ) ball], ball milling for 25 hours until the average particle size of the mixed powder is less than 20 μm (the particle size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com