Nickel ferrite-copper metal ceramic inert anode material and preparation method

A technology of inert anode and nickel ferrite, which is applied in the field of nickel ferrite-copper cermet inert anode material and preparation technology, can solve problems such as Ni electrochemical corrosion, achieve the improvement of electrical conductivity and thermal shock resistance, and improve the microstructure The effect of uniformity, electrical conductivity and thermal shock resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Adding copper oxide to improve the wettability of nickel ferrite and copper melt

[0034] The nickel ferrite ceramic powder was prepared by high temperature solid phase sintering synthesis method. The synthetic powder was crushed by ball milling, then pressed, degreased, and sintered in a nitrogen atmosphere at 1350°C for 4 hours to obtain a ceramic sample with a density of more than 96%. The sintered samples were cut and sampled, and oxidized in air at 1000°C for 72 hours after polishing. Mix cuprous oxide and copper at a mass ratio of 8:92, and copper oxide and copper at a mass ratio of 4:96, respectively, and press to form. The wetting angle between nickel ferrite and copper melt was measured by the sessile drop method, and the atmosphere was a nitrogen atmosphere with an oxygen partial pressure of 10Pa. The temperature was raised from room temperature to 1050°C at a rate of 10°C / min, and then at a rate of 2°C / min. When the temperature rises to 1150°C, ...

Embodiment 2

[0035] Embodiment 2: Control the sintering atmosphere to improve the wettability of nickel ferrite and copper melt

[0036] Nickel ferrite ceramic powder was prepared by high-temperature solid-phase sintering synthesis method. The synthetic powder was crushed by ball milling, then pressed, degreased, and sintered in a nitrogen atmosphere at 1350°C for 4 hours. The sintered sample was cut and sampled, and polished in the air at 1000°C. Medium oxidation for 72h. Copper powder is pressed into shape. The wettability of nickel ferrite and copper melt was measured by the sessile drop method, the atmosphere was a nitrogen atmosphere with an oxygen partial pressure of 800Pa, and a heating rate of 3°C / min was adopted. When the temperature rises to 1150°C, the wetting angle can be reduced to 0°.

Embodiment 3

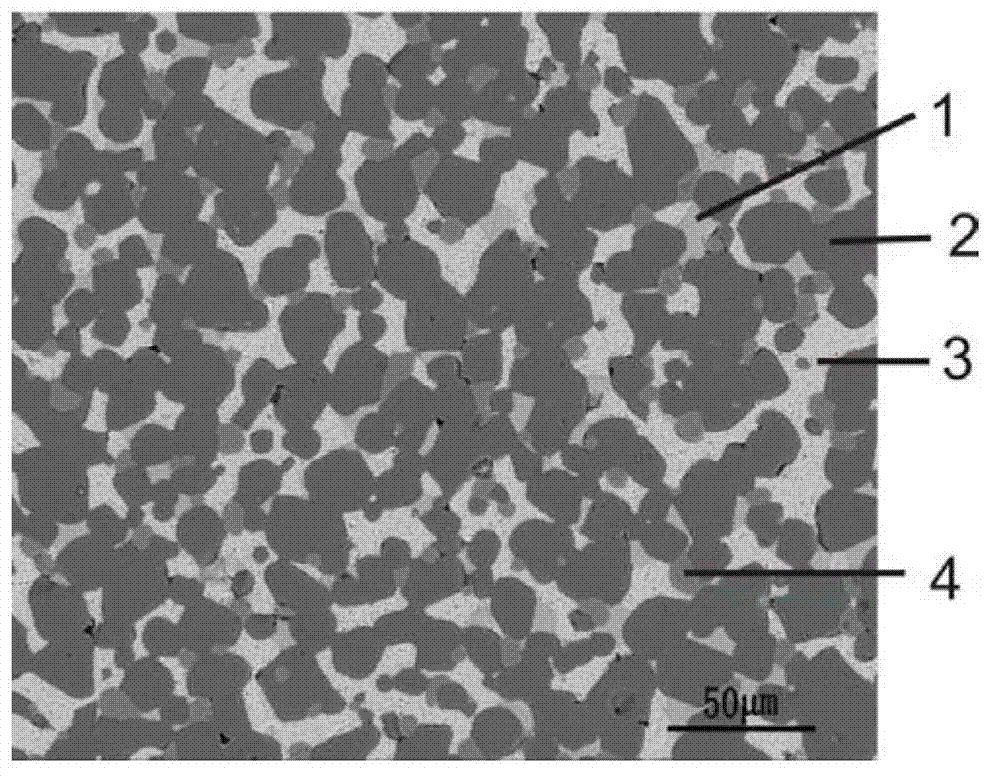

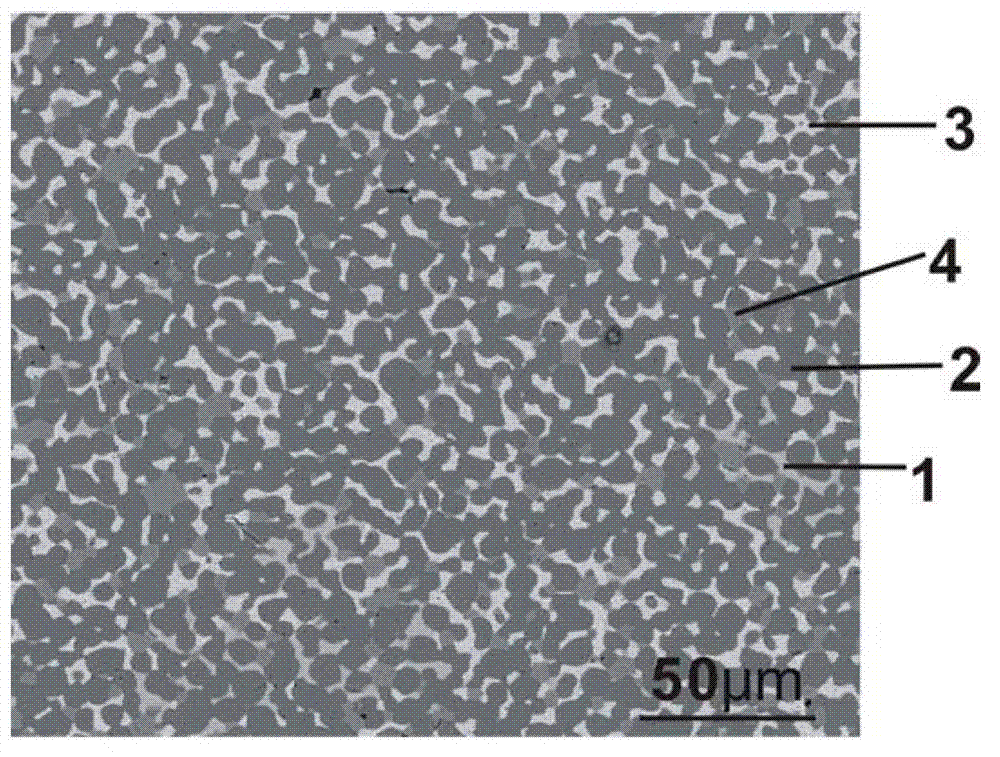

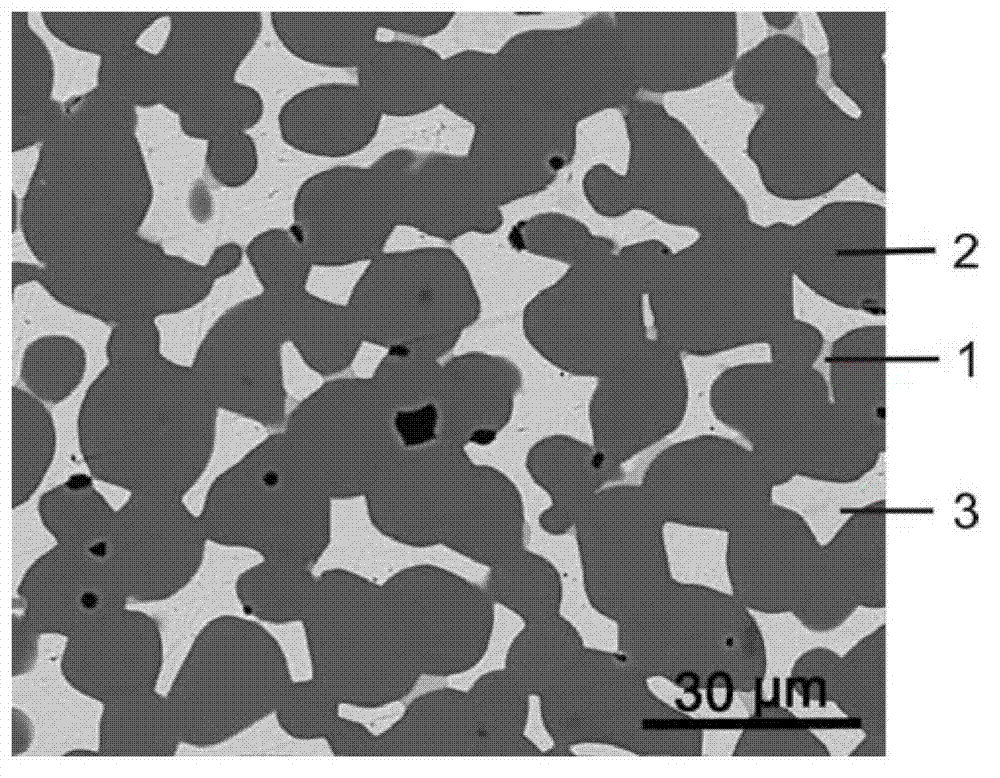

[0037] Example 3: Cu / NiFe 2 o 4 Preparation of -10NiO cermet material

[0038] The first step: raw material preparation

[0039] According to the designed ceramic phase and metal phase mass ratio, take NiFe respectively 2 o 4 -10NiO composite ceramic powder and metal copper, the average particle size of the ceramic powder is about 15 μm; the average particle size of the metal copper is about 8 μm;

[0040] The second step: billet

[0041] To NiFe 2 o 4 -10NiO composite ceramic powder is added with a forming agent, press-formed and degreased according to the conventional powder metallurgy blank-making process to obtain a degreased ceramic body; the degreasing temperature is 500°C, the holding time is 4 hours, and the heating rate is 1°C / min; NiFe 2 o 4 -10NiO composite ceramic degreased body was heated to 800°C, kept for 2 hours, and after cooling, a ceramic preform with a porosity of 36% was obtained;

[0042] Metal copper is cold-pressed and formed under a pressure o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com