Method for controlling air holes of laser cladding layer by intermittent parking machine

A technology of laser cladding and mechanical vibration, which is applied in coating, metal material coating process, etc., can solve the undiscovered problems of reducing the porosity in the laser cladding layer and eliminating the surface porosity, so as to improve the fluidity , compact microstructure and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

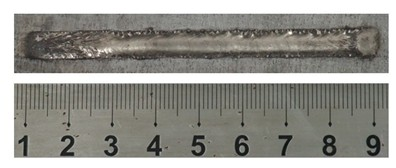

[0020] Embodiment 1: The laser cladding of Ni60CuMoW self-fluxing alloy is carried out on the 45 steel plate substrate with the size of 100mm×40mm×6mm through the method of controlling the pores of the laser cladding layer through the intermittent resident mechanical vibration. The cladding material used is Ni60CuMoW self-fluxing alloy powder with a melting point of 1024 °C and an average particle size of 80 μm (mass percentage components: Cr14~19%, Si3.5~5.0%, B3.0~4.5%, C0.5~1.0% , Fe<8.0%, Cu2~4%, Mo2~4%, W2~3%, the balance Ni).

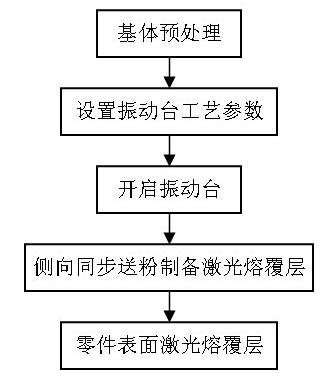

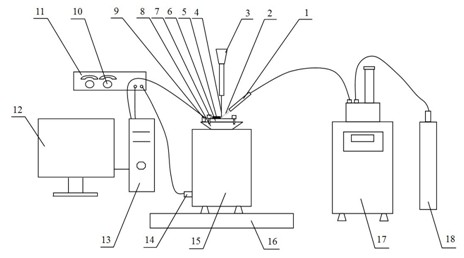

[0021] see figure 1, the method of intermittently resident mechanical vibration to control the pores of the laser cladding layer is to use the lateral synchronous powder feeding carbon dioxide laser cladding equipment while intermittently resident A Ni60CuMoW alloy cladding layer was prepared on the surface. The specific steps are: first, pretreat the surface of the 45 steel plate matrix 6, clean the surface with acetone, and use the clamp devic...

Embodiment 2

[0024] Example 2: This method of intermittent resident mechanical vibration to control the pores of the laser cladding layer, the cladding material, the process used and the equipment used are all the same as in Example 1. The amplitude of the mechanical vibration is 60 μm, the frequency is 200 Hz, and the intermittent resident The pause-dwell interval of mechanical vibration is 1 second. The macroscopic morphology of the obtained cladding layer is shown in Figure 5 In (b) shown. Microstructures scanned using a scanning electron microscope such as Figure 7 shown.

Embodiment 3

[0025] Example 3: This method of intermittent resident mechanical vibration to control the pores of the laser cladding layer. The cladding materials, process and equipment used are the same as in Example 1. The amplitude of the mechanical vibration is 60 μm, the frequency is 300 Hz, and the intermittent resident The pause-dwell interval of mechanical vibration is 1 second. The macroscopic morphology of the obtained cladding layer is shown in Figure 5 In (c) shown. Microstructures scanned using a scanning electron microscope such as Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com